EN 10204 Pipa Seamless

| Ukuran | OD | 1/2" -24" (13.7mm-609.6mm) |

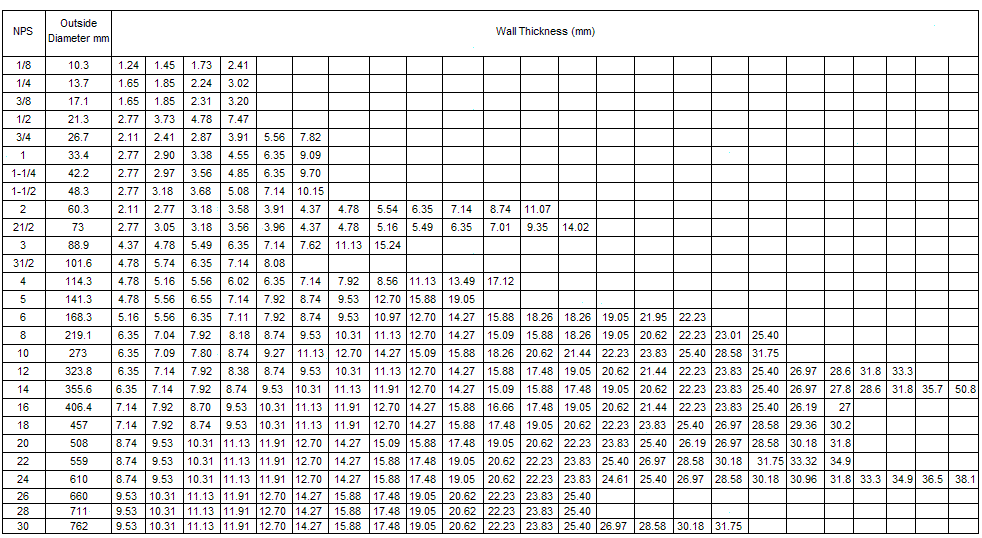

| Kekandelan tembok | 1.6mm-28mmSCH20,SCH40,STD,XS,SCH80,SCH160,XXS | |

| dawa | 5.8M Length, 6M Length utawa 12M Length utawa kaya sing dijaluk | |

| Bahan baja | 20#, 16Mn, St37, St52, St44, lsp | |

| Standar | API 5L, ASTM A53, ASTM A106, GB/T 8163, GB/T 8162, DIN 17175, DIN 2448 etc | |

| PRODUKTIVITAS | 5000MTONS saben wulan | |

| Panggunaan | 1) Cairan tekanan rendah, banyu, gas, minyak, pipa saluran 2) konstruksi3) pager, pipa lawang | |

| mungkasi | 1) Plain2) Beveled3) Thread karo Coupling utawa cap4) Chamfer5) Groove6) Screw | |

| Pelindung pungkasan | 1) tutup pipa plastik2) soket baja | |

| Perawatan lumahing | 1) Bared2) Ireng Painted (varnish coating)3) panas dicelup Galvanized4) Oiled5) PE,3PE, FBE, karat lapisan tahan, lapisan Anti karat. | |

| Jinis | kadhemen digambar, panas mbalek | |

| Bentuk bagean | Babak | |

| Inspeksi | Kanthi Tes Hidrolik, Eddy Current, Infrared Test | |

| Tanggal Pangiriman | Ing 30 dina lan Gumantung ing jumlah pesenan. | |

Sawetara Ukuran EN 10204 Hot Rolled Steel Pipe

| Nominal | Ukuran pipa | OD mm | Jadwal STD | Jadwal 40 | Jadwal 60 | Jadwal Tambahan | Kuat (XS) | |||

| Mm | inch | Tembok | Wt. | Tembok | Wt. | Tembok | Wt. | Tembok | Wt. | |

| 3 | 1/8 | 10.3 | 1.73 | 0.37 | 1.73 | 0.357 | 2.41 | 0.47 | ||

| 6 | ¼ | 13.7 | 2.24 | 0.63 | 2.24 | 0.625 | 3.02 | 0.804 | ||

| 10 | 3/8 | 17.1 | 2.31 | 0.84 | 2.31 | 0.84 | 3.2 | 1.1 | ||

| 15 | ½ | 21.3 | 2.77 | 1.26 | 2.77 | 1.26 | 3.73 | 1.62 | ||

| 20 | ¾ | 26.7 | 2.87 | 1.69 | 2.87 | 1.68 | 3.91 | 2.2 | ||

| 25 | 1 | 33.4 | 3.38 | 2.5 | 3.38 | 2.5 | 4.55 | 3.24 | ||

| 32 | 1 1/4 | 42.2 | 3.56 | 3.39 | 3.56 | 3.38 | 4.85 | 4.47 | ||

| 40 | 1 1/2 | 48.3 | 3.68 | 4.05 | 3.68 | 4.05 | 5.08 | 5.41 | ||

| 50 | 2 | 60.3 | 3.9 | 5.44 | 3.9 | 5.44 | 5.5 | 7.48 | ||

| 65 | 2 1/2 | 73 | 5.2 | 8.63 | 5.16 | 8.63 | 7 | 11.41 | ||

| 80 | 3 | 88.9 | 5.5 | 11.3 | 5.5 | 11.3 | 7.62 | 15.3 | ||

| 90 | 31/2 | 1.6 | 5.74 | 13.57 | 5.74 | 13.57 | 8.08 | 18.63 | ||

| 100 | 4 | 114.3 | 6.02 | 16.07 | 6.02 | 16.07 | 8.56 | 22.3 | ||

| 125 | 5 | 141.3 | 6.6 | 21.77 | 6.55 | 21.77 | 9.53 | 30.9 | ||

| 150 | 6 | 168.3 | 7.11 | 28.26 | 7.11 | 28.26 | 10.97 | 42.5 | ||

| 200 | 8 | 219.1 | 8.2 | 42.5 | 8.2 | 42.5 | 10.3 | 53.1 | 12.7 | 64.6 |

| 250 | 10 | 273 | 9.27 | 60.3 | 9.27 | 60.3 | 12.7 | 81.5 | 12.7 | 81.5 |

| 300 | 12 | 323.9 | 9.53 | 73.8 | 10.3 | 79.7 | 14.3 | 109 | 12.7 | 97.4 |

| 350 | 14 | 355.6 | 9.53 | 81.3 | 11.13 | 94.3 | 15.1 | 126.4 | 12.7 | 107 |

| 400 | 16 | 406.4 | 9.53 | 93.3 | 12.7 | 123 | 16.7 | 160 | 12.7 | 123 |

| 450 | 18 | 457.2 | 9.53 | 105 | 14.3 | 156 | 19 | 206 | 12.7 | 130 |

| 500 | 20 | 508 | 9.53 | 177.2 | 15.1 | 183 | 20.6 | 248 | 12.7 | 155.1 |

| 550 | 22 | 558.8 | 9.53 | 129 | 22.2 | 294 | 12.7 | 171 | ||

| 600 | 24 | 609.6 | 9.53 | 141 | 17.4 | 255 | 24.5 | 355 | 12.7 | 187 |

Ringkesan syarat dokumentasi kanggo EN 10204:2004

| EN 10204 | Tipe Dokumentasi | Konten Dokumen | Wewenang dening |

| Tipe 2.1 | Sertifikat saka Kepatuhan | Pranyatan selaras karo pesenan | Produsen |

| Jinis 2.2 | Bahan | Pranyatan kepatuhan karo pesenan lan indikasi asil pemeriksaan non-spesifik | Produsen |

| Tipe 3.1 | Sertifikat Inspeksi | Pranyatan selaras karo urutan lan indikasi asil tes sing ditindakake kaya sing ditetepake dening spesifikasi produk | Perwakilan sah saka pabrikan, independen saka departemen manufaktur |

| Jinis 3.2 | Sertifikat Inspeksi | Pranyatan selaras karo pesenan, indikasi asil tes sing ditindakake kaya sing ditetepake dening spesifikasi produk lan indikasi saksi Pihak Ketiga kanggo ruang lingkup tes sing ditemtokake panuku. | Perwakilan resmi pabrikan, independen saka departemen manufaktur lan wakil resmi utawa inspektur panuku sing ditunjuk dening peraturan resmi. |

Bared, Galvanis, Oiled, Cat Warna, 3PE;Utawa Perawatan Anti-korosif Liyane