Ring Titanium Kab

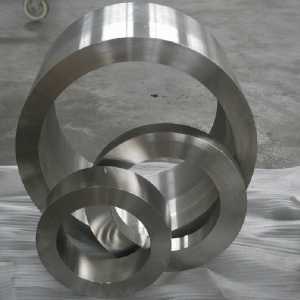

Dering titanium gedhe diprodhuksi dening mesin ring grinding gedhe, dering titanium cilik bisa digayuh kanthi mesin tempa.Minangka perusahaan sing duwe pengalaman produksi luwih saka 20 taun, kita duwe seri proses penempaan sing ketat lan manual operasi, kalebu langkah-langkah pemanasan, wektu pemanasan lan wektu pengawetan panas.Mesin tempa cepet 35MN lan 16MN njamin pirang-pirang tempa ing sawetara suhu sing cocog, lan ngganti struktur fisik internal cincin titanium.Apik banget kualitas produk kita.

Saliyane ring titanium, kita uga nyedhiyakake produksi cakram titanium, blok titanium lsp.

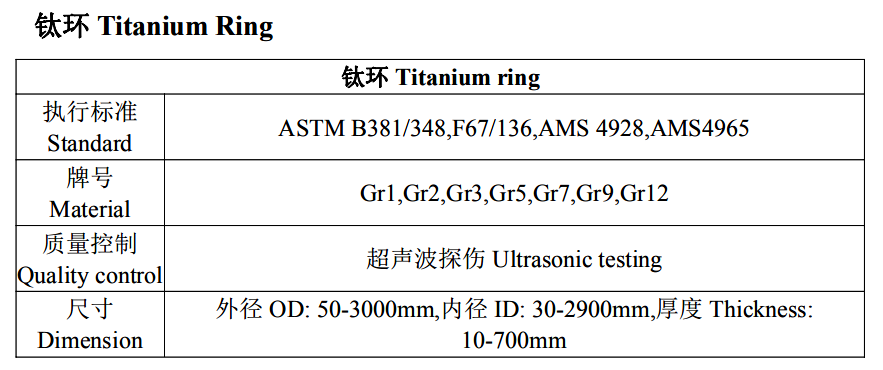

| jeneng produk | Ring Titanium Kab |

| Ukuran | OD (maks. 3000mm)×ID (maks. 2900mm)×dawa (dawa maksimum 1000mm) |

| sasmita | TA1/TA2/TA5/TA6/TA9/TA10/TA15/TA19/TC1/TC2/TC4/TC11/ GR1/GR2/GR5/GR7/GR9/GR12/GR23 |

| Standar | ASTM B381/348, F67/136, AMS4928, AMS4965,AMS,MIL,DIN,BS,JIS,GB / T,ISOlsp |

| Kapadhetan | 4.51g / cm3 Tempa industri kinerja dhuwur, gr12 Titanium ring rolling palsu |

| Teknologi | Forging, rolling, grinding kinerja dhuwur industri forging GR12 titanium forging ring rolling |

| Jinis | Proses rolling dering sing mulus kalebu nglereni bolongan ing bahan palsu lan digulung dadi cincin tipis. Dibandhingake karo tembak piring utawa welding butt, dering palsu sing digulung nyedhiyakake perbaikan konsentris kanthi dering permukaan sing mulus. Ring kinerja dhuwur industri palsu GR12 titanium ring rolling palsu |

| Aplikasi | 1. Electroplating;2.Teknologi kimia lan petrokimia;3.Medical kinerja dhuwur industri forging GR12 titanium forging rolling ring |

ASTM B381/348, F67/136, AMS4928, AMS4965

Komposisi kimia

| sasmita | Komposisi kimia, persen bobot (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Unsur liyane Maks.saben | Unsur liyane Maks.gunggung | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | 0.12~0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6-0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04-0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.1 |

Sifat fisik

| sasmita | Sifat fisik | |||||

| Kekuwatan tensile Min | kekuatan ngasilaken Min (0,2%, offset) | Elongation ing 4D Min (%) | Pengurangan Area Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |