Pipa paduan nikel

| Bahan | Monel / Inconel / Hastelloy / Duplex Steel / PH Steel / Paduan Nikel |

| wangun | Bulat, Forging, Ring, Coil, Flange, Disc, Foil, Bulat, Pita, Kotak, Bar, Pipa, Lembar |

| sasmita | N02200,N02201,N04400,N06600,N06601,N06625,N06690,N08810,N08825,N08020,N180280,N180280 665,N06022,N06030,GH3030,GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel 617 Inconel601 Inconel691 NS1NS311431 NS112, Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4 Monel K500, N05500 |

| Spesifikasi | Liyane: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 etc |

| Paduan:paduan 625,Paduan 20/28/31 | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001, Hastelloy B-2 / UNS N10665 / DIN W. Nr.2.4617, Hastelloy C, Hastelloy C-4 / UNS N06455 / DIN W. Nr.2.4610, Hastelloy C-22 / UNS N06022 / DIN W. Nr.2.4602, Hastelloy C-276 / UNS N10276 / DIN W. Nr.2.4819, Hastelloy X / UNS N06002 / DIN W. Nr.2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Seri Inconel:Inconel 600/601/602CA/617/625/690/713/718/738/X-750, Tukang Kayu 20; | |

| Inconel 718 / UNS N07718 /N04400/N06600/N08825/DIN W. Nr.2.4668, Inconel 601 / UNS N06601 / DIN W. Nr.2.4851, Inconel 625 / UNS N06625 / DIN W. Nr.2.4856, Inconel 725 / UNS N07725, Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669, Inconel 600 / UNS N06600 / DIN W. Nr.2.4816 | |

| Incoloy:Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132, GH3030, GH3039, GH3128, GH4180, GH3044 | |

| Monel:Monel 400/K500/R405 | |

| Nitronik: Nitronik 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Kawat: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm; Dawane 2000-5000mm Pipa: φ6-273mm;δ1-30mm;Length 1000-8000mm Lembar: δ 0.8-36mm; Jembaré 650-2000mm; Dawane 800-4500mm | |

| produk Karakteristik | 1. Miturut proses preparation bisa dipérang dadi superalloys deformasi, casting superalloys lan wêdakakêna metallurgy superalloys. 2. Miturut mode penguatan, ana jinis penguatan solusi padhet, udan jinis penguatan, jinis penguatan dispersi oksida lan jinis penguatan serat, lsp. |

| Standar | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspeksi | ISO, SGS, BV, lan liya-liyane. |

| Aplikasi | Komponen suhu dhuwur kayata bilah turbin, baling-baling panuntun, disk turbin, tekanan dhuwur disk kompresor, manufaktur mesin lan kamar pembakaran digunakake ing Pabrik aviation, angkatan laut lan turbin gas industri |

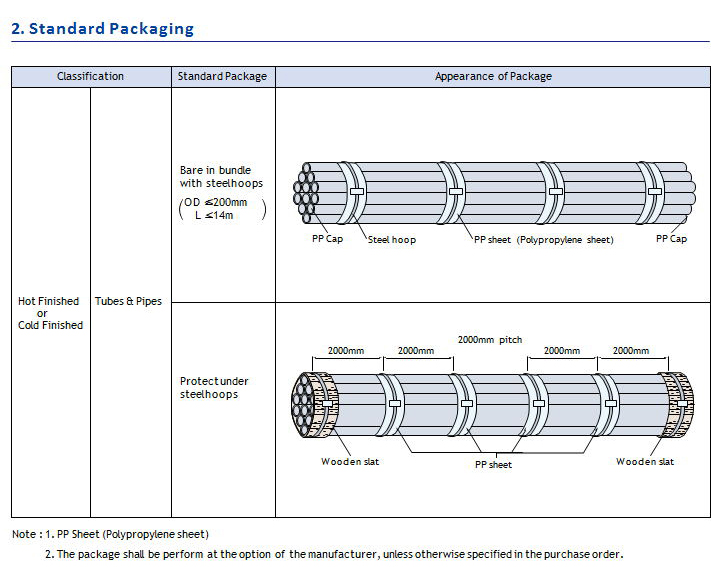

| Kemasan | 1. kasus dikempalken ing kasus kayu 2. kemasan kertas 3. packing plastik 4. kemasan busa Packaging miturut syarat pelanggan utawa produk |

| Pangiriman | 7-25 dina utawa miturut produk |

| pambayaran | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Pembayaran miturut syarat pelanggan kanggo pesenan offline. |

| UKURAN STOCKED | |||||||||||||

| UKURAN | NIKEL | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | UKURAN | |

| 1/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 1,65 mm | |

| 0.010 | X | X | .25 mm | ||||||||||

| 0.020 | X | .51 mm | |||||||||||

| 1/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 3,18 mm | |

| 0.010 | X | 0.25 | |||||||||||

| 0.012 | X | 3,05 mm | |||||||||||

| 0.016 | X | .31 mm | |||||||||||

| 0.020 | X | X | X | .51 mm | |||||||||

| 0,028 | X | X | X | X | .71 mm | ||||||||

| 0.035 | X | X | X | X | .89 mm | ||||||||

| 3/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 4,76 mm | |

| 0.010 | X | .25 mm | |||||||||||

| 0.016 | X | X | .31 mm | ||||||||||

| 0.020 | X | .51 mm | |||||||||||

| 0,028 | X | X | X | .71 mm | |||||||||

| 0.035 | X | X | X | X | X | X | .89 mm | ||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 6,35 mm | |

| 0.016 | X | .31 mm | |||||||||||

| 0.020 | X | X | X | .51 mm | |||||||||

| 0,028 | X | X | X | X | X | .71 mm | |||||||

| 0.035 | X | X | X | X | X | X | X | X | .89 mm | ||||

| 0.049 | X | X | X | X | X | X | X | X | 1,24 mm | ||||

| 0,065 | X | X | X | X | X | X | X | 1,65 mm | |||||

| 0.083 | X | 2,11 mm | |||||||||||

| 5/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 7,94 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0.035 | X | X | X | .89 mm | |||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 3/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 9,53 mm | |

| 0.020 | X | .51 mm | |||||||||||

| 0,028 | X | X | X | X | .71 mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | .89 mm | ||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | 1,65 mm | |||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 7/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 11,1 mm | |

| 0.035 | X | .89 mm | |||||||||||

| 0,065 | X | 1,65 mm | |||||||||||

| 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 12,7 mm | |

| 0,028 | X | X | X | X | .71 mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | X | .89 mm | |||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,058 | X | X | 1,47 mm | ||||||||||

| 0,065 | X | X | X | X | X | X | X | X | 1,65 mm | ||||

| 0.083 | X | X | X | 2,11 mm | |||||||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | 2,77 mm | |||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 9/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 14,3 mm | |

| 0.035 | X | X | X | .89 mm | |||||||||

| 0.049 | X | X | X | X | 1,24 mm | ||||||||

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 0.083 | X | 2,11 mm | |||||||||||

| 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 15,9 mm | |

| 0.035 | X | X | X | X | X | .89 mm | |||||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 3/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 19,1 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0.035 | X | X | X | X | X | X | X | .89 mm | |||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | X | X | X | 1,65 mm | ||

| 0.083 | X | X | X | X | X | X | X | 2,11 mm | |||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | X | X | X | 2,77 mm | ||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 22,2 mm | |

| 0.035 | X | X | X | .89 mm | |||||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 1″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 25,4 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0.035 | X | X | X | X | X | X | .89 mm | ||||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | X | 1,65 mm | ||||

| 0.083 | X | X | X | X | X | X | X | 2,11 mm | |||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | X | X | X | 2,77 mm | ||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.134 | X | X | |||||||||||

| 1 1/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 28,6 mm | |

| 0.049 | X | ||||||||||||

| 1 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 31,8 mm | |

| 0.035 | X | X | X | .89 mm | |||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0.083 | X | X | X | X | 2,11 mm | ||||||||

| 0.095 | X | 2,41 mm | |||||||||||

| 0.109 | X | 2,77 mm | |||||||||||

| 0.120 | X | X | 3,05 mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 38,1 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0.035 | X | X | .89 mm | ||||||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0.083 | X | X | X | 2,11 mm | |||||||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | X | X | 2,77 mm | |||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 5/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 41,3 mm | |

| 0,065 | X | 1,65 mm | |||||||||||

| 0.083 | X | 2,11 mm | |||||||||||

| 1 3/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 44,5 mm | |

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 1 7/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 47,6 mm | |

| 0.083 | X | 2,11 mm | |||||||||||

| 2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 50,8 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0.035 | X | X | .89 mm | ||||||||||

| 0.049 | X | X | 1,24 mm | ||||||||||

| 0,065 | X | X | X | X | X | 1,65 mm | |||||||

| 0.083 | X | X | X | X | 2,11 mm | ||||||||

| 0.095 | X | 2,41 mm | |||||||||||

| 0.109 | X | X | 2,77 mm | ||||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 2 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 57,2 mm | |

| 0.035 | X | .89 mm | |||||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 2 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 63,5 mm | |

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 0.109 | X | 2,77 mm | |||||||||||

| 0.120 | X | X | 3,05 mm | ||||||||||

| 3″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 76,2 mm | |

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0.083 | X | X | X | 2,11 mm | |||||||||

| 0.120 | X | X | 3,05 mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.250 | X | 6.35 | |||||||||||

| 3 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 82,6 mm | |

| 0.125 | X | 3.18 | |||||||||||

| 3 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 88,9 mm | |

| 0.375 | 9,53 mm | ||||||||||||

| Standar | – ASTM A270, ASTM A249, ASTM A511, ASTM A778 , ASTM A312, ASTM A358, ASTM A409, ASTM A213, ASTM A790, ASTM A268, ASTM A269, ASTM A554, ASTM B333, ASTM767, ASTM767, ASTM767 B675, ASTM B676, ASTM B690, ASTM A928, ASME B36.19, ASME B36.10– EN10216-5, EN10217-7, DIN 17456, DIN 17458 – JIS G3463,JIS G3119,JIS G3446,JIS G3218,JIS G3258,JIS G3448,JIS H4631– DEP 31,DEP 40,DEP 20,DEP 32,DNV-OS-F101 |

| Ukuran Range | OD:NPS 1/8 -80, BN 6 – 2000, 10.3 – 2030, kapiler AlaoWT:Sch5s-Sch160s, SchXXH, STD, XS, XXSdawa:Kustomisasi |

| sasmita | S32750, 00Cr25Ni7Mo4N, 022Cr25Ni7Mo4N, 1.441, 1.4307 / 1.4301 / 304L / 3, S30408 / S30403, 0Cr18Ni9DQ, 1.4948 / 30.4948 4948, 06Cr23Ni13, S30908, SUS309S, SUS310S, 1.4845, S31008, S31008S, 06Cr25Ni20, 0Cr25Ni20, 1.4401/1.4404/316/31, S31635, SUS316Ti, 1.4571, 1.4571/316Ti, S31703, 022Cr19Ni13Mo3, 00Cr17Ni12Mo2, S31347, S31703, SUS. 410S, 1.4, 06Cr13, S11306, 0Cr13, S42000, SUS420J1, 1.4021, SUS420J2, 1.4028, S43020, 430F, SUS430F, 1.4104, , 301, 302, 303, 305, 309, 310, 316, 317, 321, 347, 403, 416, 403, 41, 42, 40 07, 304/304L, 304DQ . 0, 630, XM19, C4, S30815 , S31254, 174PH, F51, F60, F53, S32760, 253MA, HC2000, 800H, 926, GH2132, GH4169, GH3030, GH3039, GH4150, GH4150, N0434, N0434, NCMo 08810 |

| ASTM B111 / ASME SB111 | Spesifikasi Standar kanggo Tembaga lan Tembaga-Alloy Seamless Condenser Tubes lan Ferrule Stock | |

| ASTM B161 / ASME SB161 | Spesifikasi Standar kanggo Pipa lan Tabung Nikel Seamless | |

| ASTM B163 / ASME SB163 | Spesifikasi Standar kanggo Kondensor Nikel lan Alloy Nikel lan Tabung Penukar Panas | |

| ASTM B165 / ASME SB165 | Spesifikasi Standar kanggo Paduan Nikel-Tembaga (UNS N04400)* Pipa lan Tabung Seamless | |

| ASTM B167 / ASME SB167 | Spesifikasi Standar kanggo Paduan Nikel-Kromium-Wesi, Paduan Nikel-Kromium-Kobalt-Molibdenum (UNS N06617), lan Paduan Nikel-Wesi-Kromium-Tungsten (UNS N06674) Pipa lan Tabung Seamless | |

| ASTM B395 / ASME SB395 | Spesifikasi Standar kanggo U-Bend Seamless Tembaga lan Tembaga Alloy Heat Exchanger lan Condenser Tubes | |

| ASTM B407 | Spesifikasi Standar kanggo Pipa lan Tube Seamless Alloy Nikel-Wesi-Kromium | |

| ASTM B423 / ASME SB423 | Spesifikasi Standar kanggo Paduan Nikel-Kromium-Molybdenum-Columbium (UNS N06625 lan UNS N06852) lan Paduan Nikel-Kromium-Molibdenum-Silikon (UNS N06219) Pipa lan Tabung | |

| ASTM B444 / ASME SB444 | Spesifikasi Standar kanggo Paduan Nikel-Kromium-Molybdenum-Columbium (UNS N06625 lan UNS N06852) lan Paduan Nikel-Kromium-Molibdenum-Silikon (UNS N06219) Pipa lan Tabung | |

| ASTM B622 / ASME SB622 | Spesifikasi Standar kanggo Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube | |

| ASTM B668 / ASME SB668 | Spesifikasi Standar kanggo UNS N08028 lan N08029 Seamless Pipe and Tube | |

| ASTM B677 / ASME SB677 | Spesifikasi Standar kanggo UNS N08925, UNS N08354, lan UNS N08926 Seamless Pipe and Tube | |

| ASME SB690 / ASME SB690 | Spesifikasi Standar kanggo Paduan Besi-Nikel-Kromium-Molybdenum (UNS N08366 lan UNS N08367) Pipa lan Tabung Seamless | |

| ASTM B705 / ASME SB705 | Spesifikasi Standar kanggo Paduan Nikel (UNS N06625, N06219 lan N08825) Pipa Las | |

| ASTM B729 / ASME SB729 | Spesifikasi standar kanggo UNS N08020, UNS N08026, lan UNS N08024 nikel alloy pipe lan Tube | |

| ASTM B829 / ASME SB829 | Spesifikasi Standar kanggo Requirement Umum kanggo Nikel lan Nikel Alloys Seamless Pipe lan Tube |

Komposisi kimia:

| sasmita | Komposisi kimia | ||||||||

| C | Iki max | Mn maks | P | S | Ni | Cr | Mo | Ti | |

| 200 | 0.15 | 0.35 | 0.35 | 0.010 | 99 min | ||||

| 201 | 0.02 | 0.35 | 0.35 | 0.010 | 99 min | ||||

| 400 | 0.30 | 0.50 | 2.00 | 0,024 | 63 min | ||||

| 600 | 0.15 | 0.50 | 1.00 | 0.015 | 72 min | 14 – 17 | |||

| 601 | 0.10 | 0.50 | 1.00 | 0.015 | 58 – 63 | 21 – 25 | |||

| 625 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 58 min | 20 – 23 | 8 – 10 | 0,40 maks |

| 800 | 0.10 | 1.00 | 1.50 | 0.03 | 0.015 | 30 – 35 | 19 – 23 | 0.15 0.60 | |

| 800H | 0.05 0.10 | 1.00 | 1.50 | 0.015 | 30 – 35 | 19 – 23 | 0.15 0.60 | ||

| 825 | 0.05 | 0.50 | 1.00 | 0.03 | 38 – 46 | 19.5 23.5 | 2.5 3.5 | 0.6 1.2 | |

| 904L | 0.02 | 1.00 | 2.00 | 0.030 | 0.015 | 24 – 26 | 19 23 | 4 5 | |

Sifat Fisik Nikel Alloy

| ALLOY | KEPADATAN ALLOY NICKEL | THERMAL, KONDUKTIVITAS | LINEAR THERMAL, KOEF EXPANSION., (20-95 °C) | RESISTIVITAS ELEKTRIK, PADA 20°C |

| G/CM³ | W/MK | 10-6/K | ΜΩ-CM | |

| NI 200/201 | 8.89 | 70.20 | 13.3 | 9 |

| NI 205/205 LC | 8.89 | 75.00 | 13.3 | 8.9 |