Kawat Titanium / Sutra

Kita bisa nyedhiyakake kabel tantalum saka leleh balok elektron vakum lan teknologi metalurgi bubuk, tujuan umum kabel tantalum diprodhuksi dening teknologi leleh sinar elektron vakum, nduweni kemurnian sing relatif dhuwur.Kabel tantalum kelas kapasitor biasane diprodhuksi dening teknologi metalurgi bubuk, ngemot unsur logam sing luwih khusus.Kawat tantalum diprodhuksi kanthi basis tantalum bar.pisanan kabeh, Rolling metu ukuran cocok saka tantalum bar, reresik bar tantalum, kanggo mbusak majalah lumahing lan polusi lenga, trimming bar tantalum lan resik maneh, banjur liwat mulet lan annealing kanggo kaping pirang-pirang, pungkasanipun njaluk specifications saka syarat customer , liwat reresik, straightening, nduwurke tumpukan, kita bisa njaluk kabel lurus utawa kumparan.Giant Metal cara unik rolling, proses mulet, kontrol rasio komprèsi, suhu annealing lan kontrol wektu annealing bisa njamin kabel tantalum duwe mechanical banget, nggawe lumahing Gamelan, resik, ora lenga, ora ana retak lan burrs, ora kekacoan watara, lan diamati ing 25 kaping magnification, wis ora dents terus-terusan lan goresan, duwe struktur metallurgical apik, supaya minangka kanggo mesthekake kualitas kabel tantalum luwih saka perusahaan liyane ing industri padha.

Saliyane nyedhiyakake kawat tantalum murni, perusahaan kita uga nyedhiyakake kawat paduan tantalum.

Bahan:

Kawat Tantalum Niobium (TaNb3, TaNb20, TaNb40)

Kawat Tungsten Tantalum (Ta2.5W, Ta10W)

Dhiameter: 0.1 ~ 4mm

Standar: ASTM B365

Wangun: Lurus, Coil

Status: Hard, Semi-hard, entheng

Aplikasi

Kabel tantalum kelas kapasitor utamane digunakake kanggo nggawe timbal anoda kapasitor elektrolitik tantalum.kabel tantalum minangka bahan kunci kanggo kapasitor tantalum, kapasitor tantalum minangka kapasitor paling apik, kira-kira 65% tantalum ing donya digunakake ing lapangan iki.

Digunakake kanggo ngasilake bolong tantalum.

Digunakake kanggo jahitan kanggo ngimbangi jaringan otot, jahitan saraf lan tendon, produksi stent pembuluh getih, lsp.

Digunakake kanggo ngasilake komponen pemanasan tungku suhu dhuwur vakum.

Digunakake kanggo vakum elektron emitting sumber cathode, ion sputtering lan bahan lapisan, etc.

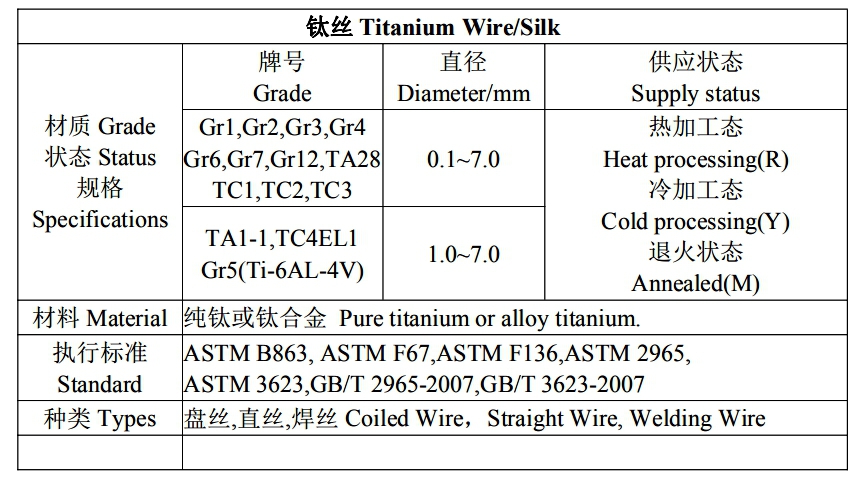

| Titanium Wire Dhiameter lan Jinis | ||||

| Dhiameter & Jinis | ||||

| Dhiameter Range | Jinis | |||

| mm | inch | Koil | Spool | Lurus |

| 0,05 kanggo 0,78 | 0,002 kanggo 0,031 | Y | Y | N |

| > 0,78 kanggo 3,25 | > 0,031 kanggo 0,128 | Y | Y | Y |

| > 3.25 kanggo 6.00 | > 0,128 kanggo 0,236 | Y | N | Y |

Toleransi Diameter: +/- 0,05mm (+/- 0,002") utawa luwih alus.Spools: 100mm - 300mm (3.9 "-12").Dawane Lurus: 300mm - 3000mm (12" - 118")

| sasmita | Spesifikasi | ||

| AWS A5.16 | ASTM B863 | AMS | |

| Titanium murni komersial | ERTi-1,2,3,4 | ASTM B863 Gr1,2,3,4 | AMS 4951 |

| ASTM F67 Gr1,2,3,4 | AMS 4921 | ||

| Ti 6Al-4V | ERTi-5 | ASTM B863 Gr5 | AMS 4954 |

| Ti 6Al-4V Eli | ERTi-5 Eli | ASTM B863 Gr23 | AMS 4956 |

| ASTM F136 Eli | |||

| Ti 0.2 Pd | ERTi-7 | ASTM B863 Gr7 | – |

| Ti 3Al-2.5V | ERTi-9 | ASTM B863 Gr9 | – |

| Ti 0.3Mo-0.8Ni | ERTi-12 | ASTM B863 Gr12 | – |

Komposisi kimia

| Komposisi (%) | |||||||||||||

| sasmita | Unsur utama | Konten pengotor (≤) | |||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | |

| Ta1 | Bal | — | 0.005 | 0.005 | 0.002 | 0.01 | 0.01 | 0.002 | 0.03 | 0.015 | 0.01 | 0,0015 | 0.005 |

| Ta2 | Bal | — | 0.03 | 0.02 | 0.005 | 0.04 | 0.03 | 0.005 | 0.1 | 0.02 | 0.01 | 0,0015 | 0.005 |

| TaNb3 | Bal | 1.5~3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | — | 0.02 | 0.01 | 0.005 | 0.01 |

| TaNb20 | Bal | 17.0-23.0 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | — | 0.02 | 0.01 | 0.005 | 0.01 |

| TaNb40 | Bal | 35.0~42.0 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | — | 0.02 | 0.01 | 0.015 | 0.01 |

| Ta2.5W | Bal | — | 0.01 | 0.005 | 0.01 | 2.0 ~ 3.5 | 0.01 | 0.002 | 0.1 | 0.01 | 0.01 | 0,0015 | 0.01 |

| Ta10W | Bal | — | 0.01 | 0.005 | 0.01 | 9.0 ~ 11.0 | 0.01 | 0.002 | 0.1 | 0.015 | 0.01 | 0,0015 | 0. |

Sifat mekanik

| Status | Kekuatan tarik (Mp) | Elongation (%) |

| entheng | 300-750 | 10~30 |

| Semi-hard | 750-1250 | 1~6 |

| Hard | > 1250 | 1~5 |

| TaNb3, TaNb20, sifat mekanik miturut pabrik diukur. | ||

Toleransi (mm)

| Dhiameter | Toleransi |

| 0.1~0.2 | < 0,005 |

| 0.2~0.5 | < 0,007 |

| 0.5-0.7 | < 0,010 |

| 0.7-1.5 | < 0,015 |

| 1.5~2.0 | < 0,020 |

| 2.0~3.0 | < 0,030 |

| 3.0-4.0 | < 0,040 |

Antioksidan brittleness

| sasmita | Diameter (mm) | Antioksidan brittleness Jumlah lentur (≥) |

| Ta1 | 0.10~0.40 | 3 |

| > 0.40 | 4 | |

| Ta2 | 0.10~0.40 | 4 |

| > 0.40 | 6 |

Kabel coil: Sawise angin lan bingkisan karo katun mutiara (poliethelin expandable), banjur dikempalken ing kasus kayu.

Kawat lurus: Bungkus kawat tantalum ing kantong plastik lan lebokake tong plastik lurus, banjur dibungkus ing kasus kayu.