Ipayipi Lokubhoboza Isisindo Esisindayo

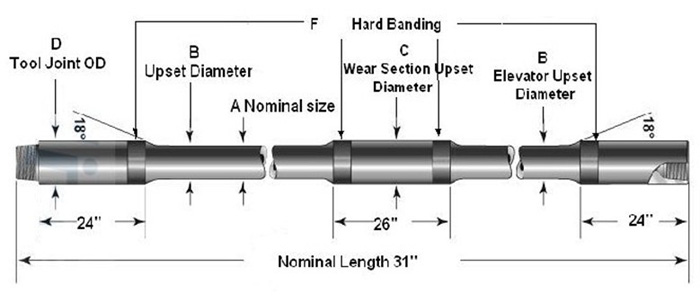

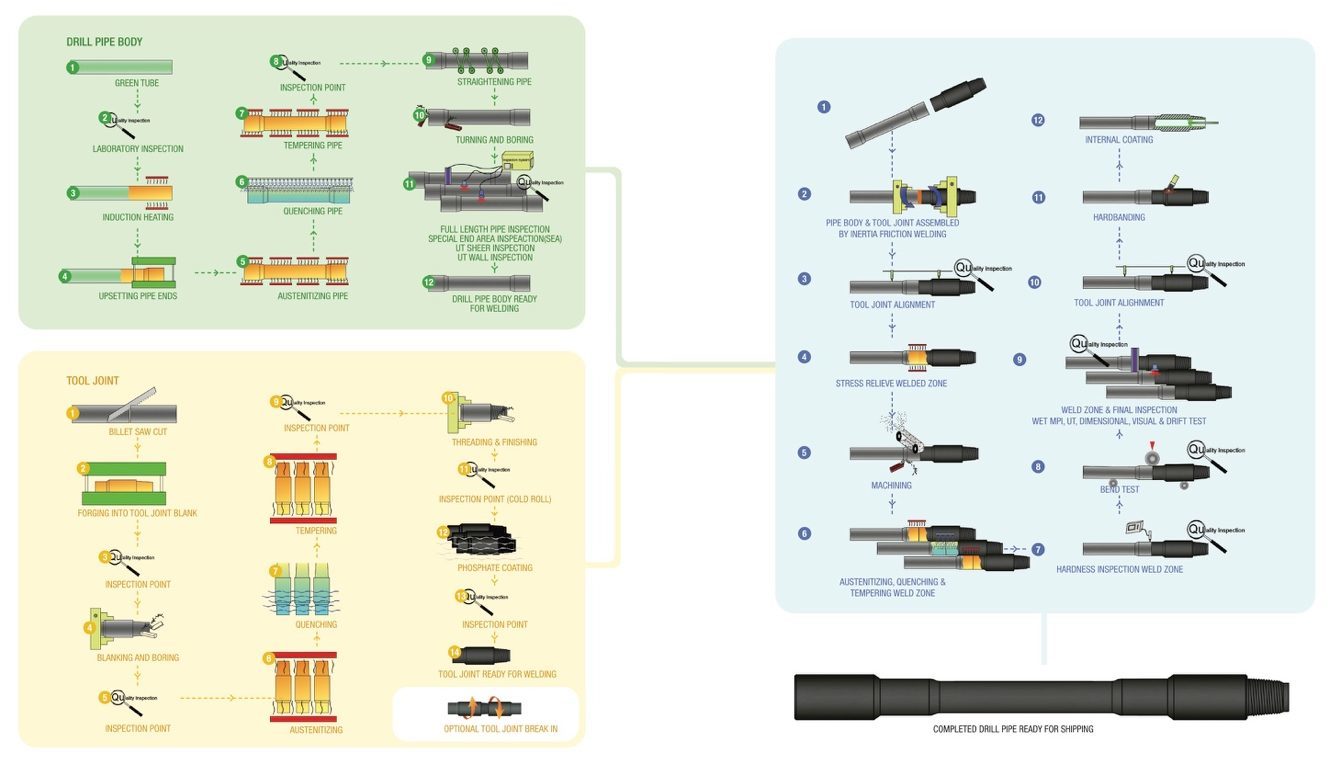

Ipayipi lokubhoboza elisindayo elihlanganisiwe liyindawo yoshintsho phakathi kwekholomu yokubhoboza nepayipi lokubhoboza.Akukwazi nje ukunciphisa ukwakheka kokucindezeleka ekuxhumekeni kwekhola yokubhoboza kanye nepayipi yokubhoboza, kodwa futhi kunciphise ukuguga ku-OD.

Ipayipi lokubhoboza elisindayo elihlanganisiwe lenziwa ngocezu olulodwa lwebha eqinile ye-AISI 4145H, liphathwe ngokushisa ngokugcwele, zonke izakhiwo ezibonakalayo zihambisana ne-API spec7 uhlelo lwakamuva.

Ibhande eliqinile lokumelana nokugqoka kwe-HWDP lijwayelekile ekuxhumekeni kwamalunga amathuluzi kanye nokucasuka okumaphakathi.Izinhlobo zamabhendi aqinile zifaka i-Arnco 100XT ne-100XT.Zonke izintambo zenziwe nge-phosphated, zenziwe ngethusi noma zibandayo.Konke ukuxhumana kufakwe izivikeli zentambo zensimbi ezicindezelwe.Zonke izikhangisi zenziwa ngomshini ngezinsimbi ze-CNC -Imicu enamahlombe amabili futhi ekhethekile.

Ukucaciswa kwezobuchwepheshe kanye nemingcele

| Usayizi(in) | OD (ngaphakathi) | I-ID (in) | I-Tool Joint OD (in) | I-ID Ehlangene Yethuluzi (in) | Ukuxhumana | I-Max.elevator diameter (in) | I-Central upset dia.(ngaphakathi) | Min.drift dia.size(in) |

| 3 1/2 | 3 1/2 | 2 1/4 | 4 3/4 | 2 1/4 | NC38 | 3 7/8 | 4 | 2 |

| 2 1/16 | 2 1/16 | 1 13/16 | ||||||

| 4 | 4 | 2 1/2 | 5 1/4 | 2 1/2 | I-NC40 | 4 3/16 | 4 1/2 | 2 1/4 |

| 2 9/16 | 2 9/16 | 2 5/16 | ||||||

| 4 1/2 | 4 1/2 | 2 11/16 | 6 1/4 | 2 11/16 | NC46 | 4 11/16 | 5 | 2 7/16 |

| 2 3/4 | 2 3/4 | 2 1/2 | ||||||

| 2 13/16 | 2 13/16 | 2 9/16 | ||||||

| 5 | 5 | 3 | 6 5/8 | 3 | NC50 | 5 1/8 | 5 1/2 | 2 3/4 |

| 5 1/2 | 5 1/2 | 3 1/4 | 7 | 3 1/4 | 5 1/2 FH | 5 11/16 | 6 | 3 |

| 3 3/8 | 3 3/8 | 3 1/8 | ||||||

| 3 7/8 | 3 7/8 | 3 5/8 | ||||||

| 4 | 4 | 3 3/4 | ||||||

| 6 5/8 | 6 5/8 | 4 | 8 | 4 | 6 5/8 FH | 6 15/16 | 7 1/8 | 3 3/4 |

| 4 1/2 | 4 1/2 | 4 1/4 | ||||||

| 5 | 5 | 4 3/4 |

| Kuvunguza ipayipi lokubhoboza elisindayo | ||||||||

| Ukucaciswa mm | Ithubhu | Okuhlangene | ||||||

| I-ID mm | I-Elevator iphazamisekile | i-lifti groove /Slip ngaphandle kwe-diametermm | Isikulufu nge-diametermm | I-Spiral groove deepmm | Uhlobo Lwentambo | OD mm | I-ID mm | |

| 88.9(3 1/2) | 54 | 92.1 | 88.9 | 101.6 | 9.5 | NC38 | 120.6 | 54 |

| 114.3(4 1/2) | 69.8 | 117.5 | 114.3 | 127 | 12.7 | NC46 | 158.8 | 69.8 |

| 127.0(5) | 76.2 | 130.2 | 127 | 139.7 | 12.7 | NC50 | 165.1 | 76.2 |

| Insimbi Mark | Ukwakheka Kwekhemikhali% | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Al | |

| 4145H | 0.42~0.48 | 0.15~0.35 | 0.90~1.20 | ≤0.03 | ≤0.03 | 0.90~1.20 | 0.15~0.25 | ≤0.2 | 0.025~0.045 |

| Ezinye Izinto:N≤0.015,Ni≤0.5 | |||||||||

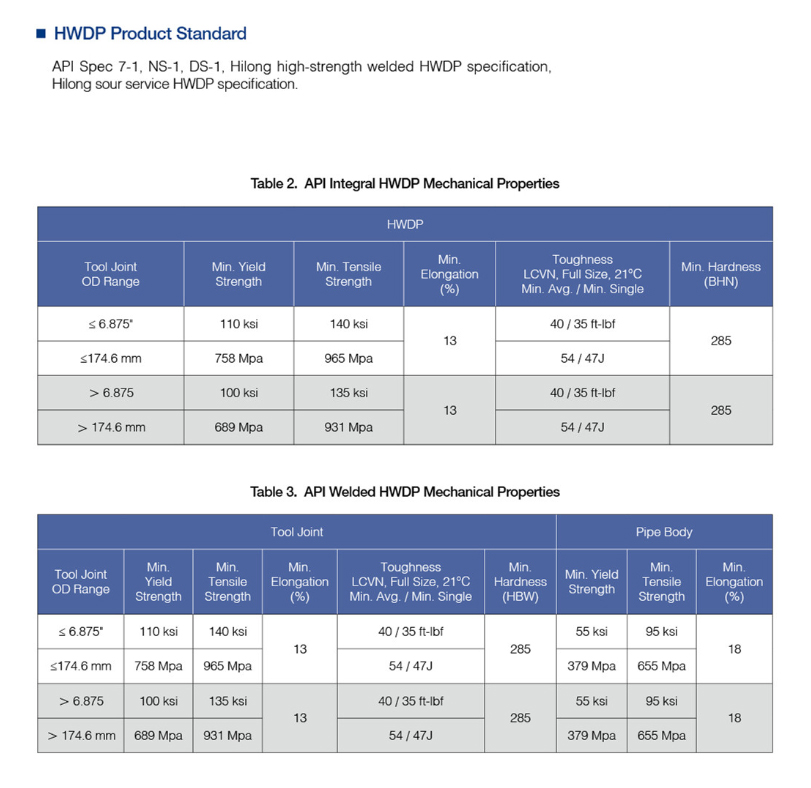

| Isicelo | Okubalulekile | Usayizi | Amandla Okukhiqiza (Min KSI) | Amandla Aphezulu (Min KSI) | I-Harness Brinell (HB) | Ubude (A%) | I-Min CHarpy (ft-lbs @+20°C) |

| Izinga Eliphelele | I-AISI 4145H Ishintshiwe | Konke | 110 | 140 | 285 kuya ku-340 | 13 | 40 |

| I-Welded Standard | I-AISI 1340 Modified | Konke | 65 | 95 | 235 (ubukhulu) | 18 | 30 |

| I-NS-1 eshiselwe | I-AISI 4140H Ishintshiwe | Konke | 120 | 140 | 285 kuya ku-340 | 13 | 40 |

| I-Welded Standard | I-AISI 4140H Ishintshiwe | Ngaphezulu kokungu-7 1/4” | 120 | 140 | 285 kuya ku-340 | 13 | 40 |

| Okushiselwe okujwayelekile | I-AISI 4140H Ishintshiwe | Kufika ku-7 1/4” | 100 | 135 | 285 kuya ku-340 | 13 | 40 |

| HWDP-110 HW MS | U-ASCOWELL C | Ngaphezulu kuka-6 3/4” | 110 | 140 | 285 kuya ku-340 | 13 | 0 |

| HWDP-110 HW MS | U-ASCOWELL C | Kufika ku-6 3/4” | 100 | 135 | 285 kuya ku-340 | 13 | 55 |

| I-HWDP-65 HW MS (ithuluzi elihlangene) | U-ASCOWELL C | Ngaphezulu kuka-6 3/4” | 110 | 140 | 285 kuya ku-340 | 13 | 55 |

| I-HWDP-65 HW MS (ithuluzi elihlangene) | U-ASCOWELL C | Kufika ku-6 3/4” | 100 | 135 | 285 kuya ku-340 | 13 | 55 |

| HWDP-65 HW MS | I-AISI 1340 Modified | Konke | 65 | 95 | 235 (ubukhulu) | 18 | 30 |