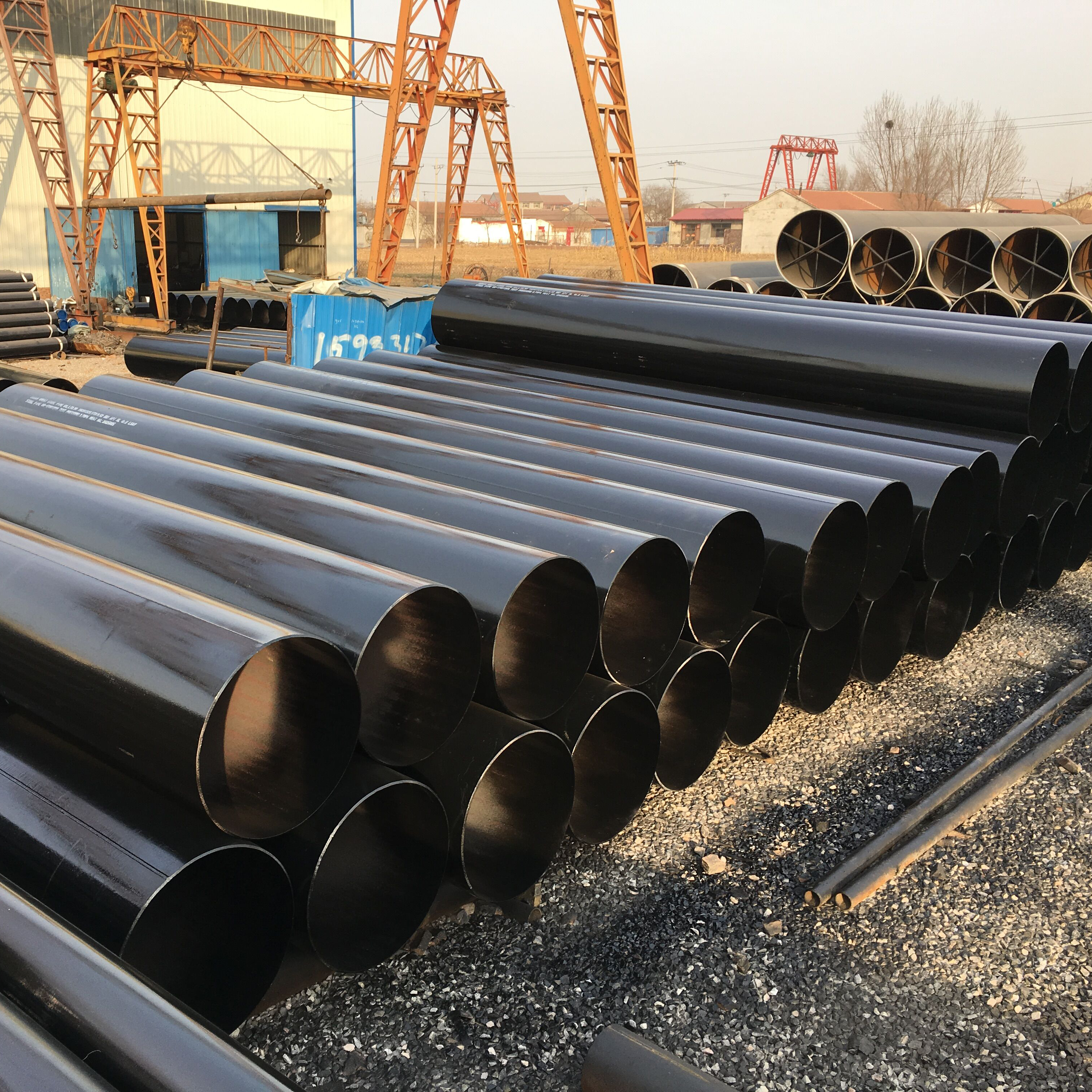

Pipa Baja LSAW

Pipa Baja LSAW ( Longitudinal Seam Submerged Arc Welding Pipe )

Pipa BAJA UOE LSAW

Pabrik UOE nduweni teknologi lan proses sing paling maju, entuk efisiensi produksi sing dhuwur, kualitas produk sing stabil lan dilengkapi peralatan inspeksi lengkap.pabrik UOE adopts U & O mbentuk, pipo kawangun sing gandheng nang liwat limang stasiun welding internal karo telung kabel, lan gandheng njaba liwat papat stasiun welding external karo telung kabel.Sesuai karo syarat sing beda saka pelanggan, pipe gandheng bisa ditambahi salah siji mechanical utawa hydrostatic nggedhekake kanggo nambah akurasi dimensi, lan ngilangke kaku ampas.

Spesifikasi

Dhiameter njaba 508mm- 1118mm (20"- 44")

Ketebalan Dinding: 6.0-25.4mm 1/4"-1"

Standar Kualitas: API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Dawane: 9-12.3m (30'- 40')

Kelas: API 5L A-X90,GB/T9711 L190-L625

PIPA JOCE LSAW(PRES BENDING)

Iki gedhe diameteripun longitudinal submerged busur gandheng (LSAW) pipe line produksi ing China.Pabrik nganggo proses mlengkung progresif, nampilake stres mbentuk sing disebarake kanthi rata, ukuran seragam sing dhuwur, variasi ukuran tanpa wates & sawetara prouct sudhut, lan keluwesan sing dhuwur, lsp.

Spesifikasi

Diameter njaba: Φ406mm- 1626mm (16" - 64")

Kekandelan tembok:6.0-75mm (1/4" - 3")

Standar Mutu:API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

dawa:3-12.5m ( 10'- 41' )

biji:API 5L A-X100, GB/T9711 L190-L690

Ukuran Pipa Baja LSAW

| Diameter metu | Ketebalan tembok (mm) | ||||||||||||||||

| inch | mm | 6.4 | 7.1 | 7.9 | 9.53 | 12.7 | 14.3 | 15.9 | 19.1 | 22.2 | 25.4 | 28.6 | 31.8 | 34.9 | 38.1 | 41.3 | 44.5 |

| 16 | 406.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 22 | 559 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 24 | 610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 26 | 660 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 28 | 711 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 30 | 762 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 32 | 813 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 34 | 864 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 36 | 914 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 38 | 965 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 40 | 1016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 42 | 1067 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 44 | 1118 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 46 | 1168 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 48 | 1219 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 52 | 1321 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 56 | 1422 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 60 | 1524 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 64 | 1626 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Toleransi Diameter njaba lan Kekandelan Tembok

| Jinis | Standar | |||||

| SY/T5040-2000 | SY/T5037-2000 | SY / T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

| Tabung end OD deviasi | ± 0,5% D | ± 0,5% D | -0,79 mm~+2,38 mm | <± 0,1% T | <± 0,1% T | ± 1,6 mm |

| Ketebalan tembok | ± 10,0% T | D<508mm, ± 12,5% T | -8%T~+19,5% T | <-12,5% T | -8%T~+19,5% T | 5,0 mm |

| D> 508mm, ± 10,0% T | T≥15.0mm, ±1.5mm | |||||

Komposisi Kimia lan Sifat Mekanik

| Standar | sasmita | Komposisi kimia (maks)% | Sifat Mekanik (min) | |||||

| C | Mn | Si | S | P | Kekuwatan Ngasilake (Mpa) | Kekuwatan Tarik (Mpa) | ||

| GB / T700-2006 | A | 0.22 | 1.4 | 0.35 | 0,050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB / T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS En10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0,050 | 0,050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0,050 | 0,050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0,050 | 0,050 | 235 | 400 |

| SS490 | - | - | - | 0,050 | 0,050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Dilenga entheng, Hot dip galvanis, Electro galvanis, Ireng, Bare, Lapisan pernis/minyak anti karat, Lapisan Pelindung