Pipa Bor Bobot abot

Pipa pengeboran bobot integral integral yaiku zona transisi antarane kerah pengeboran lan pipa pengeboran.Ora mung bisa nyuda formasi kaku ing sambungan krah pengeboran lan pipa pengeboran, nanging uga nyuda nyandhang ing OD.

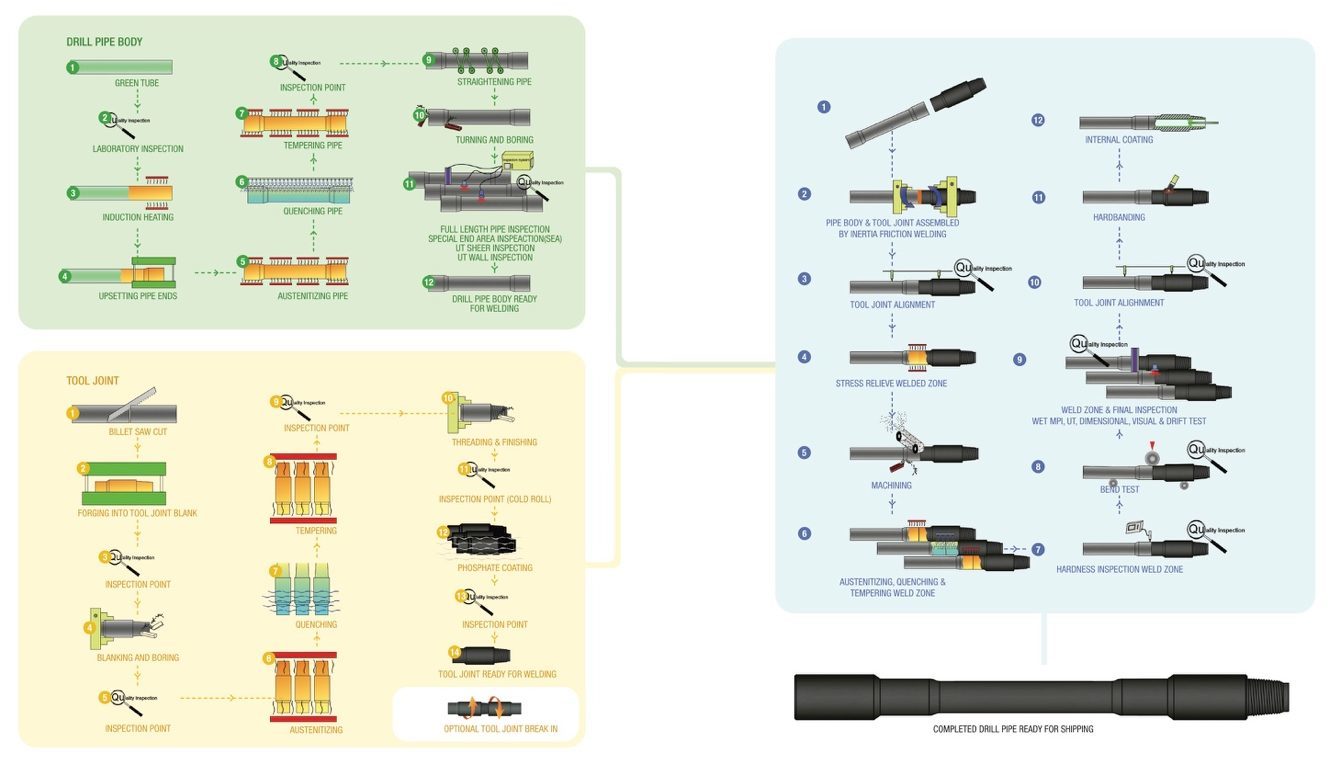

Pipa pengeboran bobot integral integral digawe saka siji potongan bar padat AISI 4145H, diolah kanthi panas, kabeh sifat fisik cocog karo API spec7 edisi paling anyar.

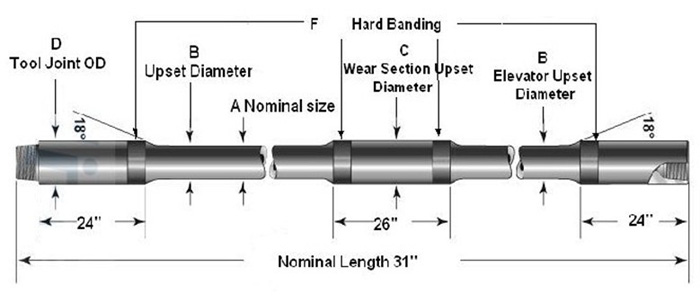

Banding hard resistance HWDP minangka standar ing sambungan sambungan alat lan gangguan tengah.Jinis hard banding kalebu Arnco 100XT lan 100XT.Kabeh Utas wis phosphated, copperized utawa cold worked.Kabeh sambungan dilengkapi pelindung benang baja sing ditekan.Kabeh theads sing machined karo CNC lathes -Double-shoudered lan Utas khusus.

Spesifikasi teknis lan paramèter

| Ukuran (in) | OD (ing) | ID (ing) | Alat Joint OD (ing) | ID Gabungan Alat (ing) | Sambungan | Diameter maksimum lift (ing) | Central upset dia.(ing) | Min. drift dia.size (in) |

| 3 1/2 | 3 1/2 | 2 1/4 | 4 3/4 | 2 1/4 | NC38 | 3 7/8 | 4 | 2 |

| 2 1/16 | 2 1/16 | 1 13/16 | ||||||

| 4 | 4 | 2 1/2 | 5 1/4 | 2 1/2 | NC40 | 4 3/16 | 4 1/2 | 2 1/4 |

| 2 9/16 | 2 9/16 | 2 5/16 | ||||||

| 4 1/2 | 4 1/2 | 2 11/16 | 6 1/4 | 2 11/16 | NC46 | 4 11/16 | 5 | 2 7/16 |

| 2 3/4 | 2 3/4 | 2 1/2 | ||||||

| 2 13/16 | 2 13/16 | 2 9/16 | ||||||

| 5 | 5 | 3 | 6 5/8 | 3 | NC50 | 5 1/8 | 5 1/2 | 2 3/4 |

| 5 1/2 | 5 1/2 | 3 1/4 | 7 | 3 1/4 | 5 1/2 FH | 5 11/16 | 6 | 3 |

| 3 3/8 | 3 3/8 | 3 1/8 | ||||||

| 3 7/8 | 3 7/8 | 3 5/8 | ||||||

| 4 | 4 | 3 3/4 | ||||||

| 6 5/8 | 6 5/8 | 4 | 8 | 4 | 6 5/8 FH | 6 15/16 | 7 1/8 | 3 3/4 |

| 4 1/2 | 4 1/2 | 4 1/4 | ||||||

| 5 | 5 | 4 3/4 |

| Pipa bor berat spiral | ||||||||

| Spesifikasi mm | tabung | gabungan | ||||||

| ID mm | Lift ngamuk | alur elevator / Slip njaba diametermm | Screw ing diameter mm | Kedalaman alur spiral mm | Tipe Utas | OD mm | ID mm | |

| 88.9(3 1/2) | 54 | 92.1 | 88.9 | 101.6 | 9.5 | NC38 | 120.6 | 54 |

| 114.3(4 1/2) | 69.8 | 117.5 | 114.3 | 127 | 12.7 | NC46 | 158.8 | 69.8 |

| 127.0(5) | 76.2 | 130.2 | 127 | 139.7 | 12.7 | NC50 | 165.1 | 76.2 |

| Steel Mark | Komposisi kimia% | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Al | |

| 4145H | 0.42~0.48 | 0.15~0.35 | 0.90~1.20 | ≤0.03 | ≤0.03 | 0.90~1.20 | 0.15~0.25 | ≤0.2 | 0,025~0.045 |

| Unsur liyane:N≤0,015,Ni≤0.5 | |||||||||

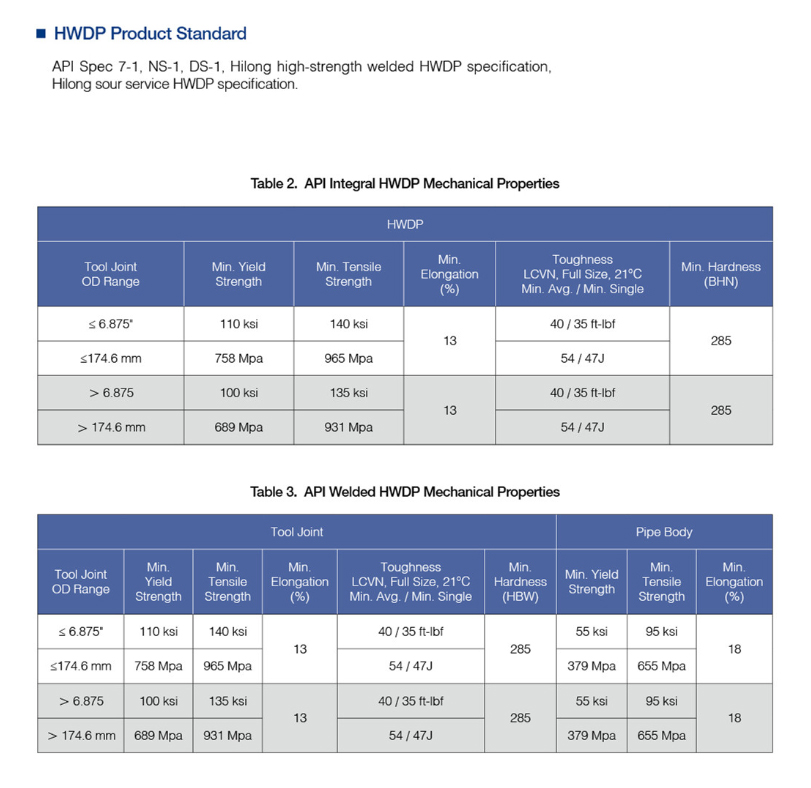

| Aplikasi | Bahan | Ukuran | Kekuatan Hasil (Min KSI) | Ultimate Strength (Min KSI) | Kekerasan Brinell (HB) | Elongasi (A%) | Min Charpy (ft-lbs @+20°C) |

| Standar Integral | AISI 4145H dipunéwahi | Kabeh | 110 | 140 | 285 kanggo 340 | 13 | 40 |

| Standar Welded | AISI 1340 Diowahi | Kabeh | 65 | 95 | 235 (maks) | 18 | 30 |

| Las NS-1 | AISI 4140H dipunéwahi | Kabeh | 120 | 140 | 285 kanggo 340 | 13 | 40 |

| Standar Welded | AISI 4140H dipunéwahi | Ndhuwur 7 1/4" | 120 | 140 | 285 kanggo 340 | 13 | 40 |

| Standar dilas | AISI 4140H dipunéwahi | Nganti 7 1/4" | 100 | 135 | 285 kanggo 340 | 13 | 40 |

| HWDP-110 HW MS | ASCOWELL C | Ndhuwur 6 3/4" | 110 | 140 | 285 kanggo 340 | 13 | 0 |

| HWDP-110 HW MS | ASCOWELL C | Nganti 6 3/4" | 100 | 135 | 285 kanggo 340 | 13 | 55 |

| HWDP-65 HW MS (tool joint) | ASCOWELL C | Ndhuwur 6 3/4" | 110 | 140 | 285 kanggo 340 | 13 | 55 |

| HWDP-65 HW MS (tool joint) | ASCOWELL C | Nganti 6 3/4" | 100 | 135 | 285 kanggo 340 | 13 | 55 |

| HWDP-65 HW MS | AISI 1340 Diowahi | Kabeh | 65 | 95 | 235 (maks) | 18 | 30 |