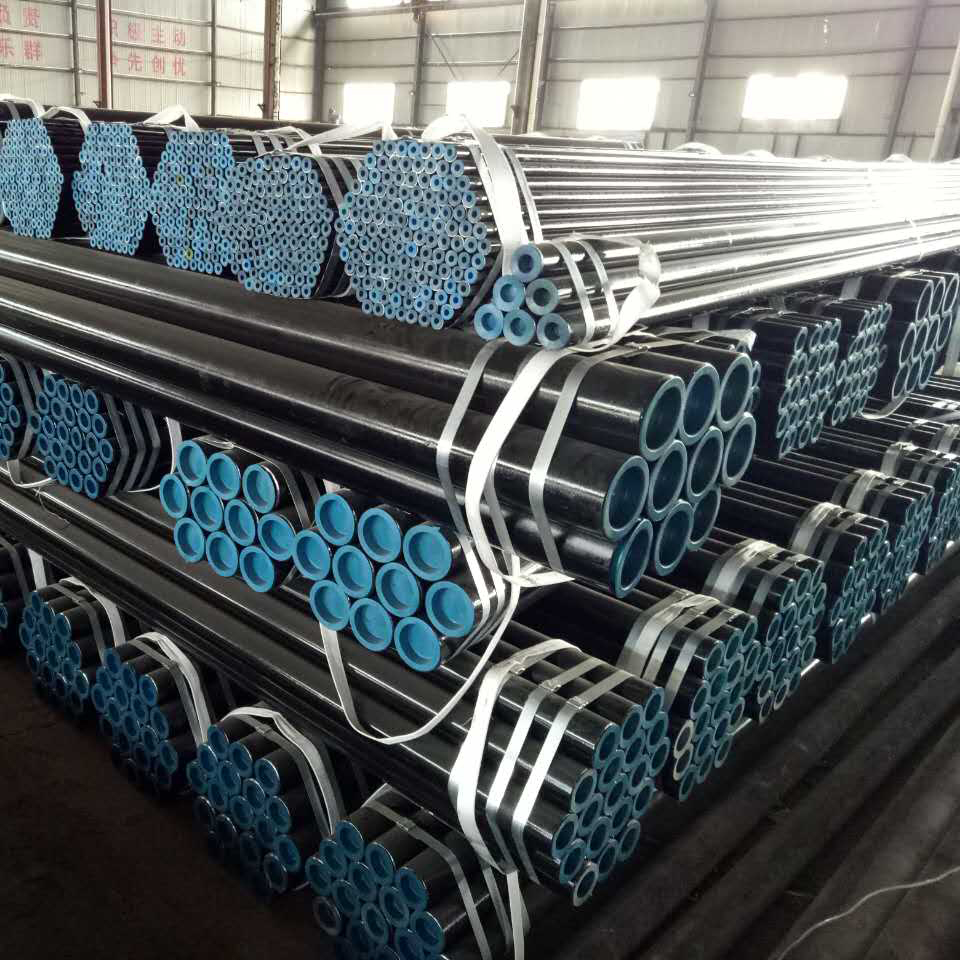

Hot Expanded Seamless Pipe

Pipa baja panas ngembangaken pipa rapi panas ditambahi, kang Kapadhetan relatif kurang nanging kontraksi pipa baja kuwat (pipa rapi) bisa diarani minangka expansion termal.Proses skew rolling utawa cara drawing kanggo nggedhekake diameteripun pipe.Steel pipe thickening ing wektu cendhak wektu, bisa gawé non-standar lan khusus jinis tabung rapi karo kurang-biaya lan efficiency produksi dhuwur, pembangunan internasional saiki ing lapangan rolling tabung.

Pipa nggedhekake panas yaiku kanthi ngembangake diameter pipa kanggo ngrampungake proses - proses ekspansi termal produksi pipa baja.Pipa ekspansi panas biasane diarani pipa baja mulus sing ditambahi panas.

Parameter Teknis Pipa Baja Seamless Hot Expanding:

| Ukuran nominal | Njaba | Ketebalan Dinding Nominal (mm) | |||||||||||||

| DN | NPS | OD(MM) | SCH | SCH | SCH | STD | SCH | SCH | XS | SCH | SCH | SCH | SCH | SCH | XXS |

| 200 250 300 | 8 10 12 | 219.1 273.1 323.9 | 3.76 4.19 4.57 | 6.35 6.35 6.35 | 7.04 7.80 8.38 | 8.18 9.27 9.53 | 8.18 9.27 10.31 | 10.31 12.70 14.27 | 12.70 12.70 12.70 | 12.70 15.09 17.48 | 15.09 18.26 21.44 | 18.26 21.44 25.40 | 20.62 25.40 28.58 | 23.01 28.58 33.32 | 22.23 25.40 25.40 |

| 350 400 450 | 14 16 18 | 355.6 406.4 457.2 | 6.35 6.35 6.35 | 7.92 7.92 7.92 | 9.53 9.53 11.13 | 9.53 9.53 9.53 | 11.13 12.70 14.27 | 15.09 16.66 19.05 | 12.70 12.70 12.70 | 19.05 21.44 23.83 | 23.83 26.19 29.36 | 27.79 30.96 34.93 | 31.75 36.53 39.67 | 35.71 40.49 45.24 | —— |

| 500 550 600 | 20 22 24 | 508 559 610 | 6.35 6.35 6.35 | 9.53 9.53 9.53 | 12.70 12.70 14.27 | 9.53 9.53 9.53 | 15.09 - 17.48 | 20.62 22.23 24.61 | 12.70 | 26.19 28.58 30.96 | 32.54 34.93 38.89 | 38.10 41.28 46.02 | 44.45 47.63 52.37 | 50.01 53.98 59.54 | —— |

| 500 550 600 | 20 22 24 | 508 559 610 | 6.35 6.35 6.35 | 9.53 9.53 9.53 | 12.70 12.70 14.27 | 9.53 9.53 9.53 | 15.09 - 17.48 | 20.62 22.23 24.61 | 12.70 12.70 12.70 | 26.19 28.58 30.96 | 32.54 34.93 38.89 | 38.10 41.28 46.02 | 44.45 47.63 52.37 | 50.01 53.98 59.54 | —— |

| 660 700 750 | 26 28 30 | 660 711 762 | 7.92 7.92 7.92 | 12.70 12.70 12.70 | — 15.88 15.88 | 9.53 9.53 9.53 | —— | —— | 12.70 12.70 12.70 | —— | —— | —— | —— | —— | —— |

| 800 850 900 | 32 34 36 | 813 864 914 | 7.92 7.92 7.92 | 12.70 12.70 12.70 | 15.88 15.88 15.88 | 9.53 9.53 9.53 | 17.48 17.48 19.05 | —— | 12.70 12.70 12.70 | —— | —— | —— | —— | —— | —— |

| Diameter njaba (mm) / | SCH | SCH | SCH | STD | SCH | SCH | XS | SCH | SCH | SCH | SCH | SCH |

| 457 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.88 | 29.36 | 34.93 | 39.67 | 45.24 |

| 508 | 6.35 | 9.53 | 12.70 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 |

| 559 | 6.35 | 9.53 | 12.70 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | |

| 610 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.39 | 46.02 | 52.37 | 59.54 |

| 660 | 7.92 | 12.70 | 9.53 | 12.70 | ||||||||

| 711 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||

| 762 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||

| Cathetan: Standar lan spesifikasi ing ndhuwur mung kanggo referensi, kita uga bisa ngasilake produk sing disesuaikan miturut panjaluk pelanggan. | ||||||||||||

Perawatan lumahing pipa baja:

Supaya kanggo nambah urip layanan saka pipo lenga, perawatan lumahing biasane digawa metu kanggo nggampangake kombinasi tenan saka pipe baja lan lapisan anticorrosive.Cara Processing umum: reresik, alat derusting, pickling, dijupuk blasting derusting papat kategori.

1 cleaningGrease, bledug, lubricant, bahan Organic adhered ing lumahing pipe baja, biasane nggunakake solvent, emulsion kanggo ngresiki surface.Nanging, ing teyeng, kulit oxide lan welding slag ing lumahing pipe baja ora bisa dibusak, supaya liyane cara perawatan needed.Tool teyeng removalSteel pipe lumahing oxide, teyeng, welding slag, bisa nggunakake sikat kawat baja kanggo ngresiki lan polish lumahing treatment.Tool derusting bisa dipérang dadi manual lan daya, alat manual derusting bisa tekan Sa

2 tingkat, alat daya derusting bisa tekan tingkat Sa3. Yen lumahing pipe baja ditempelake karo kulit oxide utamané kuwat, iku uga mokal kanggo mbusak teyeng karo bantuan saka pribadi, supaya kita kudu golek cara liyane.

3 pickling Cara pickling umum kalebu kimia lan electrolysis.Nanging mung pickling kimia digunakake kanggo pipo pangayoman karat.Chemical pickling bisa entuk jurusan tartamtu saka karesikan lan roughness ing lumahing pipe baja, kang trep kanggo garis anchor sakteruse. dijupuk (pasir) sawise reprocessing.

4 shot blasting kanggo mbusak teyengBy motor daya dhuwur drive kacepetan dhuwur puteran glathi, grit baja, dijupuk baja, bagean, mineral lan kabel abrasive liyane ing tumindak pasukan centrifugal ing semprotan lumahing pipa baja lan ejection massa, sak tenane mbusak teyeng, oksida lan rereget ing tangan siji, ing tangan liyane, pipe baja ing tumindak impact kasar abrasive lan pasukan gesekan, kanggo entuk roughness seragam dibutuhake.Antawis papat cara perawatan, dijupuk blasting lan derusting cara perawatan becik kanggo pipe derusting.Umumé, shot blasting lan derusting utamané digunakake kanggo perawatan lumahing utama saka pipe baja, lan dijupuk blasting lan derusting utamané digunakake kanggo perawatan lumahing njaba saka pipe baja.