Pipa slotted

Pipa casing slotted digunakake ing eksplorasi lenga bisa nyegah 99% wedhi, ngurangi 80% saka pangopènan abot sumur lenga, uga nambah kekuatan saka sumur lenga, integralitas lan stabilitas tetep wedhi mati.Kangge, teknologi incision laser bisa nggawe slot dadi Gamelan lan tliti.Struktur pipa casing slotted minangka conto, nanging kerjane efisien banget.

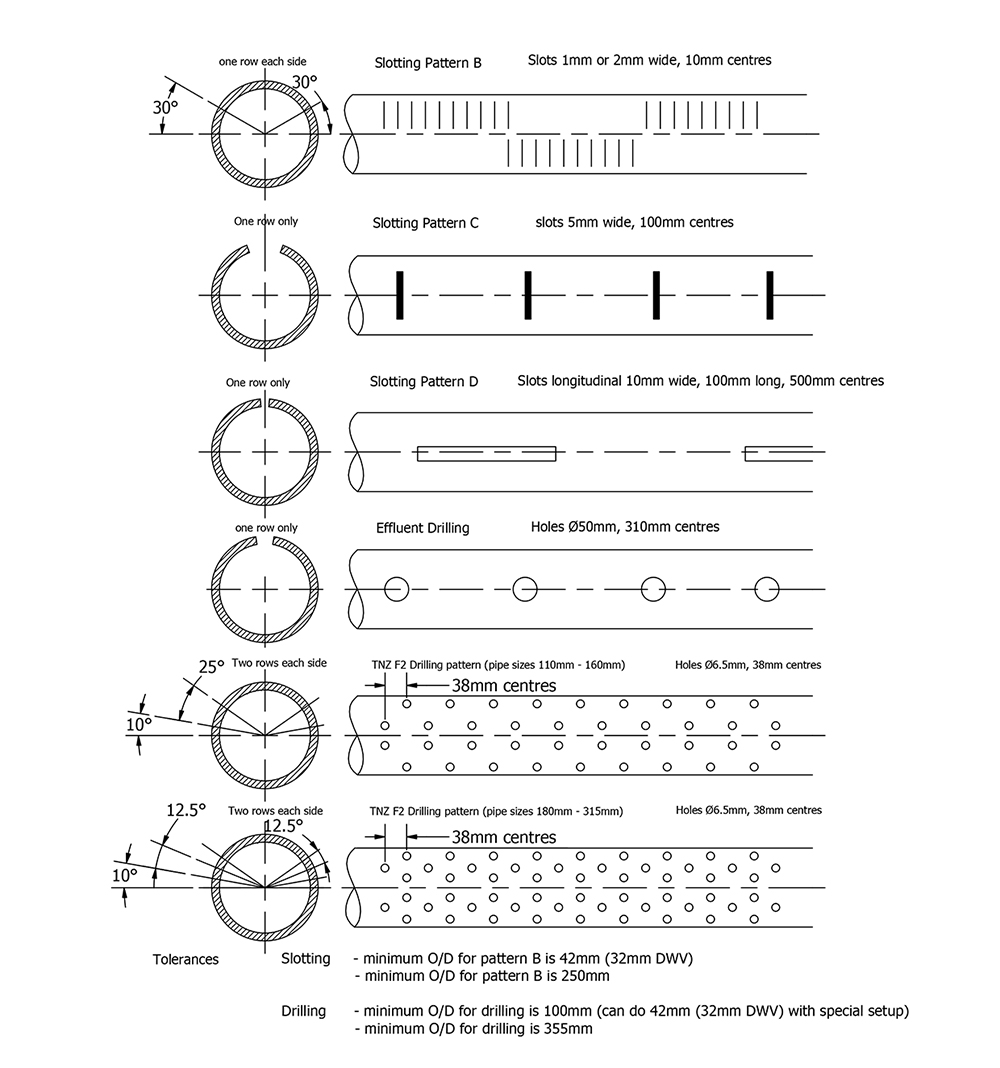

Processing tabung Slotted ing awak baja kekuatan dhuwur karo cara kerja kadhemen utawa panas, nglereni metu atusan ewu retak longitudinal, retak umum digunakake specifications kanggo: jembaré lapisan 0,15 3 mm, malah luwih amba, dawa longkangan 50-200 mm. jinis punika: persegi dowo, andha shaped, tartamtu lan macem-macem, uga wis layar alur bunder, aperture diameteripun specifications sawetara 5-20 mm ing meter.Slotted tabung sieve bolongan jahitan kualitas nglereni utamané gumantung ing tliti saka jembaré jahitan, bolongan jahitan cross- wangun bagean gelar rapi, ing pinggiran bolongan lapisan Gamelan lan jurusan resistance karat lapisan bolongan.

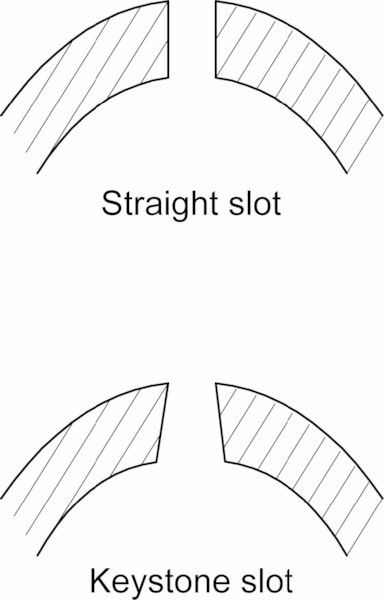

Lurus Slot–Slot sing Cut karo jembaré witjaksono liwat tembok saka pipe loro ID lan OD.Ditemtokake ngendi wedhi wedhi bridging ing slot ora wigati utama, terus slot luwih nyandhang-tahan saka seamed keystone slot lan kurang larang regane kanggo gawé.Aplikasi umum saka slot potong Lurus yaiku kanggo Produksi Dingin lan sumur horisontal CBM saliyane sumur injektor SAGD.

Slot Keystone Seamed–- digiling luwih akeh ing interior pipa lan ngresiki dhewe kanggo nyegah plugging.Sempit ing lumahing liner lan nambah ing jembaré ing interior, padha supaya wedhi sing mlebu pass gampang liwat slot tanpa plugging.

| Pipa Casing API | ID | dawa | Slot Length | Slot No. | jembaré Slot | Slot | Filter sing bener | Maks. | ||

| Spec mm | kekandelan | Per Bobot | ||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ± 50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

| 88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

| 101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

| 127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

| 139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

| 9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

| 168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

| 177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

| 9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

| Ukuran pipa Sreen (in) | OD (mm) | Ketebalan dinding (mm) | ID (mm) | Nomer jahitan saben bunder | Jembaré slot (mm) | dawa slot (mm) | dawa (mm) |

| 2-3/8″ | 60.3 | 4.83 | 50.64 | 12~18 | 0.2~0.8 | 45~100 | 1000~12000 |

| 2-7/8″ | 73 | 5.51 | 61.98 | 20~24 | 45~100 | ||

| 3-1/2" | 88.9 | 6.45 | 76 | 24~28 | 45~100 | ||

| 4″ | 101.6 | 6.65 | 88.29 | 24~30 | 45~100 | ||

| 4-1/2" | 114.3 | 5.69 | 102.92 | 24~30 | 45~100 | ||

| 6.35 | 101.6 | 45~100 | |||||

| 7.37 | 99.57 | 45~100 | |||||

| 8.56 | 97.18 | 45~100 | |||||

| 5″ | 127 | 5.59 | 115.82 | 28~36 | 0.25~0.8 | 45~100 | |

| 6.43 | 114.15 | 45~100 | |||||

| 7.52 | 111.96 | 45~100 | |||||

| 9.19 | 108.61 | 45~100 | |||||

| 5-1/2" | 139.7 | 6.2 | 127.3 | 30~38 | 45~100 | ||

| 6.99 | 125.73 | 45~100 | |||||

| 7.72 | 124.26 | 45~100 | |||||

| 9.17 | 121.36 | 45~100 | |||||

| 10.54 | 118.62 | 45~100 | |||||

| 7″ | 177.8 | 6.91 | 163.98 | 36~50 | 45~100 | ||

| 8.05 | 161.7 | 45~100 | |||||

| 9.19 | 159.41 | 45~100 | |||||

| 10.36 | 157.07 | 45~100 |

1. Pipa perforated kita nggunakake J55 / K55 / N80 casing lan tubings saka standar API, karo kekuatan sakabèhé High, ora supaya gampang kanggo deformasi.

2. Pojok slot vertikal, Gamelan, tanpa burrs, lan slot punika uniformity.

3. Pipa perforated cocok kanggo sumur pasir, sing diametere pasir luwih saka 0.3mm.

4. Slot bisa longitudinal lan transverse, bagean slot bisa podo karo lan trapezoidal jinis, karo area mbukak sudhut.

5. Pipa layar Slotted wis diameteripun utama amba.

Spesifikasi API 5CT–Spesifikasi 5CT/ISO 11960, Spesifikasi Casing and Tubing, Eighth Edition, Petroleum and natural gas industries - Pipa baja kanggo digunakake minangka casing utawa tubing kanggo sumur

| Standar | sasmita | Komposisi kimia (%) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34-0.39 | 0.20~0.35 | 1.25~1.50 | ≤0,020 | ≤0,015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34-0.38 | 0.20~0.35 | 1.45~1.70 | ≤0,020 | ≤0,015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0,020 | ≤0,010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0,26~0,395 | 0.17~0.37 | 0.40~0.70 | ≤0,020 | ≤0,010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

Sifat Mekanik

| sasmita | Jinis | Total elongation ing beban (%) | kekuatan ngasilake (min) | Kekuwatan ngasilake (maks) | Kekuwatan tarik min Mpa | Kekerasan Maks (HRC) | Kekerasan Max (HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9 Kr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | Kabeh | 0.65 | 862 | 1034 | 931 | - | - |

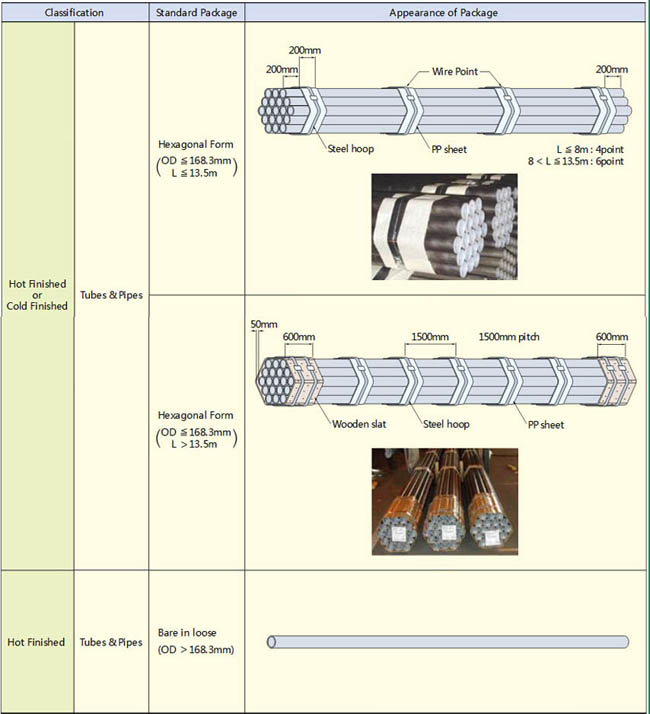

Tunggal karo tas gelembung lan banjur ing kasus kayu (sertifikat fumigasi).Saben kasus diwenehi tandha kanthi cetha:

1. Jeneng & tandha identifikasi produsen-Merek HuaDong

2. Nomer batch

3. Tanggal produsen

4. Materi

5. Aman dadi panas & suhu aplikasi