Ipayipi elicijile

Amapayipi e-casing casing asetshenziswa ekuhloleni uwoyela angavimbela isihlabathi esingama-99%, ehlise u-80% wokugcinwa kanzima komthombo kawoyela, futhi andise amandla omthombo kawoyela, ubuqotho kanye nokuzinza kokugcina isihlabathi singekho.Ngaleso sikhathi, ubuchwepheshe be-laser incision bungenza i-slot ibe bushelelezi futhi inembe.Isakhiwo sepayipi le-casing slotted liyisampula, kodwa lisebenza kahle kakhulu.

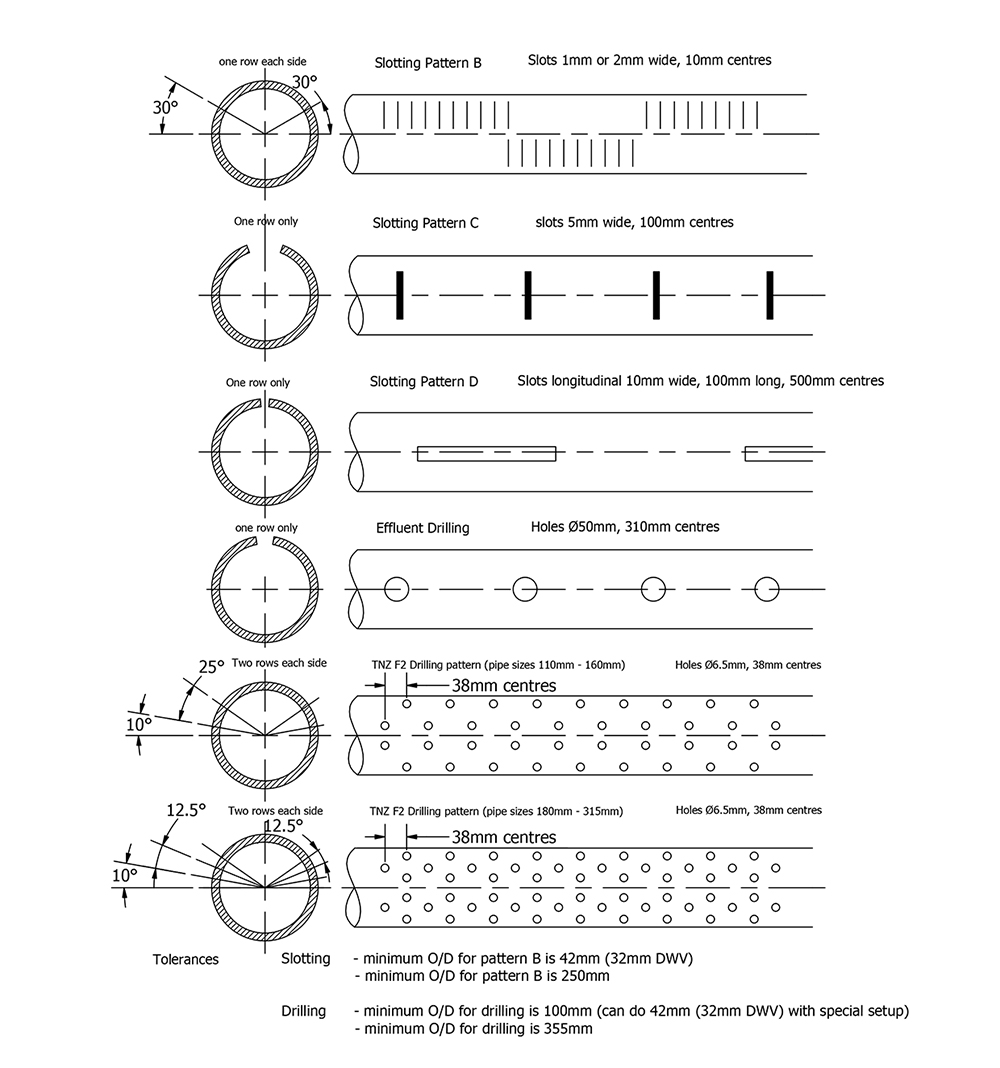

Ukucutshungulwa kweshubhu elifakwe kumandla aphezulu emzimbeni wensimbi onezindlela zokusebenza ezibandayo noma ezishisayo, ukusika amakhulu ezinkulungwane zemifantu ye-longitudinal, imifantu evame ukusetshenziswa ukucaciswa: ububanzi bomthungo 0.15 3 mm, ububanzi nakakhulu, igebe ubude 50-200 mm.Isigaba sesiphambano izinhlobo yilezi: unxande, isitebhisi esimise okwesitebhisi, esiqondile futhi esihlukahlukene, siphinde sibe nesikrini segroove esiyindilinga, imininingwane yokuvula ububanzi bembobo ububanzi obuyi-5-20 mm ngamamitha. isigaba somumo wedigri ehlanzekile, onqenqemeni lomthungo wembobo ubushelelezi kanye nezinga lokumelana nokugqwala komthungo wembobo.

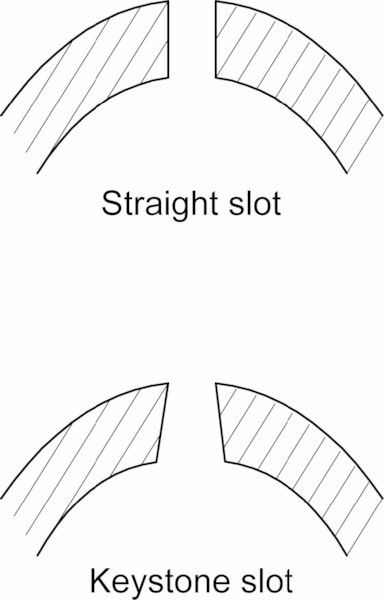

Slots Straight-Izikhala zisikwa ngobubanzi obulinganayo ngodonga lwepayipi kokubili i-ID ne-OD.Kucaciswe lapho ibhuloho lezinhlamvu zesihlabathi esikhaleni lingabalulekile kakhulu, izikhala eziqondile zimelana kakhulu kunezikhala zamatshe angukhiye ezithungelwe futhi kubiza kancane ukuzikhiqiza.Izicelo ezijwayelekile ze-Straight cut slots ezeCold Production kanye nemithombo evundlile ye-CBM ngaphezu kwemithombo yokujova ye-SAGD.

Izikhala ze-Keystone ezithungwe--zigaywe banzi ngaphakathi kwepayipi futhi ziyazihlanza ukuze zisize ukuvimbela ukuxhuma.Incane endaweni yomugqa futhi ikhula ngobubanzi ngaphakathi, ivumela isihlabathi esingenayo sidlule kalula ezindaweni ngaphandle kokuxhuma.

| Ipayipi le-API Casing | ID | Ubude | Slot Ubude | Isikhala No. | Ububanzi besikhala | Isikhala | Isihlungi Esivumelekile | Ubukhulu. | ||

| Ukucaciswa mm | Ubukhulu | Ngesisindo | ||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

| 88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

| 101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

| 127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

| 139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

| 9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

| 168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

| 177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

| 9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

| Ubukhulu bepayipi elikhanyayo (ngaphakathi) | I-OD(mm) | Ubukhulu bodonga(mm) | I-ID (mm) | Inombolo yokuthunga yendilinga ngayinye | Ububanzi besikhala(mm) | Ubude besikhala (mm) | Ubude(mm) |

| 2-3/8″ | 60.3 | 4.83 | 50.64 | 12-18 | 0.2~0.8 | 45-100 | 1000 ~ 12000 |

| 2-7/8″ | 73 | 5.51 | 61.98 | 20~24 | 45-100 | ||

| 3-1/2″ | 88.9 | 6.45 | 76 | 24-28 | 45-100 | ||

| 4″ | 101.6 | 6.65 | 88.29 | 24-30 | 45-100 | ||

| 4-1/2″ | 114.3 | 5.69 | 102.92 | 24-30 | 45-100 | ||

| 6.35 | 101.6 | 45-100 | |||||

| 7.37 | 99.57 | 45-100 | |||||

| 8.56 | 97.18 | 45-100 | |||||

| 5″ | 127 | 5.59 | 115.82 | 28-36 | 0.25~0.8 | 45-100 | |

| 6.43 | 114.15 | 45-100 | |||||

| 7.52 | 111.96 | 45-100 | |||||

| 9.19 | 108.61 | 45-100 | |||||

| 5-1/2″ | 139.7 | 6.2 | 127.3 | 30-38 | 45-100 | ||

| 6.99 | 125.73 | 45-100 | |||||

| 7.72 | 124.26 | 45-100 | |||||

| 9.17 | 121.36 | 45-100 | |||||

| 10.54 | 118.62 | 45-100 | |||||

| 7″ | 177.8 | 6.91 | 163.98 | 36-50 | 45-100 | ||

| 8.05 | 161.7 | 45-100 | |||||

| 9.19 | 159.41 | 45-100 | |||||

| 10.36 | 157.07 | 45-100 |

1. Ipayipi lethu elinezimbobo lisebenzisa i-J55/K55/N80 casing kanye namashubhu asezingeni le-API, anamandla Aphezulu, akulula ukuwohloka.

2. Unqenqema lwe-slot luqondile, lubushelelezi, ngaphandle kwama-burrs, futhi i-slot iyafana.

3. Ipayipi enezimbobo ifaneleka kahle esihlabathini, lapho ububanzi besihlabathi bungaphezu kuka-0.3mm.

4. I-slot ingaba yi-longitudinal ne-transverse, isigaba se-slot singaba izinhlobo ezihambisanayo kanye ne-trapezoidal, enendawo evulekile ebanzi.

5. Ipayipi lesikrini esinezikhala ezinobubanzi obukhulu bangaphakathi.

I-API Spec 5CT-Ukucaciswa kwe-5CT/ISO 11960, Ukucaciswa kwe-Casing and Tubing, i-Eighth Edition, i-Petroleum negesi yemvelo-Amapayipi ensimbi azosetshenziswa njenge-casing noma ishubhu emithonjeni

| Okujwayelekile | Ibanga | Ukwakhiwa kwamakhemikhali (()) | |||||||||

| I-API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34-0.39 | 0.20-0.35 | 1.25-1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34-0.38 | 0.20-0.35 | 1.45-1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11-0.16 | |

| L80 | 0.15-0.22 | ≤1.00 | 0.25-1.00 | ≤0.020 | ≤0.010 | 12.0-14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26-0.395 | 0.17-0.37 | 0.40-0.70 | ≤0.020 | ≤0.010 | 0.80-1.10 | ≤0.20 | ≤0.20 | 0.15-0.25 | ≤0.08 | |

Izakhiwo Zemishini

| Ibanga | Uhlobo | Ubude obuphelele ngaphansi komthwalo (%) | Amandla esivuno (min) | Amandla okukhiqiza (ubukhulu) | Amandla e-tensile min Mpa | I-Hardness Max (HRC) | Ukuqina okuphezulu(HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Kr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Kr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | Konke | 0.65 | 862 | 1034 | 931 | - | - |

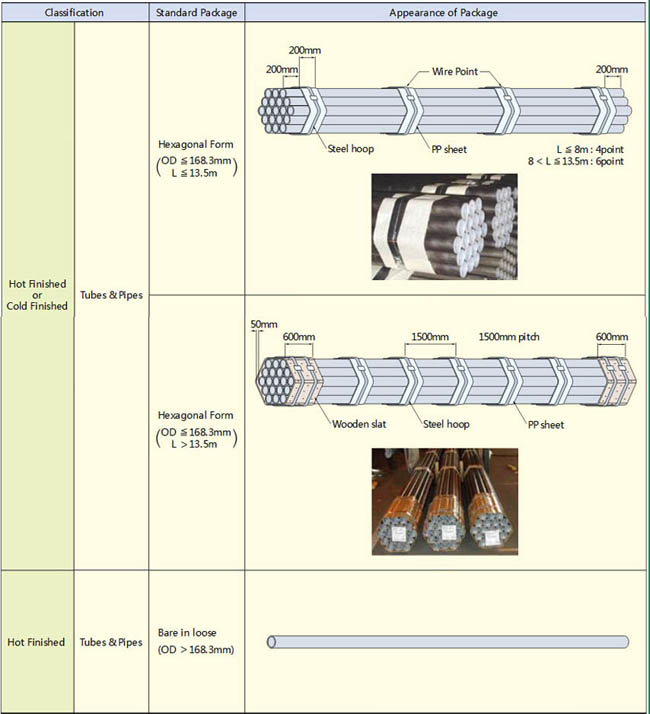

I-Single nesikhwama se-bubble bese iba sebhokisini lamapulangwe (isitifiketi sokufuthwa).Icala ngalinye limakwe ngokucacile ngokuthi:

1. Igama nophawu lokuhlonza lomkhiqizi-HuaDong Brand

2. Inombolo yeqoqo

3. Usuku lomkhiqizi

4. Indaba

5. Ukushisa okuphephile nezinga lokushisa lesicelo