Pipa Baja Struktural

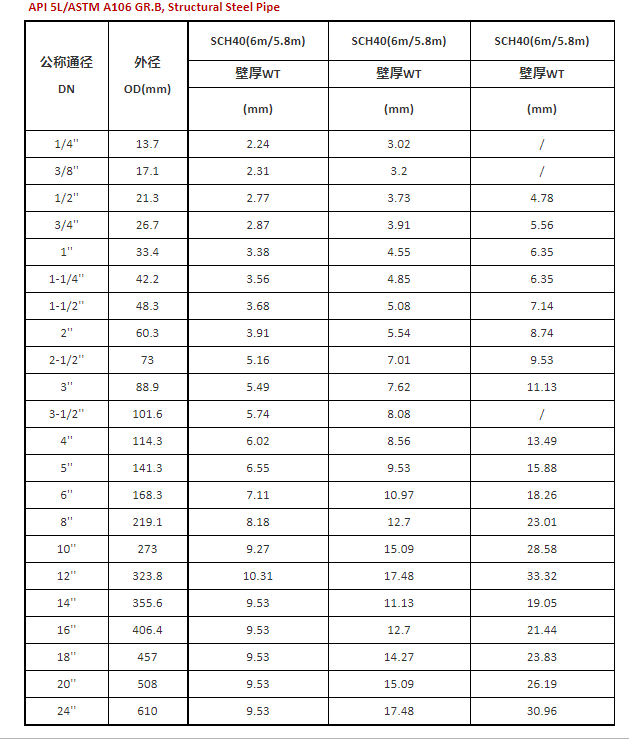

Pipa baja struktur wis panas - mbalek tabung baja rapi lan tabung baja gandheng.Tabung baja rapi kanggo struktur dipérang dadi rong jinis miturut pranata "tabung baja rapi kanggo struktur" (GB/ t8162-2008): rolling panas ( extrusion, expansion) lan drawing kadhemen (rolling) .Diameter njaba saka pipe baja panas-mbalek punika 32-630mm lan kekandelan tembok 2.5-75mm.Dhiameter njaba pipa baja sing ditarik kadhemen yaiku 5-200mm lan kekandelan tembok yaiku 2.5-12mm.Pipa baja gandheng digawe saka piring baja utawa Strip baja sawise crimping lan mbentuk, kang bisa dipérang dadi pipe baja gandheng sakcara lan spiral pipe baja gandheng. Dhiameter njaba lan kekandelan tembok saka pipe baja langsung gandheng 5-508mm lan 0,5 -12.7mm mungguh, kang bakal tundhuk karo pranata GB / t3793-2008. Pipa baja gandheng kanggo transportasi adi meksa kurang uga disebut pipe gandheng umum, umum dikenal minangka pipe clark.Spesifikasi kasebut ditulis ing mm diameter nominal, sing kudu tundhuk karo pranata GB / t3091-2008 kanggo transportasi cairan tekanan rendah.

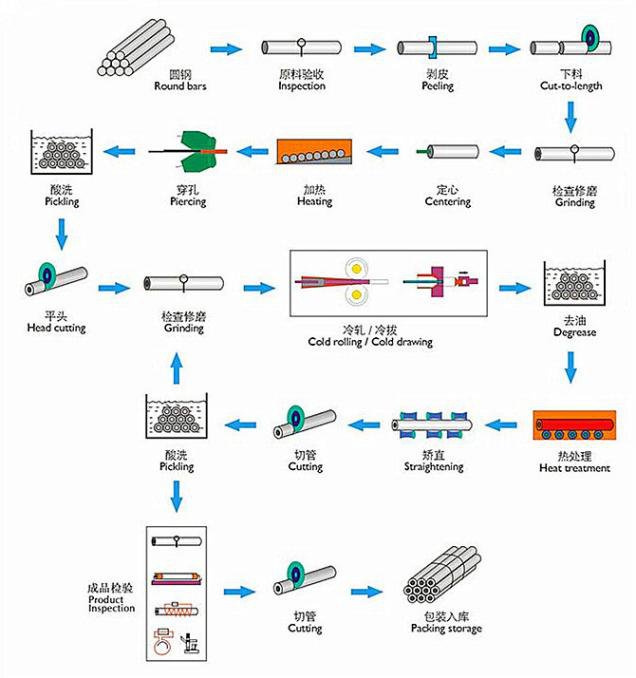

Proses Manufaktur

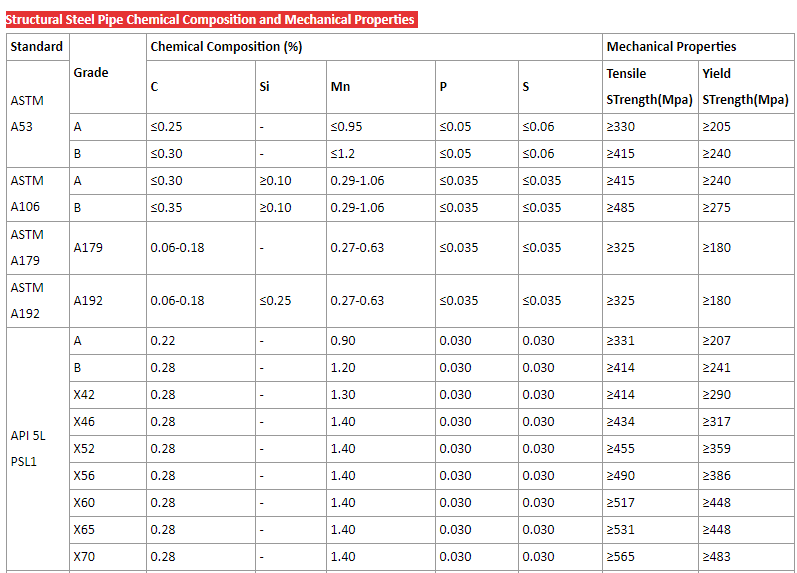

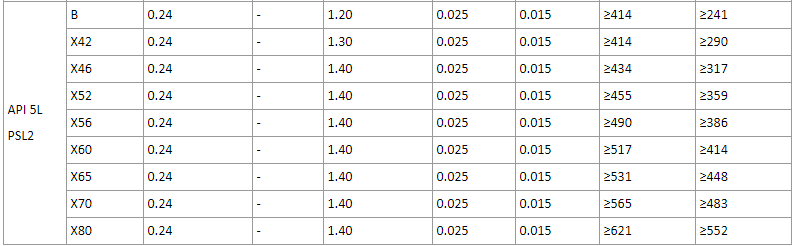

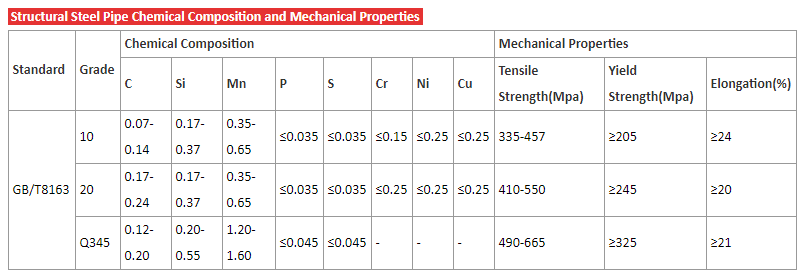

Komposisi kimia

| sasmita | C | Mn | P | S | Si | Cr | Mo |

| 1010 | 0.08-0.13 | 0.30-0.60 | ≤0.04 | ≤0.05 | - | - | - |

| 1020 | 0.08-0.23 | 0.30-0.60 | ≤0.04 | ≤0.05 | - | - | - |

| 1045 | 0.43-0.50 | 0.60-0.90 | ≤0.04 | ≤0.05 | - | - | - |

| 4130 | 0.28-0.33 | 0.40-0.60 | ≤0.04 | ≤0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.75-1.00 | ≤0.04 | ≤0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

Sifat Mekanik

| sasmita | kahanan | Kekuatan tarik Mpa (min) | Kekuwatan ngasilake Mpa (min) | Elongation% (min) |

| 1020 | CW | 414 | 483 | 5 |

| SR | 345 | 448 | 10 | |

| A | 193 | 331 | 30 | |

| N | 234 | 379 | 22 | |

| 1025 | CW | 448 | 517 | 5 |

| SR | 379 | 483 | 8 | |

| A | 207 | 365 | 25 | |

| N | 248 | 379 | 22 | |

| 4130 | SR | 586 | 724 | 10 |

| A | 379 | 517 | 30 | |

| N | 414 | 621 | 20 | |

| 4140 | SR | 689 | 855 | 10 |

| A | 414 | 552 | 25 | |

| N | 621 | 855 | 20 |

Annealed, Normalized, Stress lega, Dingin rampung, Quenched lan Tempered