Ipuleti lensimbi engagqwali

310/310S ishidi lensimbi engagqwali

Insimbi engagqwali engu-310 i-austenitic chromium nickel yensimbi engagqwali inokumelana okuhle ne-oxidation, ukumelana nokugqwala, ngoba iphesenti eliphakeme le-chromium ne-nickel, i-310 inamandla angcono kakhulu okukhasa, ingaqhubeka nokusebenza ngaphansi kwezinga lokushisa eliphezulu, ukumelana nokushisa okuhle.

I-310S insimbi engagqwali iyinsimbi engagqwali ye-austenitic chromium nickel, inokumelana okuhle ne-oxidation yensimbi engagqwali engu-310S, ukumelana nokuCorrosive.

Umehluko wokwakheka kwamakhemikhali wensimbi engagqwali engu-310/310S

| Ibanga | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | N(%) | Cu(%) |

| 310 | ≤0.25 | ≤1.0 | ≤2.0 | ≤0.03 | --- | 24.0-26.0 | 19.0-22.0 | --- | --- |

| 310S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.03 | ≤0.03 | 24.0-26.0 | 19.0-22.0 | --- | --- |

Umehluko wempahla yeMechanical ye-310/310S yensimbi engagqwali

| Ibanga | amandla aqinileMpa | Isivuno AmandlaMpa | Ukwelula(%) | izinga lokuncipha endaweni(%) | Ukuminyana(g/cm3) |

| 310 | ≥470 | ≥17 | ≥40 | ≥50 | 7.98 |

| 310S | ≥520 | ≥205 | ≥40 | ≥50 | 7.98 |

304/ 304L/ 304H ishidi elingenasici

Mayelana nezinto ezingama-304:I-304 insimbi engagqwali iyinto evamile yensimbi engagqwali, ukuminyana kwe-7.93 g/cm3, imboni ibizwa nangokuthi i-18/8 insimbi engagqwali.Ukumelana nokushisa okuphezulu kwama-degrees angama-800, ngokusebenza kahle kokucubungula, izici zokuqina okuphezulu, okusetshenziselwa kabanzi embonini yokuhlobisa izimboni nefenisha kanye nemboni yokudla.

Mayelana nempahla engu-304L:Insimbi engu-304L njenge-C ephansi esimweni esivamile, ukumelana nokugqwala kwayo kanye no-304 okufanayo, kodwa ngemva kokushisela noma ukucindezeleka ngemva kokuphikiswa kwayo okuhle kakhulu kokugqwala emngceleni wokusanhlamvu.Endabeni ngaphandle kokwelashwa ukushisa, ingahlala ukumelana nokugqwala okuhle, ngokuvamile sebenzisa ama-400 noma ngaphansi (okungezona uzibuthe, izinga lokushisa -196 degrees Celsius kuya ku-800 degrees Celsius).Isetshenziselwa kabanzi ukukhiqiza izidingo ezinhle zokusebenza jikelele (ukumelana nokugqwala kanye nokwakheka) kwemishini nezingxenye.

Mayelana nempahla engu-304H:I-304H iwuhlobo lwensimbi engagqwali, enokugoba okuhle, ukusebenza kwenqubo yokushisela, ukumelana nokugqwala, ukuqina okuphezulu nokuzinza kwenhlangano, ikhono lokuguquguquka elibandayo lihle kakhulu.Izinga lokushisa eliphakeme kakhulu lingafinyelela ku-650 DEG C, futhi ukumelana ne-oxidation kufika ku-850 DEG C.

Umehluko wokubunjwa kwaKhemikhali kwe-304 304L 304H

| Ibanga | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | N(%) | |

| 304 | ≤0.08 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.03 | 18.0-20.0 | 8.0-10.5 | ≤0.1 | |

| 304L | ≤0.03 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.03 | 18.0-20.0 | 8.0-12.0 | ≤0.1 | |

| 304H | 0.04-1.0 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.03 | 18.0-20.0 | 8.0-10.5 | ---- | |

Umehluko wempahla yeMechanical ye-304 304L 304H

| Ibanga | amandla aqinile(Mpa) | Isivuno Amandla(Mpa) | Ukwelula(%) | Ukuqina(HR) |

| 304 | ≥515 | ≥205 | ≥40 | ≥92 |

| 304L | ≥485 | ≥170 | ≥40 | ≥92 |

| 304H | ≥515 | ≥205 | ≥40 | ≥92 |

316/316L ishidi lensimbi engagqwali

Mayelana nezinto ezingama-316:Insimbi engagqwali engu-316 ngokungeza i-Mo element, ukumelana nokugqwala, namandla okushisa aphezulu athuthuke kakhulu, izinga lokushisa eliphezulu lingafinyelela kuma-degree angu-1200-1300, lingasetshenziswa ezimweni ezinzima.Ukumelana nokubola kungcono kune-304 insimbi engagqwali, ekukhiqizeni i-pulp nephepha. inqubo inokumelana nokugqwala okuhle.Futhi insimbi engagqwali engu-316 nayo imelana nokuguguleka komkhathi wezimboni wasolwandle kanye nokugqwala.

Mayelana nempahla engu-316L:Insimbi engagqwali engu-316L inokuqukethwe kwekhabhoni engaphansi kuka-316, evame ukusetshenziswa kuma-pulp kanye nemishini yephepha yokushintshanisa ukushisa, imishini yokudaya, imishini yokugeza ifilimu, amapayipi, izindawo ezisogwini ngaphandle kwezinto zokwakha.Ukumelana nokugqwala kungcono kunezinto ezingama-316.

Umehluko wokwakheka kwamakhemikhali we-316 316L yensimbi engagqwali

| Ibanga | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | Cu(%) |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

Umehluko wempahla yeMechanical ye-316 316L yensimbi engagqwali

| Ibanga | amandla aqinileMpa | Isivuno AmandlaMpa | Ukwelula(%) | izinga lokuncipha endaweni(%) | Ukuminyana(g/cm3) |

| 316 | ≥520 | ≥205 | ≥40 | ≥60 | 7.98 |

| 316L | ≥480 | ≥177 | ≥40 | ≥60 | 7.98 |

430 ishidi lensimbi engagqwali

Insimbi engagqwali engu-430 iwukumelana nokugqwala okuhle kwensimbi evamile, ukusebenza okushisayo kunokuhle kwe-austenitic, i-coefficient yokwandisa okushisayo kune-austenitic encane, ukukhathala kokushisa, engeza isici sokuzinzisa i-titanium, izingxenye ze-weld zisebenza kahle.

430 insimbi engagqwali esetshenziswa ekwakhiweni kwezakhiwo, izingxenye zokushiswa kukaphethiloli, izinto zasendlini, izinto zikagesi zasendlini.

Ukwakheka kwamakhemikhali kwensimbi engagqwali engama-430

| Ibanga | C(%) | Mn(%) | Si(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | Cu(%) |

| 430 | ≤0.12 | ≤1.0 | ≤0.75 | ≤0.04 | ≤0.03 | 16.0-18.0 | ≤0.06 | --- | --- |

Impahla engumshini yensimbi engagqwali engu-430

| Ibanga | amandla aqinileMpa | Isivuno AmandlaMpa | Ukwelula(%) | izinga lokuncipha endaweni(%) | Ukuminyana(g/cm3) |

| 430 | ≥450 | ≥205 | ≥22 | --- | 7.75 |

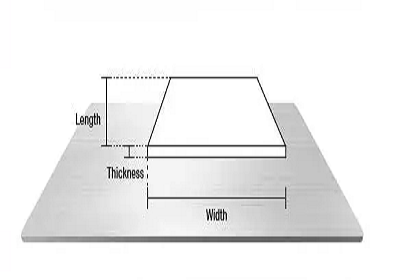

| Ibanga | Qeda | Ubukhulu (mm) | Ububanzi (mm) | Ubude (mm) |

| 310 | 2B / No.4 / HL / BA / Mirror njll | 0.4mm-0.3mm | Ububanzi obujwayelekile e-China: 1000mm 1219mm 1500mm | |

| 310s | No.1 | 3.0mm-80.0mm | Ububanzi obujwayelekile e-China: 1219mm 1500mm 2000mm | |

| 304 | 2B,No.4 PE | 0.55 | 914, 1219 | 1828, 2438 |

| 304 | 2B, No. 4 PE | 0.70 | 914, 1219 | 1828, 2438 |

| 304 | 2B, 2B PE, No. 4 PE, BA PE | 0.90 | 914, 1219 | 1828, 2438 |

| 304 | 2B, 2B PE, No. 4 PE, BA PE | 1.20 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No. 4 PE | 1.50 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No. 4 PE | 1.60 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No. 4 PE | 2.00 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No. 4 PE | 2.50 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No. 4 PE | 3.00 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304L | 2B, 2B PE | 4.00 | 1500, 2000 | 3000, 6000 |

| 304H | 2B / No.4 /HL / BA / Mirror njllNo.1 | 3.00 | 1219, 1500,2000 | |

| 310 | 2B / No.4 / HL / BA / | 0.4-0.3 | 1000,1219,1500 | |

| 310s | No.1 | 3.00 | 1219, 1500,2000 | |

| 316 | 2B | 0.55 | 1219 | 2438 |

| 316 | 2B | 0.70 | 1219 | 2438 |

| 316 | 2B | 0.90 | 1219 | 2438 |

| 316 | 2B,No.4 PE | 1.20 | 1219 | 2438 |

| 316 | 2B,No.4 PE | 1.50 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B,No.4 PE | 1.60 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B,No.4 PE | 2.00 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B,No.4 PE | 2.50 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B,No.4 PE | 3.00 | 1219, 1500 | 2438, 3000, 3658 |

| 316L | 2B, 2B PE | 4.00 | 1500, 2000 | 3000, 6000 |

| 430 | BA PE, No. 4 PE | 0.70 | 914, 1219 | 1828, 2438 |

| 430 | BA PE, No. 4 PE | 0.90 | 914, 1219 | 1828, 2438 |

| 3CR12 | 2B | 1.2 | 1250 | 2500 |

| 3CR12 | 2B | 1.6 | 1250 | 2500 |

| 3CR12 | 2B | 2.0 | 1250 | 2500 |

| 3CR12 | No. 1 | 4.0 | 1250, 1500 | 2500, 3000, 6000 |

Amanye amabanga nobubanzi

Amabanga: 301L, 310, 321, 2205, 253MA.

Ububanzi (mm): 600, 750, 900, 1050, 1200, 1524.

310/310S ishidi lensimbi engagqwali

| Ibanga | I-GB/T 1220-2007 | I-ASTM | I-DIN | I-JIS | KS |

| 310 | 20Cr25Ni20 | 310 | 1.4821 | I-SUS310 | I-STS310 |

| 310S | 06Cr25Ni20 | 310S | 1.4845 | I-SUS310S | I-STS310S |

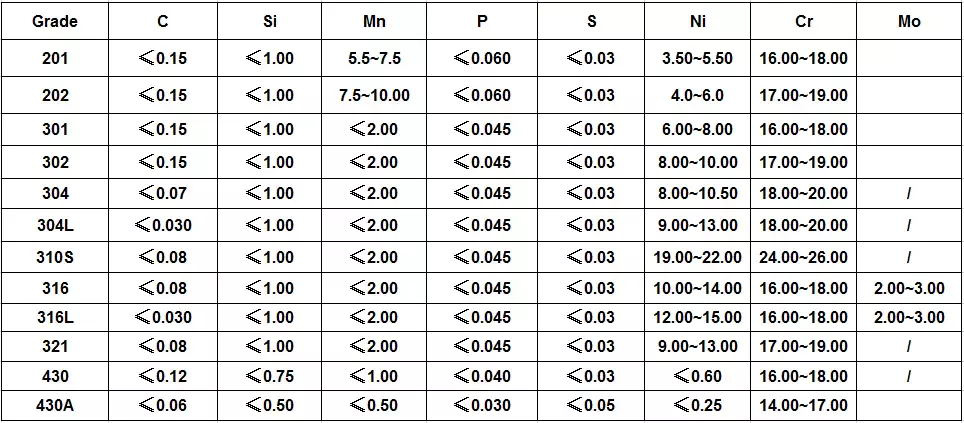

Amazinga we-304 304L 304H stainelss steel

| Ibanga | I-GB/T 1220-2007 | I-ASTM | I-DIN | I-JIS | KS |

| 304 | 06Cr19Ni10 | 304 | 1.4301 | I-SUS304 | I-STS304 |

| 304L | 022Cr19Ni10 | 304L | 1.4306 | I-SUS304L | I-STS304L |

| 304H | —- | 304H | —- | I-SUS304H | I-STS304H |

Amazinga we-316/316L yensimbi engagqwali

| Ibanga | I-GB/T 1220-2007 | I-ASTM | I-DIN | I-JIS | KS |

| 316 | 06Cr17Ni12Mo2 | 316 | 1.4401 | I-SUS316 | I-STS316 |

| 316L | 022Cr17Ni12Mo | 316L | 1.4404 | I-SUS316L | I-STS316L |

Amazinga we430insimbi engagqwali

| Ibanga | GB | I-ASTM | I-DIN | I-JIS |

| 316 | 10Cr17 | 430 | 1.4016 | I-SUS430 |

| Ubukhulu | Isisindo se-Austenitic (kg/m²) | Isisindo se-Ferritic nominal (kg/m²) |

| 0.45 | 3.68 | |

| 0.55 | 4.50 | |

| 0.70 | 5.72 | |

| 0.90 | 7.36 | |

| 1.20 | 9.81 | 9.61 |

| 1.50 | 12.3 | |

| 1.60 | 13.08 | 12.85 |

| 2.00 | 16.35 | 16.02 |

| 2.50 | 20.44 | 20.03 |

| 3.00 | 24.53 | 24.04 |

| 4.00 | 32.71 | 32.06 |

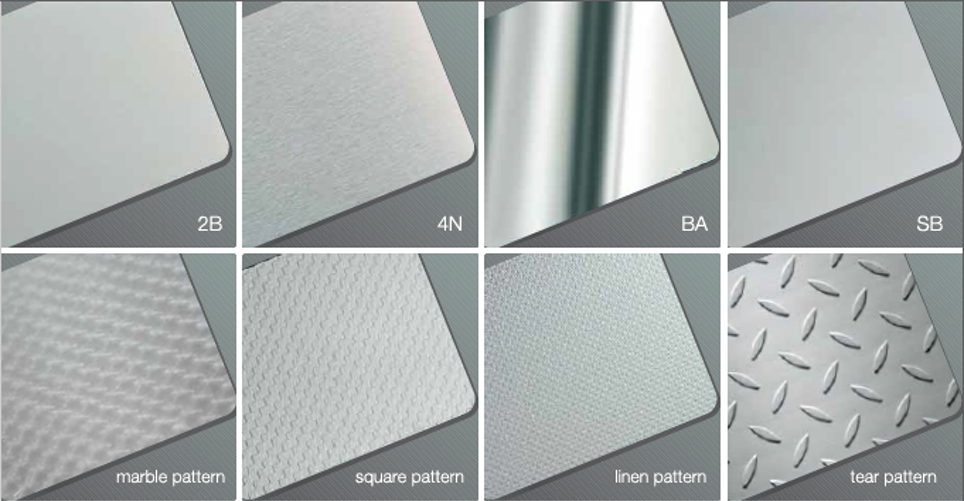

| I-Surface Qeda | Incazelo | Isicelo |

| 2B | Lezo ziqedwa, ngemva kokuginqika okubandayo, ngokuphathwa ukushisa, ukucotshwa noma okunye ukwelashwa okufanayo futhi ekugcineni ngokuginqika okubandayo ukuze kunikezwe ukukhanya okufanele. | Imishini yezokwelapha, Imboni Yokudla, Izinto zokwakha, Izitsha zasekhishini. |

| BA | Lezo zicutshungulwe ngokwelashwa kokushisa okukhanyayo ngemuva kokugoqa okubandayo. | Izitsha zasekhishini, Impahla kagesi, Ukwakhiwa kwebhilidi. |

| NO.3 | Lawo aqedelwa ngokupholishwa ngama-abrasives No.100 kuya ku-No.120 acaciswe ku-JIS R6001. | Izitsha zasekhishini, Ukwakhiwa kwebhilidi. |

| NO.4 | Lawo aqedelwa ngokupholishwa ngama-abrasives No.150 kuya ku-No.180 acaciswe ku-JIS R6001. | Izitsha zasekhishini, Ukwakhiwa kwebhilidi, Imishini yezokwelapha. |

| HL | Lezo eziqediwe zokupholishwa ukuze zinikeze imivimbo yokupholisha eqhubekayo ngokusebenzisa i-abrasive yosayizi ofanele wokusanhlamvu. | Ukwakhiwa Kwezakhiwo. |

| NO.1 | Ingaphezulu liqedwe ukwelashwa kokushisa kanye nokukhetha noma izinqubo ezihambisana lapho ngemva kokugoqa okushisayo. | Ithangi lamakhemikhali, ipayipi. |

| No.8 | Ukuqedwa 'kwesibuko' okubonisa kakhulu.Ikhiqizwe kusukela ekuqedeni kwe-2B ngokupholishwa ngama-abrasive alandelanayo alandela ngokubhafa okubanzi.Isetshenziswa kakhulu ezinhlelweni zezakhiwo. | |

| Ngokuqondene nekhasimende | Ukuqedwa 'kwesibuko' okubonisa kakhulu.Ikhiqizwe kusukela ekuqedeni kwe-2B ngokupholishwa ngama-abrasive alandelanayo alandela ngokubhafa okubanzi.Isetshenziswa kakhulu ezinhlelweni zezakhiwo. |