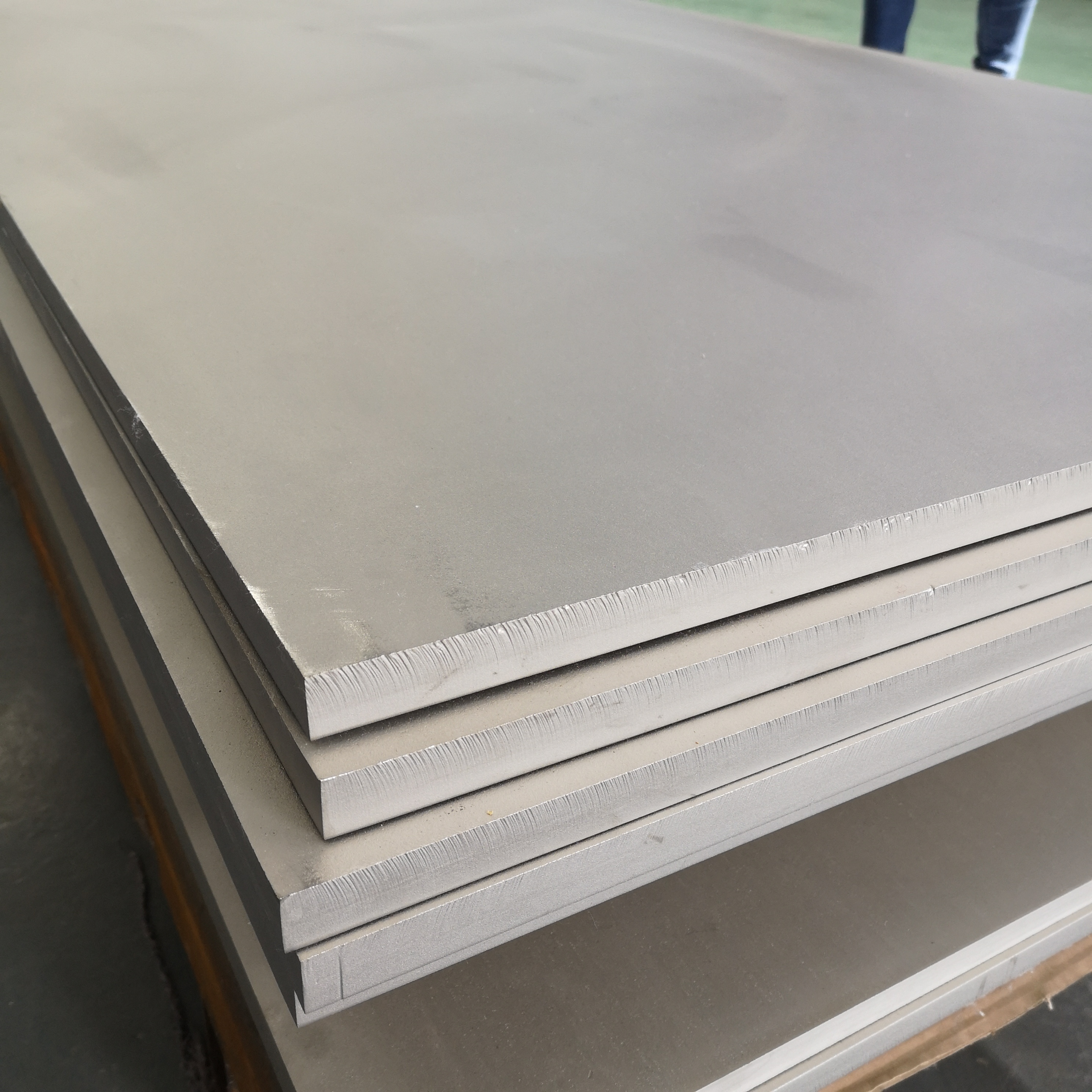

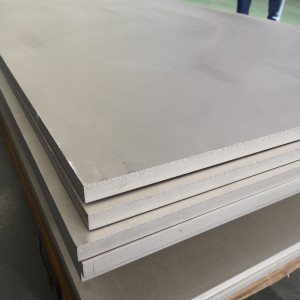

Lembaran / Plat Titanium

Kelas umum

Titanium Grade 1punika unalloyed, kurang kekuatan produk titanium ngemot kurang oksigen karo dhuwur wangun kemampuan;bahan titanium iki digunakake ing pigura online, ijol-ijolan panas lan Unit desalination.

Titanium Kelas 2punika unalloyed, medium kekuatan produk titanium.Bahan titanium iki digunakake ing pigura udara, mesin pesawat lan bagean laut;kemampuan las apik lan resistance karat sing ciri khas.

Titanium Kelas 3punika unalloyed, kekuatan dhuwur, produk titanium nyediakake resistance karat banget lan kemampuan las apik.Bahan titanium iki utamane digunakake ing pigura udara lan bagean mesin pesawat.

Titanium Kelas 4produk titanium unalloyed murni kekuatan paling dhuwur.Kelas titanium iki digunakake meh khusus kanggo pigura udara, bagean mesin pesawat, laut, implan bedah, pipa hidrolik.Kemampuan wangun apik lan tahan karat minangka ciri khas.

Titanium Grade 5 (6AL-4V)minangka produk titanium alloy sing ngemot 6% Aluminium lan 4% Vanadium;minangka produk kekuatan medium.Bahan titanium iki umume digunakake ing bagean mesin pesawat lan turbin;lan digunakake ing implan bedhah.Info Teknis Titanium 6AL–4V ELI minangka produk titanium paduan sing ngemot 6% Aluminium lan 4% Vanadium, ELI (Extra Low Interstitial).

6AL–2 Sn–4Zr–2Bulan (6-2-4-2)minangka produk titanium paduan sing ngemot 6% Aluminium, 2% Timah, 4% Zirkonium, 2% Molybdenum.

6AL–6V–2Sn (6-6-2)minangka produk titanium paduan sing ngemot 6% Aluminium, 6% Vanadium, 2% Timah.

5AL–2.5Sn & ELI (5-2.5)minangka produk titanium paduan sing ngemot 5% Aluminium lan 2,5% Timah.Uga ELI (Extra Low Interstitial).

8AL–1V–1Bulan (8-1-1)minangka produk titanium alloy sing ngemot 8% Aluminium, 1% Molybdenum lan 1% Vanadium.

15V–3Cr–4AL–3Sn (15-3-4-3)minangka produk titanium paduan sing ngandhut 15% Vanadium, 3% Chromium, 4% Aluminium, 3% Tin.

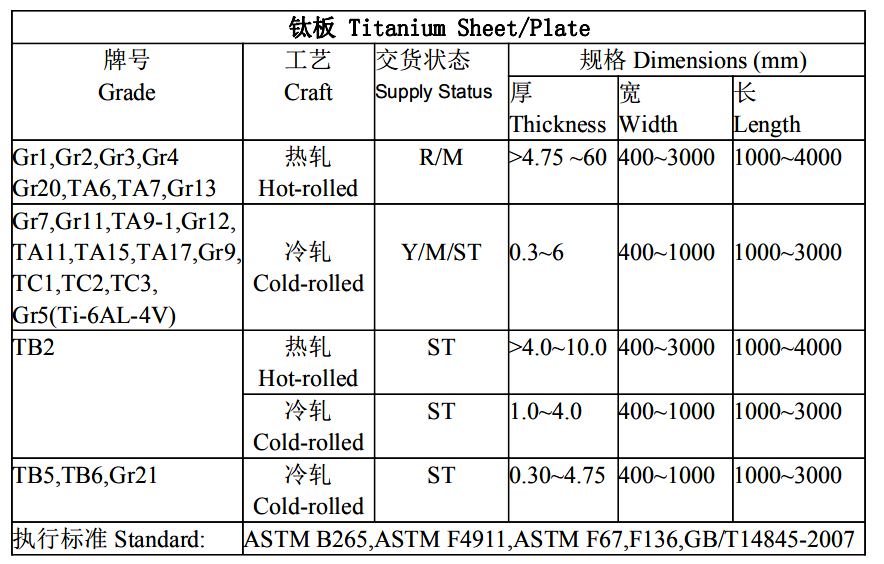

| sasmita | Status | Spesifikasi | ||

| Gr1, Gr2, Gr4, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 | Hot Rolled (R) Cold Rolled (Y) Annealed (M) Pengobatan solusi (ST) | Ketebalan (mm) | Jembar (mm) | dawa (mm) |

| 0.3-60 | ≥400 | ≤ 6000 | ||

| Lembaran Titanium | |||

| kekandelan | biji | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Cathetan: Ukuran tambahan kasedhiya, ora kabeh ukuran sing ditampilake kasedhiya saka saham.Hubungi kita kanggo mriksa kasedhiyan.

| AMS:AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1EN:EN 10204.3, EN 1-204:2005 3.1 NACE:NACE MR0175 ASME:ASME SB265 |

| sasmita | Spesifikasi AMS/MIL | Spesifikasi ASTM |

| kelas 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 | ASTM B265 Gr1 Lembar/piring Pipa ASTM B337 Gr1 Tabung ASTM B338 Gr1 ASTM B348 Gr1 bar Implan Bedah ASTM F67 Gr1 |

| kelas 2 | Kelas 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 AMS 4941 AMS 4942 AMS 4951 Welding wire | ASTM B265 Gr2 Lembar/piring Pipa ASTM B337 Gr2 Tabung ASTM B338 Gr2 ASTM B348 Gr2 bar Implan Bedah ASTM F67 Gr2 |

| kelas 3 | AMS-T-9046B CP2 AMS 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 Lembar/piring Pipa ASTM B337 Gr3 Tabung ASTM B338 Gr3 ASTM B348 Gr3 bar Implan Bedah ASTM F67 Gr3 |

| kelas 4 | AMS-T-9046B CP1 AMS-T-9047A CP70 AMS 4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 | ASTM B265 Gr4 Lembar/piring Pipa ASTM B337 Gr4 Tabung ASTM B338 Gr4 ASTM B348 Gr4 bar Implan Bedah ASTM F67 Gr4 |

| Kelas 7 | ASTM B265 Gr7 Lembar/piring Pipa ASTM B337 Gr7 Tabung ASTM B338 Gr7 ASTM B348 Gr7 bar |

| sasmita | Spesifikasi AS | Spesifikasi ASTM |

| Kelas 5 6Al-4V | AMS 4907 ELI AMS 4911 AMS 4928 AMS 4930 ELI AMS 4931 ELI Duplex ann AMS 4963 AMS 4965 AMS 4967 AMS 4985 AMS 4991 AMS 6931 AMS 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Tipe 3 Comp C MIL-T-9046H Tipe 3 Comp D AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 Lembar/piring ASTM B348 Gr5 bar Kelas Implan ASTM F136 Gr5 |

| Kelas 9 3Al-2.5V | AMS 4943 AMS 4944 AMS 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 Lembar/piring ASTM B348 Gr6 bar |

| Kelas 23 6Al-4V ELI | AMS 4907 AMS 4930 AMS 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 lembar/piring/strip ASTM B348 Gr23 bar/billet ASTM F136 Gr23 Implan Gra |

Komposisi kimia

| sasmita | Komposisi kimia, persen bobot (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Unsur liyane Maks.saben | Unsur liyane Maks.gunggung | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | 0.12~0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04~0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.1 |

Sifat fisik

| sasmita | Sifat fisik | ||||||

| Kekuatan tarik Min | kekuatan ngasilaken (0,2%, offset) | Elongation ing 50mm Min (%) | |||||

| ksi | MPa | Min | Maks | ||||

| ksi | MPa | ksi | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | — | — | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | — | — | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | — | — | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | — | — | 10 |

Toleransi (mm)

| kekandelan | Toleransi jembar | ||

| 400~1000 | 1000~2000 | > 2000 | |

| 5.0~6.0 | ± 0,35 | ± 0,40 | ± 0,60 |

| 6.0~8.0 | ± 0,40 | ± 0,60 | ± 0,80 |

| 8.0~10.0 | ± 0,50 | ± 0,60 | ± 0,80 |

| 10.0~15.0 | ± 0,70 | ± 0,80 | ± 1.00 |

| 15.0~20.0 | ± 0,70 | ± 0,90 | ± 1.10 |

| 20.0~30.0 | ± 0,90 | ± 1.00 | ± 1.20 |

| 30.0~40.0 | ± 1.10 | ± 1.20 | ± 1,50 |

| 40.0~50.0 | ± 1.20 | ± 1,50 | ± 2.00 |

| 50.0~60.0 | ± 1,60 | ± 2.00 | ± 2,50 |