Pipa Baja ERW

(1) pipe gandheng saka welding piring baja menyang pipe babak, dipérang dadi resistance frekuensi dhuwur gandheng pipe (RW welded pipe), jahitan terus busur welding pipe (LSAW), spiral gandheng pipe.Electrical engineering karo "SC", bisa digunakake minangka pipa gas banyu uga bisa digunakake minangka pipa threading, relatif kandel.

(2) Pipeline pipe, uga dikenal minangka pipa kabel, relatif tipis, dilambangake dening "T", lan mung bisa digunakake kanggo threading.ERW steel pipeERW steel pipe

(3) ERW tabung punika "frekuensi dhuwur resistance welding tabung baja", lan proses welding umum beda, baris weld saka bahan dasar saka awak sabuk baja ilang, kekuatan mechanical luwih saka welding.ERW umum stands kanggo welding resistance, welding resistance nduweni karakteristik efisiensi produksi sing dhuwur, biaya sing murah, ngirit materi lan otomasi sing gampang, saengga akeh digunakake ing penerbangan, aeroangkasa, energi, elektronik, otomotif, industri ringan lan sektor industri liyane, minangka salah sawijining proses welding penting.

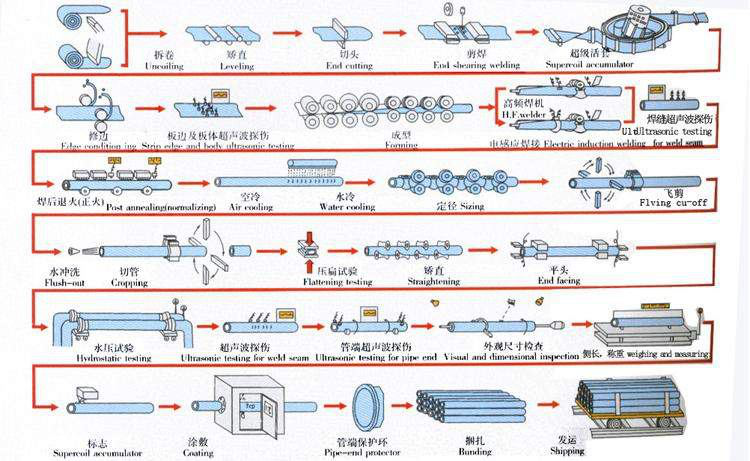

Proses produksi pipa baja ERW:

Uncoiling --- 2. Leveling --- 3. End cutting --- 4. End shearing welding --- 5. Supercoil accumulator --- 6. Edge cutting --- 7. Ultrasonic detection --- 8. Forming - -- 9. Welding induksi listrik --- 10. Deteksi ultrasonik kanggo jahitan las --- 11. Perlakuan panas frekuensi medium --- 12. Pendinginan udara --- 13. Pendinginan banyu --- 14. Ukuran --- 15 Pemotongan terbang --- 16. Flush-out --- 17. Cropping --- 18. Pengujian flattening --- 19. Straightening --- 20. End facing and bevelling --- 21. Pengujian hidrodinamik --- 22 . Deteksi ultrasonik kanggo jahitan las --- 23. Deteksi ultrasonik kanggo ujung pipa --- 24. Pemeriksaan visual lan dimensi --- 25. Bobot lan pangukuran --- 26. Penandaan --- 27. Pelapisan --- 28. Proteksi pipa-mburi --- 29. Mlengkung --- 30. Pengiriman

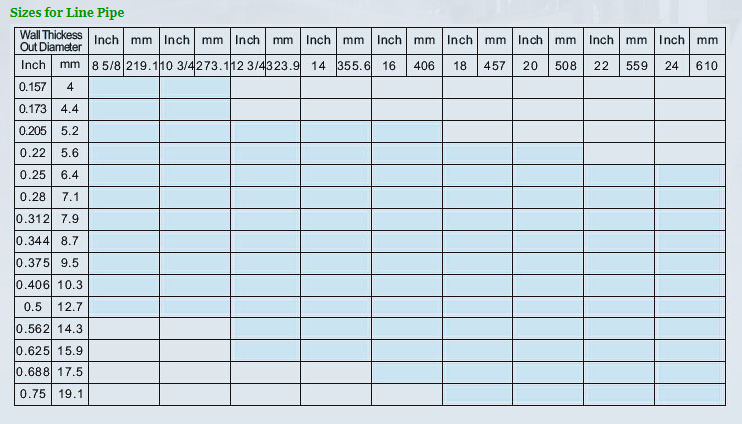

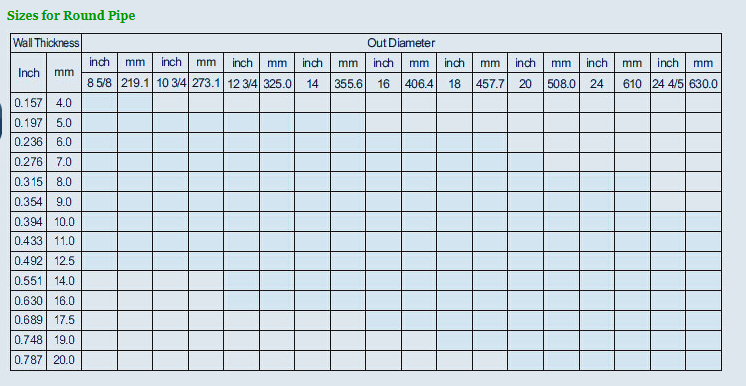

Ukuran, Spesifikasi, Ukuran Pipa Baja ERW

| OD | WT | |||||||||||||||||||||||||

| inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | |

| 0.157 | 4 | 0.173 | 4.4 | 0.205 | 5.2 | 0.22 | 5.6 | 0.25 | 6.4 | 0.28 | 7.1 | 0.312 | 7.9 | 0.344 | 8.7 | 0.375 | 9.5 | 0.406 | 10.3 | 0.5 | 12.7 | 0.562 | 14.3 | |||

| 8 5/8 | 219.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10 3/4 | 273.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 12 3/4 | 323.9 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 14 | 355.6 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 16 | 406 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10022 | 559 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 241 | 610 |

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

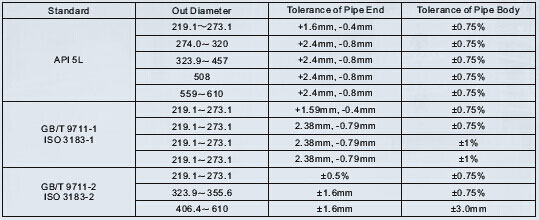

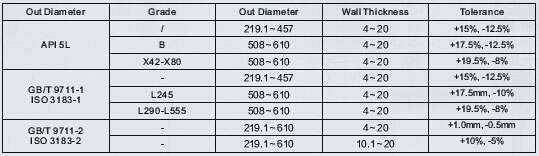

Toleransi Diameter njaba - Pipa Baja ERW

Toleransi Kekandelan Tembok - Pipa Baja ERW

Dilenga entheng, Hot dip galvanis, Electro galvanis, Ireng, Bare, Lapisan pernis/minyak anti karat, Lapisan Pelindung