I-Titanium Ring

Amasongo amakhulu e-titanium akhiqizwa umshini omkhulu wokugaya, izindandatho ezincane ze-titanium zingafinyelelwa ngomshini wokwenza.Njengenkampani eneminyaka engaphezu kwengu-20 yokuhlangenwe nakho kokukhiqiza, sinochungechunge lwenqubo eqinile yokuqamba kanye nebhukwana lokusebenza, okuhlanganisa izinyathelo zokushisa, isikhathi sokushisa kanye nesikhathi sokugcina ukushisa.Umshini wokubumba osheshayo ongu-35MN kanye no-16MN uqinisekise ukufoja okuningi ebangeni lokushisa elifanele, futhi washintsha isakhiwo sangaphakathi somzimba sezindandatho ze-titanium.Ithuthukise kakhulu ikhwalithi yemikhiqizo yethu.

Ngaphezu kwendandatho ye-titanium, siphinde sinikeze ukukhiqizwa kwe-titanium disc, i-titanium block njll.

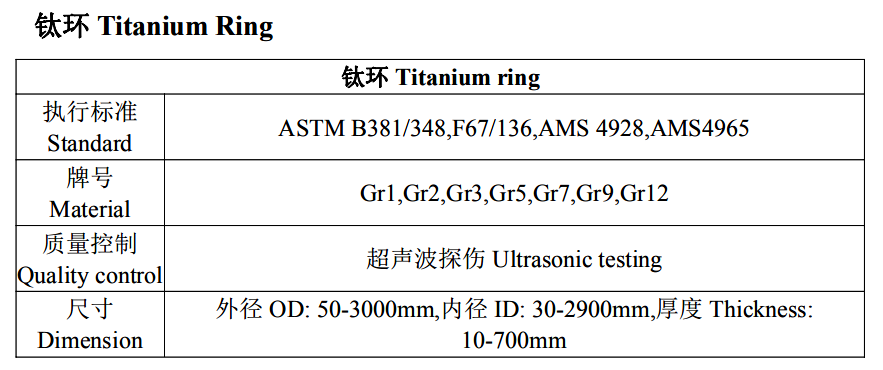

| igama lomkhiqizo | I-Titanium Ring |

| Usayizi | OD (max3000mm)×I-ID (max2900mm)×ubude (ubude obukhulu 1000mm) |

| Ibanga | TA1/TA2/TA5/TA6/TA9/TA10/TA15/TA19/TC1/TC2/TC4/TC11/ GR1/GR2/GR5/GR7/GR9/GR12/GR23 |

| Amazinga | ASTM B381/348,F67/136,AMS4928,AMS4965,I-AMS,I-MIL,I-DIN,BS,I-JIS,I-GB / T,ISOnjll |

| Ukuminyana | 4.51g / cm3 Ukusebenza okuphezulu kwe-industrial forging, i-gr12 Titanium forged rolling ring |

| Ubuchwepheshe | Ukuqamba, ukugingqa, ukugaya ukusebenza okuphezulu kwezimboni zokubumba i-GR12 titanium forging rolling ring |

| Uhlobo | Inqubo yokugingqa indandatho engenamthungo ihlanganisa ukusika imbobo ezintweni ezibunjiwe bese uyigoqa ibe yindandatho encane. Uma kuqhathaniswa nokudubula kwepuleti noma ukushisela izinqe, indandatho egoqwe yomgunyathi inikeza ukuthuthuka okugxilile ngendandatho yangaphezulu ebushelelezi. Iringithoni esebenza kahle kakhulu eyenziwe ngezimboni i-GR12 titanium eguquguqukayo |

| Isicelo | 1. I-Electroplating;2.Ubuchwepheshe bamakhemikhali kanye ne-petrochemical;3.Ukusebenza kwezokwelapha okusezingeni eliphezulu kwemboni ye-GR12 titanium forging rolling ring |

ASTM B381/348,F67/136,AMS4928,AMS4965

Ukwakheka kwamakhemikhali

| Ibanga | Ukwakheka kwamakhemikhali, iphesenti lesisindo (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ezinye Izinto Ubukhulu.ngamunye | Ezinye Izinto Ubukhulu.ingqikithi | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5-4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12-0.25 | - | 0.12-0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5-3.5 | 2.0-3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12-0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6-0.9 | 0.2-0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04–0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5-6.5 | 3.5-4.5 | - | - | - | - | 0.1 | 0.1 |

Izici ezingokomzimba

| Ibanga | Izici ezingokomzimba | |||||

| Amandla aqinile Okuncane | Amandla esivuno Ubuncane (0.2%, i-offset) | I-Elongation ku-4D Ubuncane (%) | Ukuncishiswa Kwendawo Ubuncane (%) | |||

| ksi | I-MPa | ksi | I-MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |