Ipayipi Elishiselwe I-Carbon Steel

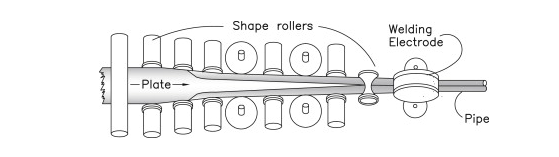

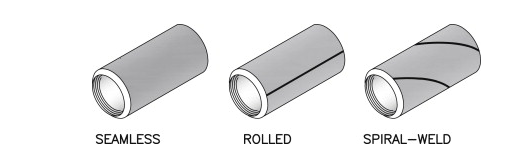

Ipayipi elishiselwe ngezinqe lakhiwa ngokuphakela ipuleti lensimbi elishisayo ngokusebenzisa ama-shapers azoligoqa libe yisimo esiyindilinga esingenalutho.Ukucindezela iziphetho ezimbili zepuleti ndawonye kuzokhiqiza inhlanganisela ehlanganisiwe noma umthungo.Umfanekiso 2.2 ubonisa ipuleti lensimbi njengoba liqala inqubo yokwenza ipayipi elishiselwe ngezinqe

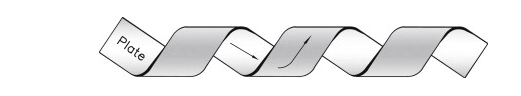

Okungajwayelekile kakhulu kulezi zindlela ezintathu ipayipi elishiselwe ku-spiral.Ipayipi eline-spiral-welded lakhiwa ngamapheshana ensimbi asontekile abe umumo ozungezayo, ofana nomgundi wezinwele's pole, bese i-welding lapho imiphetho ihlangana khona ukuze yenze umthungo.Lolu hlobo lwepayipi luvinjelwe ezinhlelweni zamapayipi zisebenzisa izingcindezi eziphansi ngenxa yezindonga zalo ezincane.Umfanekiso 2.3 ukhombisa ipayipi eli-spiral-welded njengoba livela ngaphambi kokushisela.

Ngayinye yezindlela ezintathu zokukhiqiza ipayipi inezinzuzo zayo kanye nokubi.Ipayipi elishiselwe ngezinqe, ngokwesibonelo, lakhiwa ngepuleti eligoqiwe elinogqinsi olufana nolwengeziwe futhi lingahlolwa ukuthi alinasici yini ngaphambi kokwakheka nokushisela.Le ndlela yokukhiqiza iwusizo ikakhulukazi lapho kudingeka izindonga ezincane nobude obude.Ngenxa yomthungo oshiselwe, nokho, kuhlale kunethuba lokulimala okuphunyuka ekuhlolweni okuningi kokulawulwa kwekhwalithi okwenziwa phakathi nenqubo yokukhiqiza.

Ngenxa yalokho, i-American National Standards Institute (ANSI) yakha iziqondiso eziqinile zokwenziwa kwamapayipi.I-Pressure Piping Code B31 yabhalelwa ukulawula ukwenziwa kwepayipi.Ikakhulukazi, i-code B31.1.0 inika amandla angu-85% epayipi eligoqiwe, ama-60% amapayipi ashiselwe ku-spiral, kanye nokusebenza kahle kuka-100% kumapayipi angenamthungo.

Ngokuvamile, ukuqina kwezindonga ezibanzi kukhiqizwa ngendlela engenamthungo.Kodwa-ke, ekusetshenzisweni okuningi kokucindezela okuphansi kwepayipi, indlela eqhubekayo ehlanganisiwe iyona eyonga kakhulu.Ipayipi elingenamthungo likhiqizwa ngobude obungahleliwe obubodwa nakabili.Ubude obubodwa obungahleliwe buhluka kusuka ku-16'-0″kuye 20'-0″.Amapayipi 2″futhi ngezansi zitholakala ngobude obuphindwe kabili obungahleliwe obulinganisa ukusuka ku-35'-0″kuye 40'-0″.

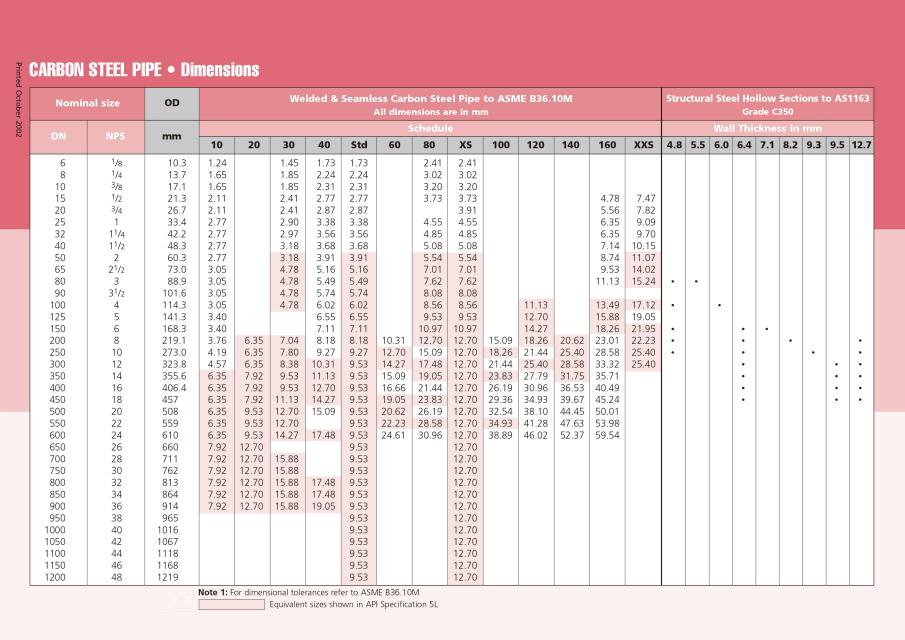

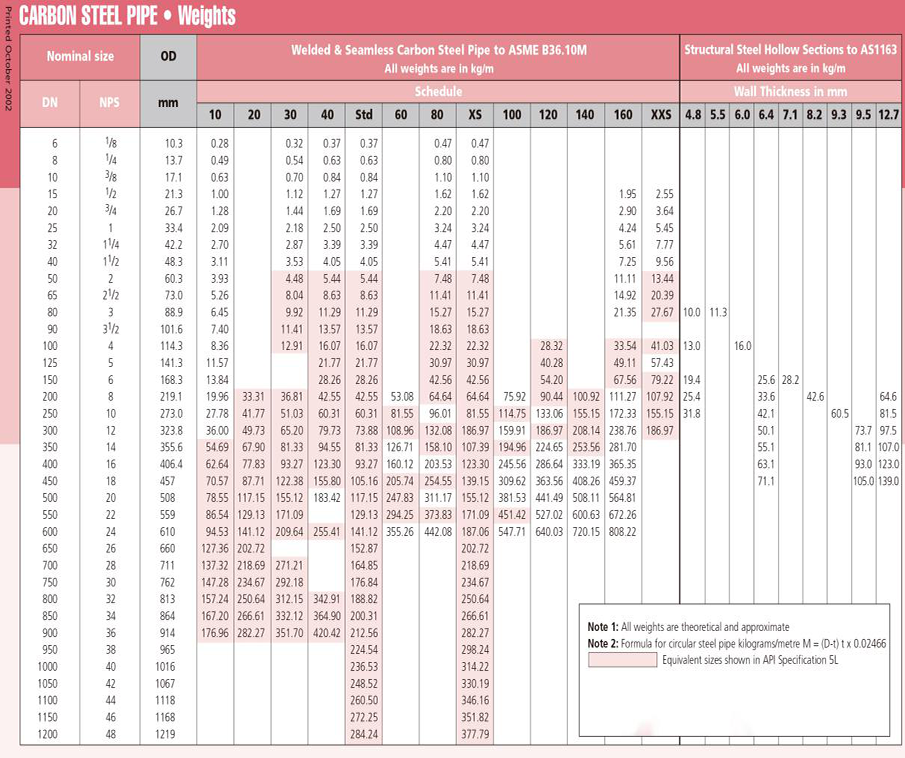

I-Carbon steel welded & i-seamless pipe izilinganiso nezisindo

| Ipayipi Lekhabhoni, Ukufakwa kanye namaFlange | |

| Ifomu | Ishiselwe (ERW) futhi Ayinamthungo |

| Isicelo | Uketshezi, Isakhiwo |

| Ububanzi besayizi | I-DN15 – DN600 |

| Amabanga | 250, 350 |

| Ukuqina Kwezindonga | Std Wt, XS |

| Uhlobo Lokufakwayo | I-Butt weld, i-Screwed & socket, i-Flanges, i-Flanges emnyama kanye ne-Galvanized fittings ku-EN10241 (BS 1740) |

| Umumo Wokufaka | Izindololwane, Amazinyo, Izinciphisa, Ofeleba, Iziphetho ze-Stub, Ama-Flanges (ANSI, Ithebula E, D kanye no-H) |

| Iyacubungula | Sika-kuya-ubude, |

Ishidi lokucaciswa kwepayipi elishiselwe ngqo

| Ukucaciswa (mm) | OD(ububanzi bangaphandle) | ukujiya kodonga | isisindo | |

| 1/2 intshi | 21.25 | 2.75 | 1.26 | |

| 3/4 intshi | 26.75 | 2.75 | 1.63 | |

| 1 intshi | 33.3 | 3.25 | 2.42 | |

| 11/4 intshi | 42.25 | 3.25 | 3.13 | |

| 11/2 intshi | 48 | 3.5 | 3.84 | |

| 2 intshi | 60 | 3.5 | 4.88 | |

| 21/2 intshi | 75.5 | 3.75 | 6.64 | |

| 3 intshi | 88.5 | 4.0 | 8.34 | |

| 4 intshi | 114 | 4.0 | 10.85 | |

| 5 intshi | 140 | 4.5 | 15.04 | |

| 6 intshi | 165 | 4.5 | 17.81 | |

| 8 intshi | 219 | 6 | 31.52 | |

Ithebula lokucaciswa kwepayipi eligoqiwe eligoqiwe

| ukucaciswa | ukujiya kodonga | Isisindo imitha ngayinye | Inani lomfutho wamanzi elijwayelekile likazwelonke | Inani lokucindezela kwamanzi okuzisholo | ukucaciswa | ukujiya kodonga | Isisindo ngemitha ngayinye | Inani lomfutho wamanzi elijwayelekile likazwelonke | Inani lokucindezela kwamanzi okuzisholo |

| 219 | 6 | 32.02 | 9.7 | 7.7 | 720 | 6 | 106.15 | 3 | 2.3 |

| 7 | 37.1 | 11.3 | 9 | 7 | 123.59 | 3.5 | 2.7 | ||

| 8 | 42.13 | 12.9 | 10.3 | 8 | 140.97 | 4 | 3.1 | ||

| 273 | 6 | 40.01 | 7.7 | 6.2 | 9 | 158.31 | 4.5 | 3.5 | |

| 7 | 46.42 | 9 | 7.2 | 10 | 175.6 | 5 | 3.9 | ||

| 8 | 52.78 | 10.3 | 8.3 | 12 | 210.02 | 6 | 4.7 | ||

| 325 | 6 | 47.7 | 6.5 | 5.2 | 820 | 7 | 140.85 | 3.1 | 2.4 |

| 7 | 55.4 | 7.6 | 6.1 | 8 | 160.7 | 3.5 | 2.7 | ||

| 8 | 63.04 | 8.7 | 6.9 | 9 | 180.5 | 4 | 3.1 | ||

| 377 | 6 | 55.4 | 5.7 | 4.5 | 10 | 200.26 | 4.4 | 3.4 | |

| 7 | 64.37 | 6.7 | 5.2 | 11 | 219.96 | 4.8 | 3.8 | ||

| 8 | 73.3 | 7.6 | 6 | 12 | 239.62 | 5.3 | 4.1 | ||

| 9 | 82.18 | 8.6 | 6.8 | 920 | 8 | 180.43 | 3.1 | 2.5 | |

| 10 | 91.01 | - | 7.5 | 9 | 202.7 | 3.5 | 2.8 | ||

| 426 | 6 | 62.25 | 5.1 | 4 | 10 | 224.92 | 3.9 | 3.1 | |

| 7 | 72.83 | 5.9 | 4.6 | 11 | 247.22 | 4.3 | 3.4 | ||

| 8 | 82.97 | 6.8 | 5.3 | 12 | 269.21 | 4.7 | 3.7 | ||

| 9 | 93.05 | 7.6 | 6 | 1020 | 8 | 200.16 | 2.8 | 2.2 | |

| 10 | 103.09 | 8.5 | 6.7 | 9 | 224.89 | 3.2 | 2.5 | ||

| 478 | 6 | 70.34 | 4.5 | 3.5 | 10 | 249.58 | 3.5 | 2.8 | |

| 7 | 81.81 | 5.3 | 4.1 | 11 | 274.22 | 3.9 | 3 | ||

| 8 | 93.23 | 6 | 4.7 | 12 | 298.81 | 4.2 | 3.3 | ||

| 9 | 104.6 | 6.8 | 5.3 | 1220 | 8 | 239.62 | - | 1.8 | |

| 10 | 115.92 | 7.5 | 5.9 | 10 | 298.9 | 3 | 2.3 | ||

| 529 | 6 | 77.89 | 4.1 | 3.2 | 11 | 328.47 | 3.2 | 2.5 | |

| 7 | 90.61 | 4.8 | 3.7 | 12 | 357.99 | 3.5 | 2.8 | ||

| 8 | 103.29 | 5.4 | 4.3 | 13 | 387.46 | 3.8 | 3 | ||

| 9 | 115.92 | 6.1 | 4.8 | 1420 | 10 | 348.23 | 2.8 | 2 | |

| 10 | 128.49 | 6.8 | 5.3 | 14 | 417.18 | 3.2 | 2.4 | ||

| 630 | 6 | 92.83 | 3.4 | 2.6 | 1620 | 12 | 476.37 | 2.9 | 2.1 |

| 7 | 108.05 | 4 | 3.1 | 14 | 554.99 | 3.2 | 2.4 | ||

| 8 | 123.22 | 4.6 | 3.6 | 1820 | 14 | 627.04 | 3.3 | 2.2 | |

| 9 | 138.33 | 5.1 | 4 | 2020 | 14 | 693.09 | - | 2 | |

| 10 | 153.4 | 5.7 | 4.5 | 2220 | 14 | 762.15 | - | 1.8 |

Igcotshwe kancane, Idiphu elishisayo lifakwe ithala, i-Electro

i-galvanized, iMnyama, i-Bare, i-varnish coating / i-anti rust oil,

Izingubo Zokuzivikela