Pipa Baja Karbon Seamless

Pipa Baja Seamless digawe saka baja bunder sing padhet'billet'kang digawe panas lan di-push utawa ditarik liwat wangun nganti baja wis shaped menyang tabung kothong.Pipa lancar banjur rampung kanggo spesifikasi dimensi lan kekandelan tembok kanthi ukuran saka 1/8 inci nganti 32 inci OD.Carbon Steel Seamless Pipe / Tubes Baja karbon minangka paduan sing kasusun saka wesi lan karbon.Persentase karbon ing baja mengaruhi kekerasan, kekuatan elastisitas lan daktilitas baja karbon.pipa baja karbon rapi utawa ingot baja ngalangi digawe saka tabung kapiler liwat bolongan, banjur liwat panas-mbalek, kadhemen mbalek utawa telpon kadhemen digawe.Pipa baja karbon mulus ing industri baja China nduweni posisi penting.Bahan pipa baja karbon sing mulus yaiku tabung bunder, embrio mesin pemotong pipa kanggo nglereni babagan 1 m dawane kosong, lan dikirim kanthi pemanasan tungku sabuk conveyor.Billet dilebokake ing tungku pemanasan, suhu kira-kira 1200 derajat Celsius.Bahan bakar yaiku hidrogen utawa asetilena.Kontrol suhu tungku minangka masalah utama.Tabung bunder metu kanggo ngetokake mesin liwat tekanan udara.Umume pukulan sing luwih umum yaiku mesin perforasi roll tapered, efisiensi produksi sing dhuwur, kualitas produk, ekspansi bolongan diameter gedhe, bisa nganggo macem-macem baja.Perforation, tabung babak wis ing telung muter salib rolling, rolling utawa extrusion.Diremet saka tabung sawise ukuran.Sizing dening kacepetan dhuwur rotary conthong pengeboran bolongan menyang billet kanggo mbentuk tabung.Dhiameter pipa dening pabrik ukuran kanggo nemtokake dawa diameter pengeboran.Sawise pipa liwat ukuran menyang menara cooling, cooling dening semprotan banyu, baja sawise cooling, kudu straightening.Sawise sabuk baja dikirim dening straightening mesin testing logam (utawa test meksa) kanggo testing internal.Yen pipa internal retak, gelembung lan masalah liyane bakal dideteksi.Sawise pipa nanging uga liwat pilihan manual kontrol kualitas sing ketat.Kualitas baja, panggunaan nomer cat semprot, spesifikasi, nomer lot produksi.Kanthi crane menyang gudang.

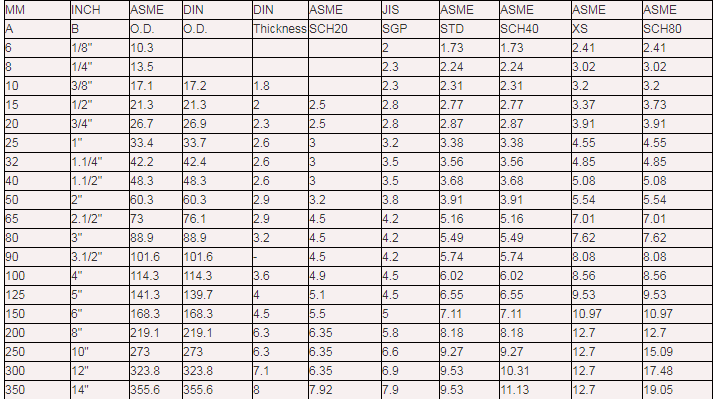

Kekandelan tembok pipa sing mulus

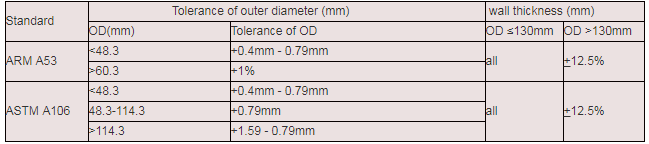

Toleransi saka diameteripun njaba lan kekandelan tembok

| Standar | Katrangan |

| ASTM A179/A179M | Seamless kadhemen digambar penukar panas baja paduan rendah lan tabung kondensor. |

| API 5L | Pipa garis. |

| ASTM A53M | Black & Zinc Coated Welded lan Seamless Steel Pipe. |

| ASTM A106M | Pipa baja karbon mulus kanggo layanan suhu dhuwur. |

| ASTM A105M | Tempa baja karbon kanggo aplikasi pipa. |

| ASTM A234M | Fitting pipa saka baja karbon tempa lan baja paduan kanggo layanan suhu moderat lan dhuwur. |

| ASTM 3799 | Pipa baja fitting, ngaco lan weldability soket kanggo industri petroleum. |

| AS 1163 | Bagian hollow baja struktural |

| AS 1074 | Tabung baja lan tubular kanggo layanan biasa |

| BS13872 | Screwed lan socketed tabung baja lan tubulars |

| Standar | Jinis pipa | kelas | sasmita |

| API SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q, L485Q X70Q

| ||

| PLS2 Lingkungan Asem | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| WELD | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Standar | sasmita |

| ASTM A 53 M | A, B |

| ASTM A 106M | A, B, C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

kelas: Komposisi Kimia (%):

| Standar | sasmita | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0,25 | - | ≤0,95 | ≤0.05 | ≤0,045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0,045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A 106M | A | ≤0,25 | ≥0.10 | 0.27-0.93 | ≤0,035 | ≤0,035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0,035 | ≤0,035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0,035 | ≤0,035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G 3454 | STPG 370 | ≤0,25 | ≤0.35 | 0.30-0.90 | ≤0,040 | ≤0,040 | - | - | - | - | - |

| STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0,040 | ≤0,040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0,25 | 0.10-0.35 | 0.30-1.10 | ≤0,035 | ≤0,035 | - | - | - | - | - |

| STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0,035 | ≤0,035 | - | - | - | - | - | |

| STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0,035 | ≤0,035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0,25 | 0.10-0.35 | 0.30-0.90 | ≤0,035 | ≤0,035 | - | - | - | - | - |

| STPT 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0,035 | ≤0,035 | - | - | - | - | - | |

| STPT 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0,035 | ≤0,035 | - | - | - | - | - |

perawatan lumahing saka pipe baja: Supaya kanggo nambah urip layanan saka pipo lenga, perawatan lumahing biasane digawa metu kanggo nggampangake kombinasi tenan saka pipe baja lan coating anticorrosive.Cara Processing umum yaiku: reresik, alat derusting, pickling, dijupuk blasting derusting. papat kategori.1 cleaningGrease, bledug, lubricant, bahan Organic adhered ing lumahing pipe baja, biasane nggunakake solvent, emulsion kanggo ngresiki surface.Nanging, ing teyeng, kulit oxide lan welding slag ing lumahing pipe baja ora bisa dibusak, supaya liyane cara perawatan needed.Tool teyeng removalSteel pipe lumahing oxide, teyeng, welding slag, bisa nggunakake sikat kawat baja kanggo ngresiki lan polish lumahing treatment.Tool derusting bisa dipérang dadi manual lan daya, alat manual derusting bisa tekan Sa 2 tingkat, daya alat derusting bisa tekan tingkat Sa3. Yen lumahing pipe baja ditempelake karo kulit oxide utamané kuwat, iku uga mokal kanggo mbusak teyeng karo bantuan saka pribadi, supaya kita kudu golek cara liyane.3 pickling Cara pickling umum kalebu kimia lan electrolysis.Nanging mung pickling kimia digunakake kanggo pipo pangayoman karat.Chemical pickling bisa entuk jurusan tartamtu saka karesikan lan roughness ing lumahing pipe baja, kang trep kanggo garis anchor sakteruse. dijupuk (pasir) sawise reprocessing.4 shot blasting kanggo mbusak teyengBy motor daya dhuwur drive kacepetan dhuwur puteran glathi, grit baja, dijupuk baja, bagean, mineral lan kabel abrasive liyane ing tumindak pasukan centrifugal ing semprotan lumahing pipa baja lan ejection massa, sak tenane mbusak teyeng, oksida lan rereget ing tangan siji, ing tangan liyane, pipe baja ing tumindak impact kasar abrasive lan pasukan gesekan, kanggo entuk roughness seragam dibutuhake.Antawis papat cara perawatan, dijupuk blasting lan derusting cara perawatan becik kanggo pipe derusting.Umumé, shot blasting lan derusting utamané digunakake kanggo perawatan lumahing utama saka pipe baja, lan dijupuk blasting lan derusting utamané digunakake kanggo perawatan lumahing njaba saka pipe baja.

Semprotan cat

Semprotan cat

Kemasan anti banyu