Ipayipi Lensimbi Elivunyiwe

Ipayipi eliqinile elingenamthungo lihlukaniswe ipayipi elibandayo elicwecwe lensimbi elingenamthungo kanye nepayipi elishisayo lokucwilisa elingenamthungo.

Ipayipi elishisayo lokucwilisa elingenamthungo

Ipayipi le-Redu elingenamthungo liwukwenza ukusabela kwensimbi encibilikisiwe ne- iron substrate, ungqimba lwengxubevange, ukuze i-substrate engaphansi nenhlanganisela yakho kokubili.I-Hot-dip galvanizing iwukuqala kwensimbi yensimbi, ukuze kususwe ipayipi lensimbi le-iron oxide, i-pickling, isixazululo esinamanzi se-ammonium chloride noma i-zinc chloride noma i-ammonium chloride ne-zinc chloride exutshwe ne-aqueous solution tank yokuhlanza, bese ithumela endaweni eshisayo. ithangi lokucwilisa.I-hot dip galvanized coating ukufana, ukunamathela okuqinile, nokuphila isikhathi eside.

Ipayipi elibandayo elingenamthungo

Amakhaza amakhaza, electro-lashukumisa inani elincane, 10-50g/m2 kuphela ukumelana ukugqwala kuka dip hot ipayipi lashukumisa okuningi umehluko.Abakhiqizi bamapayipi avamile, ukuze kuqinisekiswe ikhwalithi, iningi alisebenzisi i-electro-galvanized (cold-plated).Yilabo kuphela abancane, amathuluzi aphelelwe yisikhathi kanye namabhizinisi amancane anamagala kagesi, yiqiniso, amanani abo ashibhile.UMnyango Wezokwakha uye ngokusemthethweni ngezansi, ipayipi likathayela abandayo ukuqeda ubuchwepheshe emuva, ikusasa angavunyelwe ukubanda ipayipi lashukumisa amanzi, igesi amapayipi.

Izakhiwo zemishini ezingenamthungo ezikhandiwe

Izakhiwo zemishini yensimbi iwukuqinisekisa ukuthi inkomba ebalulekile yezakhiwo zensimbi zokugcina (izakhiwo zemishini), kuncike ekubunjweni kwamakhemikhali kanye nokwelashwa kokushisa kwensimbi.Izindinganiso zensimbi, ngokwezidingo ezihlukene, izinhlinzeko zezakhiwo eziqinile (amandla aqinile, amandla esivuno noma ukuphakama kwephoyinti lesivuno) nobulukhuni, ukuqina, izidingo zomsebenzisi, ukusebenza okuphezulu nokuphansi kwezinga lokushisa.

Isicelo:

1.Impahla yokwakha kanye nesakhiwo

2.Izinjongo zobunjiniyela nobunjiniyela obujwayelekile

3.Ukwenziwa Komzimba Webhasi, Izitimela Zesitimela

4.Emnyangweni Wezingcingo njengamapayipi epayipi

I-Material Inspection (Ipayipi Lensimbi) — Ukulenga — De-greasing — Rinsing — Pickling — Washing — Dipping Fluxing — Hot Air Drying — Inside and Outside Hot-dipped Galvanizing Blow— Cooling — Passivation and Rising — Unloading — Inspection and Trimming — Type Identification — Ukupakisha Nokugcina kanye Nezokuthutha

Izinhlobo: Ipayipi lensimbi elishiselwe i-galvanzied, ipayipi lensimbi elingenamthungo

Izinto: Carbon steel

Uhlobo lokuxhuma: intambo

Ibanga losayizi:1/8″-36″

Ishejuli: sch40, sch80, sch120, sch160, XH, XXH

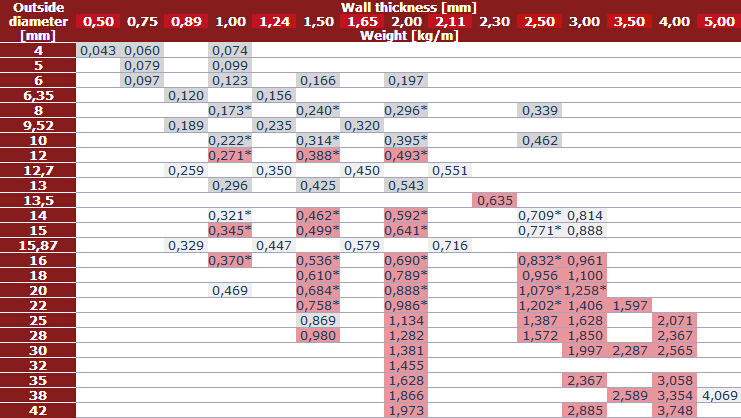

Ubude bamashubhu athathiwe

- ububanzi 4 - 16 mm 6000 + 100 mm

- ububanzi 18 - 42 mm 6000 + 50 mm

Ukubekezelela amashubhu ahlanganiswe ne-zinc

- ukubekezelelwa kwe-diameter yangaphandle:

- ububanzi obuphakathi kuka-4 - 30 mm±0,08 mm

- ububanzi buphakathi kwama-35 - 38 mm±0,15 mm

- ububanzi kufika ku-42 mm±0,20 mm

- Ukubekezelelwa kobubanzi bangaphakathi kuhambisana ne-EN 10305-4

- ukubekezelela ukushuba odongeni± 10%

Amabanga ensimbi amashubhu ahlanganiswe ne-zinc

I-E 235+N kanye ne-E 355+N

Isimo esingaphezulu samashubhu anothayela

Isendlalelo sokuqala-i-zinc ekhishwe ngogesi (Zn)-isebenza njenge-anode futhi endaweni eyonakalisayo iqala ukugqwala futhi isisekelo sensimbi sivikeleke ngendlela engagculisi ekugqwaleni.Ugqinsi longqimba lwezinki lungase lube sebangeni lama-micrometer angu-5 ukuya kwangu-30 (µm).