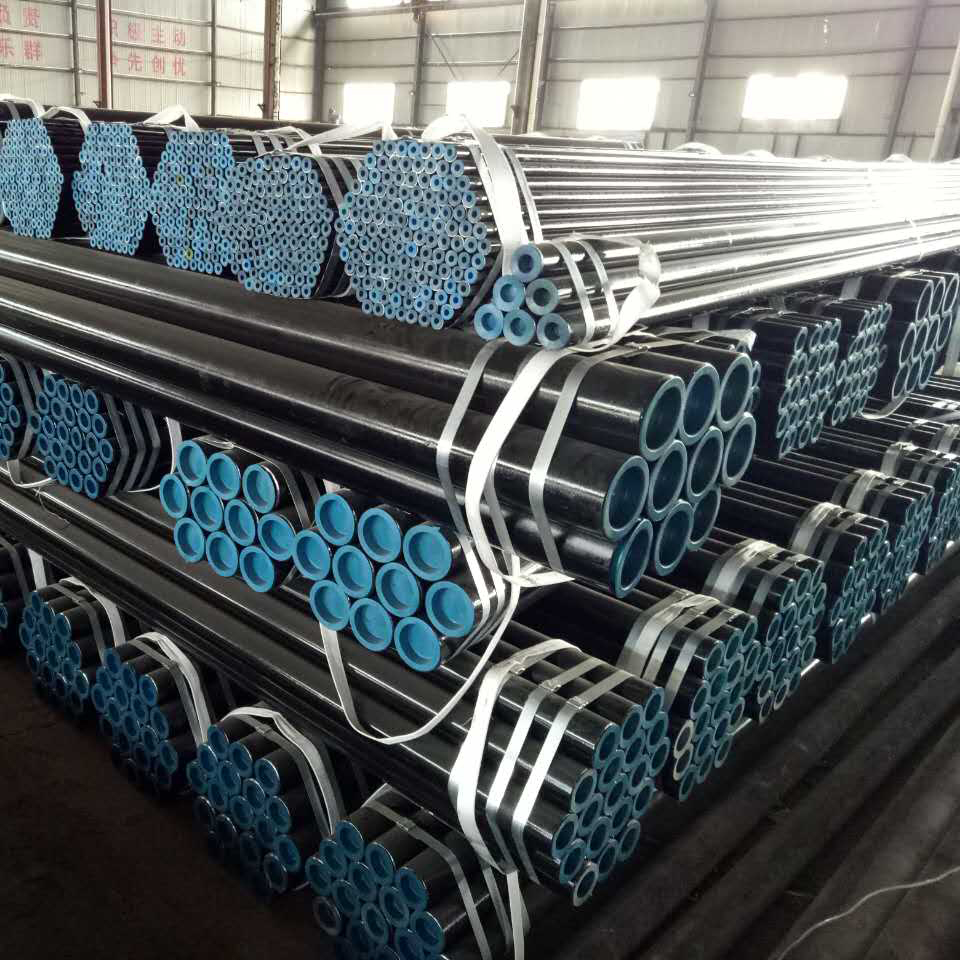

Ipayipi Elingenamthungo Elinwetshiwe Elishisayo

Ipayipi lensimbi elinwebekayo elishisayo amapayipi anwetshiwe angenamthungo ashisayo, anomthamo omncane ophansi kodwa ukufinyela kwepayipi lensimbi eliqinile (ipayipi elingenamthungo) kungabizwa ngokuthi ukunwetshwa okushisayo.Inqubo ye-skew rolling noma indlela yokudweba yokwandisa ububanzi bepayipi.Steel ipayipi ukujiya ngesikhathi esifushane, kungaveza non-standard futhi izinhlobo ezikhethekile amashubhu nekhono nge izindleko eziphansi futhi okusezingeni eliphezulu ukukhiqiza ukusebenza kahle, intuthuko yamanje ngamazwe emkhakheni tube rolling.

Ipayipi elishisayo lokwandisa ngokwandisa ububanzi bepayipi ukuqeda izinqubo - inqubo yokwandisa okushisayo yokukhiqizwa kwepayipi lensimbi.Ipayipi lokunweba elishisayo livame ukubizwa ngamapayipi ensimbi anwetshiwe angenamthungo.

Izinhlaka Zobuchwepheshe Zokunweba Ipayipi Lensimbi Engenamthungo :

| Usayizi omncane | Ngaphandle | Ukuqina Kodonga Lwezibizo (mm) | |||||||||||||

| DN | I-NPS | I-OD(MM) | I-SCH | I-SCH | I-SCH | I-STD | I-SCH | I-SCH | XS | I-SCH | I-SCH | I-SCH | I-SCH | I-SCH | XXS |

| 200 250 300 | 8 10 12 | 219.1 273.1 323.9 | 3.76 4.19 4.57 | 6.35 6.35 6.35 | 7.04 7.80 8.38 | 8.18 9.27 9.53 | 8.18 9.27 10.31 | 10.31 12.70 14.27 | 12.70 12.70 12.70 | 12.70 15.09 17.48 | 15.09 18.26 21.44 | 18.26 21.44 25.40 | 20.62 25.40 28.58 | 23.01 28.58 33.32 | 22.23 25.40 25.40 |

| 350 400 450 | 14 16 18 | 355.6 406.4 457.2 | 6.35 6.35 6.35 | 7.92 7.92 7.92 | 9.53 9.53 11.13 | 9.53 9.53 9.53 | 11.13 12.70 14.27 | 15.09 16.66 19.05 | 12.70 12.70 12.70 | 19.05 21.44 23.83 | 23.83 26.19 29.36 | 27.79 30.96 34.93 | 31.75 36.53 39.67 | 35.71 40.49 45.24 | -- |

| 500 550 600 | 20 22 24 | 508 559 610 | 6.35 6.35 6.35 | 9.53 9.53 9.53 | 12.70 12.70 14.27 | 9.53 9.53 9.53 | 15.09 — 17.48 | 20.62 22.23 24.61 | 12.70 | 26.19 28.58 30.96 | 32.54 34.93 38.89 | 38.10 41.28 46.02 | 44.45 47.63 52.37 | 50.01 53.98 59.54 | -- |

| 500 550 600 | 20 22 24 | 508 559 610 | 6.35 6.35 6.35 | 9.53 9.53 9.53 | 12.70 12.70 14.27 | 9.53 9.53 9.53 | 15.09 — 17.48 | 20.62 22.23 24.61 | 12.70 12.70 12.70 | 26.19 28.58 30.96 | 32.54 34.93 38.89 | 38.10 41.28 46.02 | 44.45 47.63 52.37 | 50.01 53.98 59.54 | -- |

| 660 700 750 | 26 28 30 | 660 711 762 | 7.92 7.92 7.92 | 12.70 12.70 12.70 | — 15.88 15.88 | 9.53 9.53 9.53 | -- | -- | 12.70 12.70 12.70 | -- | -- | -- | -- | -- | -- |

| 800 850 900 | 32 34 36 | 813 864 914 | 7.92 7.92 7.92 | 12.70 12.70 12.70 | 15.88 15.88 15.88 | 9.53 9.53 9.53 | 17.48 17.48 19.05 | -- | 12.70 12.70 12.70 | -- | -- | -- | -- | -- | -- |

| Ngaphandle Ububanzi (mm) / | I-SCH | I-SCH | I-SCH | I-STD | I-SCH | I-SCH | XS | I-SCH | I-SCH | I-SCH | I-SCH | I-SCH |

| 457 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.88 | 29.36 | 34.93 | 39.67 | 45.24 |

| 508 | 6.35 | 9.53 | 12.70 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 |

| 559 | 6.35 | 9.53 | 12.70 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | |

| 610 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.39 | 46.02 | 52.37 | 59.54 |

| 660 | 7.92 | 12.70 | 9.53 | 12.70 | ||||||||

| 711 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||

| 762 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||

| Phawula: Izinga elingenhla kanye nokucaciswa kungokwereferensi nje, singaphinda sikhiqize umkhiqizo owenziwe ngokwezifiso ngokwesicelo sekhasimende. | ||||||||||||

Ukwelashwa okungaphezulu kwepayipi lensimbi:

Ukuze kuthuthukiswe impilo yesevisi yepayipi likawoyela, ukwelashwa okungaphezulu kuvame ukwenziwa ukuze kube lula ukuhlanganiswa okuqinile kwepayipi lensimbi kanye ne-anticorrosive coating.Izindlela zokucubungula ezivamile yilezi: ukuhlanza, ukuchithwa kwamathuluzi, ukucotshwa, ukuqhunyiswa kokudubula okuqeda izigaba ezine.

I-1 yokuhlanza Amafutha, uthuli, i-lubricant, i-organic matter enamathela phezu kwepayipi lensimbi, ngokuvamile isebenzisa i-solvent, i-emulsion ukuhlanza indawo. izindlela zokwelapha ziyadingeka.Ukususwa kokugqwala kwethuluziIpayipi lensimbi elingaphezulu kwe-oxide, ukugqwala, i-welding slag, ingasebenzisa ibhulashi lensimbi yensimbi ukuhlanza nokupholisha indawo yokwelapha.Ukukhipha ithuluzi kungahlukaniswa kube imanuwali namandla, ukuchithwa kwethuluzi okwenziwa ngesandla kungafinyelela ku-Sa

Izinga le-2, ithuluzi lamandla derusting lingafinyelela izinga le-Sa3. Uma ubuso bepayipi lensimbi buhlanganiswe nesikhumba esiqinile se-oxide, kungase kungenzeki ukususa ukugqwala ngosizo lwamathuluzi, ngakho-ke sidinga ukuthola ezinye izindlela.

3 pickling Izindlela ezivamile zokukhetha zihlanganisa ikhemistri kanye ne-electrolysis.Kodwa ukucotshwa kwamakhemikhali kuphela okusetshenziselwa ukuvikela ukugqwala kwepayipi.Ukucosha ngamakhemikhali kungafinyelela izinga elithile lokuhlanzeka kanye nokubamadlakela ebusweni bepayipi lensimbi, elilungele imigqa yehange elandelayo.Ngokuvamile njenge-a ukudubula (isihlabathi) ngemva kokucubungula kabusha.

4 shot ukuqhuma ukuze kukhishwe ukugqwalaNgenjini enamandla amakhulu ukushayela ama-blades azungezayo anesivinini esikhulu, igrit yensimbi, isibhamu sensimbi, ingxenye, amaminerali nolunye izintambo ezilumayo ngaphansi kokusebenza kwamandla aphakathi nendawo kusifutho sepayipi lensimbi kanye nokukhishwa okukhulu, susa ukugqwala, ama-oxide. kanye nokungcola ngakolunye uhlangothi, ngakolunye uhlangothi, ipayipi lensimbi ngaphansi kwesenzo somthelela wodlame olubi namandla okungqubuzana, ukuze kuzuzwe ubulukhuni obufanayo obudingekayo.Phakathi kwezindlela ezine zokwelapha, ukudubula ukuqhuma nokususa kuyindlela ekahle yokwelapha yokususa ipayipi.Ngokuvamile, ukuqhunyiswa kwesibhamu kanye nokususa insimbi kusetshenziselwa ikakhulukazi ukwelashwa kwendawo yangaphakathi yepayipi lensimbi, futhi ukudubula nokususa ipayipi kusetshenziswa kakhulu ukwelapha ngaphandle kwepayipi lensimbi.