Ipayipi Elingenasici

Ukuqina :

Amashubhu ensimbi engagqwali avame ukusetshenziswa ukukala ubulukhuni beBrinell, Rockwell kanye neVickers.Ubulukhuni be-Brinell Phakathi kwezindinganiso zamapayipi ensimbi engagqwali, ubulukhuni be-Brinell yibo obusetshenziswa kakhulu, futhi ukuqina kwempahla kuvame ukuvezwa ngobubanzi bokungena, okubili okunembile futhi okulula.Kodwa-ke, ayifaneleki amapayipi ensimbi ensimbi eqinile noma encane.

Ukuqina kwe-Rockwell:

Ishubhu lensimbi engagqwali Ukuhlola ubulukhuni be-Rockwell kuyefana nokuhlola ubulukhuni be-Brinell.Umehluko wukuthi ikala ukujula kwe-indent.Ukuhlolwa kokuqina kwe-Rockwell kuyindlela esetshenziswa kabanzi lapho i-HRC isetshenziswa khona okwesibili ngemuva kokuqina kwe-Brinell HB ezindinganisweni zamapayipi ensimbi.Ubulukhuni be-Rockwell bungasetshenziswa ekunqumeni izinto zensimbi ukusuka ekuthambile kakhulu kuye kokuqina kakhulu.Inxephezela indlela ye-Brinell.Ilula kunendlela ye-Brinell futhi ingafunda ngokuqondile inani lokuqina kusuka kumshini wokuqina.Kodwa-ke, ngenxa yokuhlehlisa okuncane, inani lokuqina alinembile njengendlela ye-Brinell.

Vickers ubulukhuni

Ishubhu yensimbi engagqwali yokuhlola ubulukhuni be-Vickers nayo iyindlela yokuhlola yokuhlehlisa yokulinganisa izinto zensimbi ezacile kakhulu kanye nokuqina kongqimba lwangaphezulu.Inezinzuzo eziyinhloko zezindlela ze-Brinell ne-Rockwell, futhi inqoba ukushiyeka kwayo okuyisisekelo, kodwa ayilula njengendlela ye-Rockwell.Indlela ye-Vickers ayivamisile ukusetshenziswa ezindinganisweni zamapayipi ensimbi.

Ukuhlolwa kokuqina

Ishubhu lensimbi engagqwali linobubanzi obungaphakathi obungu-6.0mm noma ngaphezulu kanye neshubhu lensimbi engenasici elinogqinsi oluyi-13mm noma ngaphansi.Kungaba i-W-B75 yokuhlola ubulukhuni be-Vickers.Kuyashesha kakhulu futhi kulula ukuhlola futhi kulungele ukuhlolwa okusheshayo nokungonakali kwamapayipi ensimbi engagqwali.Amashubhu ensimbi engagqwali anobubanzi bangaphakathi obungaphezu kuka-30 mm nogqinsi lodonga olukhulu kuno-1.2 mm ahlolwa ngesihloli sokuqina se-Rockwell ukuze kuhlolwe ubulukhuni be-HRB ne-HRC.Amashubhu ensimbi engagqwali anobubanzi bangaphakathi obungaphezu kuka-30 mm nogqinsi olungaphansi kuka-1.2 mm ahlolwa ngomshini wokuhlola ubulukhuni be-Rockwell ukuze kuhlolwe ubulukhuni be-HRT noma i-HRN.Emapayipini ensimbi engagqwali anobubanzi bangaphakathi obungaphansi kuka-0 mm nangaphezulu kuka-4.8 mm, ubulukhuni be-HR15T kuhlolwa umhloli wokuqina we-Rockwell okhethekile wamapayipi.Lapho ububanzi bangaphakathi beshubhu yensimbi engagqwali bukhulu kuno-26 mm, ukuqina kodonga lwangaphakathi lweshubhu nakho kungahlolwa yi-Ro.

Ukwakheka Kwamakhemikhali

| Amabanga | C max | Mn max | P max | S max | Simax | Cr | Ni | Mo |

| 304 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-11.00 | / |

| 304L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Izakhiwo Zemishini

| Amabanga | I-Itemper | Tensile Psi | Isivuno Psi | Elong % | Ukuqina kwe-Rockwell |

| 304 | I-Annealed | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | I-Annealed I1/8 Kanzima | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | I-Annealed | 85000 imiz | 35000 min | 50 imiz | 80 imiz |

| I-Annealed | 80000 min | 30000 min | 50 imiz | 75 imiz |

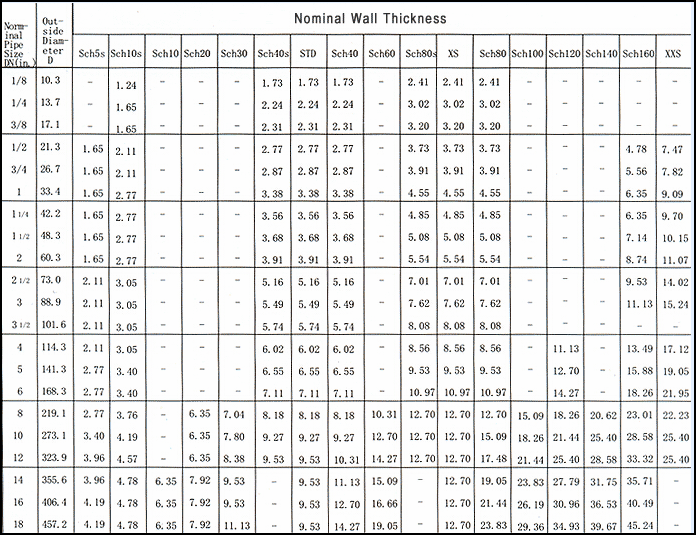

Osayizi Bepayipi Lensimbi Engagqwali

I-annealed & pickled, i-annealing ekhanyayo, ipholishiwe

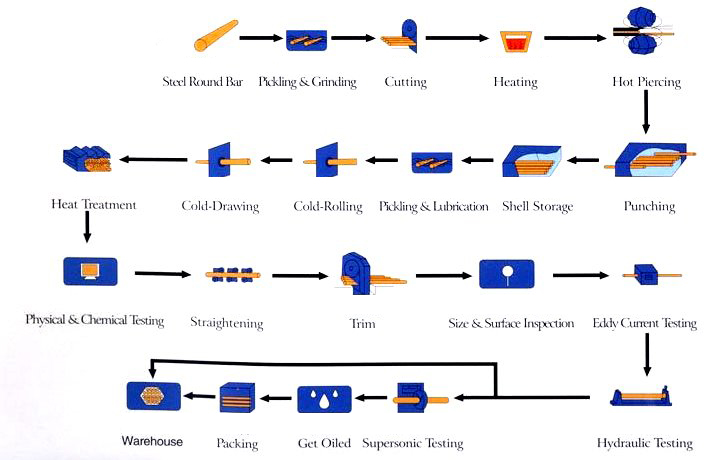

Inqubo