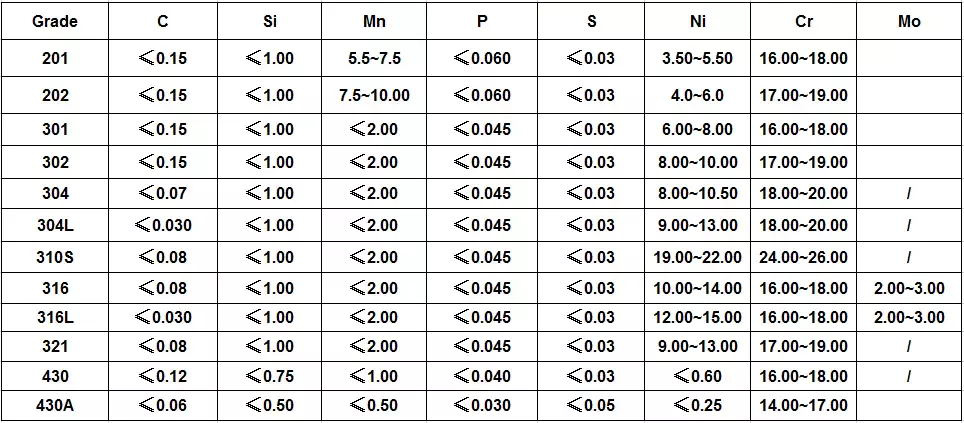

Plat baja tahan karat

Lembaran baja tahan karat 310/310S

310 stainless steel austenitic kromium nikel stainless steel wis resistance oksidasi apik, resistance karat, amarga persentasi luwih saka kromium lan nikel, 310 wis kekuatan creep luwih apik, bisa terus-terusan ing suhu dhuwur, resistance panas apik.

310S stainless steel punika austenitic kromium nikel stainless steel, wis apik 310S stainless steel resistance oksidasi, resistance Corrosive.

Bedane komposisi kimia kanggo baja tahan karat 310/310S

| sasmita | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | N(%) | Cu(%) |

| 310 | ≤0,25 | ≤1.0 | ≤2.0 | ≤0.03 | --- | 24.0-26.0 | 19.0-22.0 | --- | --- |

| 310S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.03 | ≤0.03 | 24.0-26.0 | 19.0-22.0 | --- | --- |

Bedane sifat mekanik kanggo stainless steel 310/310S

| sasmita | kekuatan tarikMpa | Kekuwatan NgasilakeMpa | Elongation(%) | tingkat pangurangan ing wilayah(%) | Kapadhetan(g/cm3) |

| 310 | ≥470 | ≥17 | ≥40 | ≥50 | 7.98 |

| 310S | ≥520 | ≥205 | ≥40 | ≥50 | 7.98 |

Lembaran tahan karat 304/304L/304H

Babagan 304 materi:304 stainless steel minangka bahan stainless steel umum, Kapadhetan 7,93 g / cm3, industri uga disebut 18/8 stainless steel.Resistance suhu dhuwur 800 derajat, kanthi kinerja pangolahan sing apik, karakteristik ketangguhan sing dhuwur, akeh digunakake ing industri dekorasi industri lan perabotan lan industri panganan.

Babagan materi 304L:304L baja minangka C kurang ing negara umum, resistance karat lan 304 padha, nanging sawise welding utawa kaku sawise resistance karat banget kanggo wates gandum.Ing kasus tanpa perawatan panas, bisa tetep resistance karat apik, umume nggunakake 400 utawa kurang (non-Magnetik, suhu -196 derajat Celsius kanggo 800 derajat Celsius).Digunakake kanggo ngasilake syarat kinerja sakabèhé sing apik (resistensi karat lan bisa dibentuk) saka peralatan lan bagean.

Babagan materi 304H:304H minangka jinis baja tahan karat, kanthi lentur sing apik, kinerja proses las, tahan korosi, daya tahan dhuwur lan stabilitas organisasi, kemampuan deformasi kadhemen apik banget.Suhu paling dhuwur bisa tekan 650 DEG C, lan resistance oksidasi nganti 850 DEG C

Bedane komposisi kimia kanggo 304 304L 304H

| sasmita | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | N(%) | |

| 304 | ≤0.08 | ≤0,75 | ≤2.0 | ≤0,045 | ≤0.03 | 18.0-20.0 | 8.0-10.5 | ≤0.1 | |

| 304L | ≤0.03 | ≤0,75 | ≤2.0 | ≤0,045 | ≤0.03 | 18.0-20.0 | 8.0-12.0 | ≤0.1 | |

| 304H | 0.04-1.0 | ≤0,75 | ≤2.0 | ≤0,045 | ≤0.03 | 18.0-20.0 | 8.0-10.5 | ---- | |

Bedane sifat Mekanik kanggo 304 304L 304H

| sasmita | kekuatan tarik(Mpa) | Kekuwatan Ngasilake(Mpa) | Elongation(%) | Kekerasan(HR) |

| 304 | ≥515 | ≥205 | ≥40 | ≥92 |

| 304L | ≥485 | ≥170 | ≥40 | ≥92 |

| 304H | ≥515 | ≥205 | ≥40 | ≥92 |

316/316L lembaran baja tahan karat

Babagan 316 materi:316 stainless steel kanthi nambah unsur Mo, resistance karat, lan kekuatan suhu dhuwur wis nemen apik, suhu dhuwur bisa tekan 1200-1300 derajat, bisa digunakake ing kahanan abot. resistance Corrosion luwih saka 304 stainless steel, ing pulp lan kertas produksi proses wis resistance karat apik.Lan 316 stainless steel uga tahan kanggo erosi saka segara lan atmosfer industri korosif.

Babagan materi 316L:316L stainless steel nduweni isi karbon kurang saka 316, kang umume digunakake ing pulp lan kertas exchanger panas peralatan, peralatan dyeing, peralatan ngumbah film, pipelines, wilayah pesisir njaba bahan bangunan.Resistance korosi luwih apik tinimbang materi 316.

Bedane komposisi kimia kanggo baja tahan karat 316 316L

| sasmita | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | Cu(%) |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,045 | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,045 | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

Bedane sifat mekanik kanggo baja tahan karat 316 316L

| sasmita | kekuatan tarikMpa | Kekuwatan NgasilakeMpa | Elongation(%) | tingkat pangurangan ing wilayah(%) | Kapadhetan(g/cm3) |

| 316 | ≥520 | ≥205 | ≥40 | ≥60 | 7.98 |

| 316L | ≥480 | ≥177 | ≥40 | ≥60 | 7.98 |

430 lembaran baja tahan karat

430 stainless steel punika resistance karat apik saka baja umum, kinerja termal saka austenitic apik, koefisien expansion termal saka austenitic cilik, lemes panas, nambah unsur stabil titanium, bagean weld kinerja mechanical apik.

Baja tahan karat 430 digunakake ing panggunaan arsitektur, bagean pembakar bahan bakar, peralatan rumah tangga, bagean peralatan omah.

Komposisi kimia kanggo 430 stainless steel

| sasmita | C(%) | Mn(%) | Si(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | Cu(%) |

| 430 | ≤0.12 | ≤1.0 | ≤0,75 | ≤0.04 | ≤0.03 | 16.0-18.0 | ≤0.06 | --- | --- |

Properti mekanik kanggo 430 stainless steel

| sasmita | kekuatan tarikMpa | Kekuwatan NgasilakeMpa | Elongation(%) | tingkat pangurangan ing wilayah(%) | Kapadhetan(g/cm3) |

| 430 | ≥450 | ≥205 | ≥22 | --- | 7.75 |

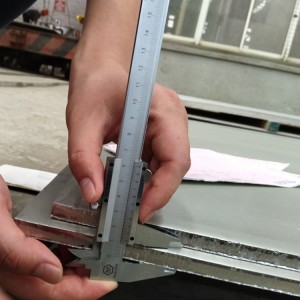

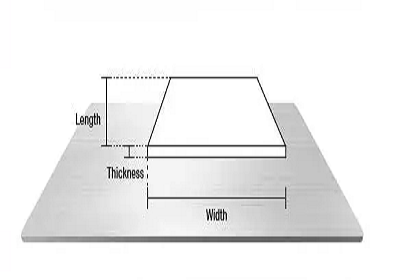

| sasmita | Rampung | Ketebalan (mm) | Jembar (mm) | Dawane (mm) |

| 310 | 2B / No.4 / HL / BA / Pangilon lsp | 0.4mm-0.3mm | Jembar standar ing China: 1000mm 1219mm 1500mm | |

| 310s | No.1 | 3.0mm-80.0mm | Jembar standar ing China: 1219mm 1500mm 2000mm | |

| 304 | 2B, No.4 PE | 0.55 | 914, 1219 | 1828, 2438 |

| 304 | 2B, No. 4 PE | 0.70 | 914, 1219 | 1828, 2438 |

| 304 | 2B, 2B PE, No. 4 PE, BA PE | 0.90 | 914, 1219 | 1828, 2438 |

| 304 | 2B, 2B PE, No. 4 PE, BA PE | 1.20 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No. 4 PE | 1.50 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No. 4 PE | 1.60 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No. 4 PE | 2.00 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No. 4 PE | 2.50 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No. 4 PE | 3.00 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304L | 2B, 2B PE | 4.00 | 1500, 2000 | 3000, 6000 |

| 304H | 2B / No.4 / HL / BA / Mirror etcNo.1 | 3.00 | 1219, 1500,2000 | |

| 310 | 2B / No.4 / HL / BA / | 0.4-0.3 | 1000,1219,1500 | |

| 310s | No.1 | 3.00 | 1219, 1500,2000 | |

| 316 | 2B | 0.55 | 1219 | 2438 |

| 316 | 2B | 0.70 | 1219 | 2438 |

| 316 | 2B | 0.90 | 1219 | 2438 |

| 316 | 2B, No.4 PE | 1.20 | 1219 | 2438 |

| 316 | 2B, No.4 PE | 1.50 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B, No.4 PE | 1.60 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B, No.4 PE | 2.00 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B, No.4 PE | 2.50 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B, No.4 PE | 3.00 | 1219, 1500 | 2438, 3000, 3658 |

| 316L | 2B, 2B PE | 4.00 | 1500, 2000 | 3000, 6000 |

| 430 | BA PE, No. 4 PE | 0.70 | 914, 1219 | 1828, 2438 |

| 430 | BA PE, No. 4 PE | 0.90 | 914, 1219 | 1828, 2438 |

| 3CR12 | 2B | 1.2 | 1250 | 2500 |

| 3CR12 | 2B | 1.6 | 1250 | 2500 |

| 3CR12 | 2B | 2.0 | 1250 | 2500 |

| 3CR12 | No. 1 | 4.0 | 1250, 1500 | 2500, 3000, 6000 |

Tingkat lan jembar liyane

Kelas: 301L, 310, 321, 2205, 253MA.

Jembar (mm): 600, 750, 900, 1050, 1200, 1524.

Lembaran baja tahan karat 310/310S

| sasmita | GB / T 1220-2007 | ASTM | DIN | JIS | KS |

| 310 | 20Cr25Ni20 | 310 | 1.4821 | SUS310 | STS310 |

| 310S | 06Cr25Ni20 | 310S | 1.4845 | SUS310S | STS310S |

Standar kanggo 304 304L 304H stainless steel

| sasmita | GB / T 1220-2007 | ASTM | DIN | JIS | KS |

| 304 | 06Cr19Ni10 | 304 | 1.4301 | SUS304 | STS304 |

| 304L | 022Cr19Ni10 | 304L | 1.4306 | SUS304L | STS304L |

| 304H | —- | 304H | —- | SUS304H | STS304H |

Standar kanggo 316/316L stainless steel

| sasmita | GB / T 1220-2007 | ASTM | DIN | JIS | KS |

| 316 | 06Cr17Ni12Mo2 | 316 | 1.4401 | SUS316 | STS316 |

| 316L | 022Cr17Ni12Mo | 316L | 1.4404 | SUS316L | STS316L |

Standar kanggo430baja tahan karat

| sasmita | GB | ASTM | DIN | JIS |

| 316 | 10Cr17 | 430 | 1.4016 | SUS430 |

| kekandelan | Massa nominal Austenitik (kg/m²) | Massa nominal feritik (kg/m²) |

| 0.45 | 3.68 | |

| 0.55 | 4.50 | |

| 0.70 | 5.72 | |

| 0.90 | 7.36 | |

| 1.20 | 9.81 | 9.61 |

| 1.50 | 12.3 | |

| 1.60 | 13.08 | 12.85 |

| 2.00 | 16.35 | 16.02 |

| 2.50 | 20.44 | 20.03 |

| 3.00 | 24.53 | 24.04 |

| 4.00 | 32.71 | 32.06 |

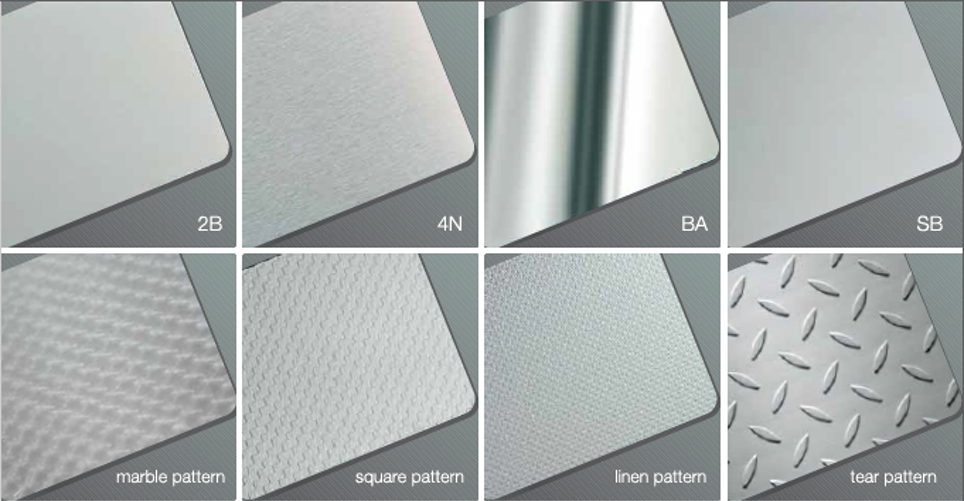

| Lumahing Rampung | definisi | Aplikasi |

| 2B | Sing rampung, sawise rolling kadhemen, dening perawatan panas, pickling utawa perawatan padha lan pungkasan dening kadhemen Rolling kanggo diwenehi luster cocok. | Peralatan medis, Industri Pangan, Bahan Konstruksi, Peralatan Dapur. |

| BA | Sing diproses kanthi perawatan panas sing padhang sawise rolling kadhemen. | Peralatan Pawon, Peralatan Listrik, Konstruksi Bangunan. |

| NO.3 | Sing rampung dening polishing karo No.100 kanggo No.120 abrasives kasebut ing JIS R6001. | Peralatan pawon, Konstruksi Bangunan. |

| NO.4 | Sing rampung dening polishing karo No.150 kanggo No.180 abrasives kasebut ing JIS R6001. | Peralatan Pawon, Konstruksi Bangunan, Peralatan Medis. |

| HL | Sing rampung polishing supaya menehi garis polishing terus-terusan kanthi nggunakake abrasive ukuran gandum cocok. | Konstruksi Bangunan. |

| NO.1 | Lumahing rampung dening perawatan panas lan pickling utawa pangolahan cocog ana sawise rolling panas. | Tangki kimia, pipa. |

| No.8 | Rampung 'pangilon' kanthi reflektif.Diprodhuksi saka finish 2B kanthi polishing kanthi abrasive sing luwih apik kanthi berturut-turut kanthi buffing ekstensif.Utamane digunakake ing aplikasi arsitektur. | |

| Khusus pelanggan | Rampung 'pangilon' kanthi reflektif.Diprodhuksi saka finish 2B kanthi polishing kanthi abrasive sing luwih apik kanthi berturut-turut kanthi buffing ekstensif.Utamane digunakake ing aplikasi arsitektur. |