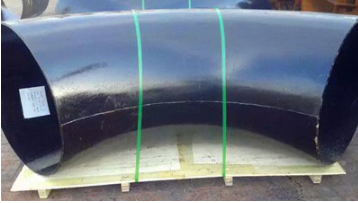

Indololwane

Inqubo Yokukhiqiza Indololwane Engenamthungo (Ukugoba Ukushisa Nokugoba Okubandayo)

Enye yezindlela ezivame kakhulu zokukhiqiza izindololwane isebenzisa ukugoba kwe-mandrel eshisayo kusuka kumapayipi ensimbi aqondile.Ngemuva kokushisa ipayipi yensimbi ekushiseni okuphakeme, ipayipi iqhutshwa, yandiswa, igobe ngamathuluzi angaphakathi we-mandrel isinyathelo ngesinyathelo.Ukusebenzisa ukugoba kwe-mandrel eshisayo kungenza usayizi obanzi wendololwane engenamthungo.Izici ze-mandrel ukugoba zincike kakhulu ekubunjweni okuhlanganisiwe nobukhulu be-mandrel.Izinzuzo zokusebenzisa izindololwane ezigobile ezishisayo zifaka ukuchezuka kogqinsi oluncane kanye nerediyasi yokugoba enamandla kunolunye uhlobo lwendlela yokugoba.Khonamanjalo, ukusebenzisa ukugoba esikhundleni sokugoba okwakhelwe ngaphambili kunciphisa kakhulu inani lamashisela adingekayo.Lokhu kunciphisa inani lomsebenzi odingekayo futhi kwandisa ikhwalithi nokusebenziseka kwamapayipi.Nokho, ukugoba okubandayo kuyinqubo yokugoba ipayipi lensimbi eliqondile emazingeni okushisa avamile emshinini ogobayo.Ukugoba okubandayo kulungele amapayipi anobubanzi obungaphandle obusuka ku-17.0 kuye ku-219.1 mm, nogqinsi olusuka ku-2.0 kuya ku-28.0 mm.Irediyasi yokugoba enconyiwe ingu-2.5 x Do.Ngokuvamile endaweni egobayo engu-40D.Ngokusebenzisa ukugoba okubandayo, singathola izindololwane ezincane zerediyasi, kodwa sidinga ukupakisha izinto zangaphakathi ngesihlabathi ukuze sigweme ukushwabana.Ukugoba okubandayo kuyindlela yokugoba esheshayo nengabizi.Kuyinketho yokuncintisana yokwenza amapayipi nezingxenye zomshini.

Inqubo Yokukhiqiza Indololwane Eshiselwe (Encane & Enkulu)

Izindololwane ezishiselwe zenziwe ngamapuleti ensimbi, ngakho-ke akuzona izindololwane zensimbi ezingenamthungo.Sebenzisa isikhunta bese ucindezela i-steel plate ukuze ifane nendololwane, bese ushisela umthungo ukuze ube indololwane yensimbi yokuqeda.Yindlela endala yokukhiqiza izindololwane.Eminyakeni yamuva izindololwane ezincane zicishe zenziwe ngamapayipi ensimbi manje.Ezindololwaneni zikasayizi omkhulu, isibonelo, kunzima kakhulu ukukhiqiza izindololwane ezingaphezu kuka-36” OD ngamapayipi ensimbi .Ngakho-ke kuvame ukwakhiwa ngamapuleti ensimbi, ukucindezela ipuleti libe uhafu wendololwane, bese kushiselwa amahhafu amabili ndawonye.Njengoba izindololwane zishiselwe emzimbeni wayo , ukuhlolwa kwejoyinti le-welding kuyadingeka.Ngokuvamile sisebenzisa ukuhlolwa kwe-X-Ray njenge-NDT.

| Usayizi wepayipi lokuzisholo | Ngaphandle Ububanzi | Maphakathi kuya ekugcineni | Maphakathi nendawo | Buyela Ebusweni | ||||||

| 45° Izindololwane | 90° Izindololwane | 180°Buyela | ||||||||

| H | F | P | K | |||||||

| DN | INCH | Uchungechunge A | Uchungechunge B | LR | LR | SR | LR | SR | LR | SR |

| 15 | 1/2 | 21.3 | 18 | 16 | 38 | - | 76 | - | 48 | - |

| 20 | 3/4 | 26.9 | 25 | 16 | 38 | - | 76 | - | 51 | - |

| 25 | 1 | 33.7 | 32 | 16 | 38 | 25 | 76 | 51 | 56 | 41 |

| 32 | 11/4 | 42.4 | 38 | 20 | 48 | 32 | 95 | 64 | 70 | 52 |

| 40 | 11/2 | 48.3 | 45 | 24 | 57 | 38 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 57 | 32 | 76 | 51 | 152 | 102 | 106 | 81 |

| 65 | 21/2 | 76.1(73) | 76 | 40 | 95 | 64 | 191 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 89 | 47 | 114 | 76 | 229 | 152 | 159 | 121 |

| 90 | 31/2 | 101.6 | - | 55 | 133 | 89 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 108 | 63 | 152 | 102 | 305 | 203 | 210 | 159 |

| 125 | 5 | 139.7 | 133 | 79 | 190 | 127 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 159 | 95 | 229 | 152 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 219 | 126 | 305 | 203 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273.0 | 273 | 158 | 381 | 254 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.9 | 325 | 189 | 457 | 305 | 914 | 610 | 619 | 467 |

| 350 | 14 | 355.6 | 377 | 221 | 533 | 356 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 426 | 253 | 610 | 406 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457.2 | 478 | 284 | 686 | 457 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508.0 | 529 | 316 | 762 | 508 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559 | - | 347 | 838 | 559 | Qaphela: | |||

| 600 | 24 | 610 | 630 | 379 | 914 | 610 | ||||

| 650 | 26 | 660 | - | 410 | 991 | 660 | ||||

| 700 | 28 | 711 | 720 | 442 | 1067 | 711 | ||||

| 750 | 30 | 762 | - | 473 | 1143 | 762 | ||||

| 800 | 32 | 813 | 820 | 505 | 1219 | 813 | ||||

| 850 | 34 | 864 | - | 537 | 1295 | 864 | ||||

| 900 | 36 | 914 | 920 | 568 | 1372 | 914 | ||||

| 950 | 38 | 965 | - | 600 | 1448 | 965 | ||||

| 1000 | 40 | 1016 | 1020 | 631 | 1524 | 1016 | ||||

| 1050 | 42 | 1067 | - | 663 | 1600 | 1067 | ||||

| 1100 | 44 | 1118 | 1120 | 694 | 1676 | 1118 | ||||

| 1150 | 46 | 1168 | - | 726 | 1753 | 1168 | ||||

| 1200 | 48 | 1220 | 1220 | 758 | 1829 | 1219 | ||||

I-ASTM A234

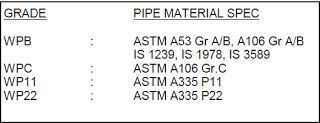

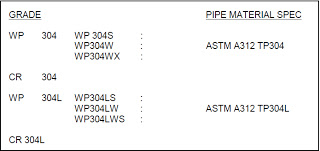

Lokhu kucaciswa kuhlanganisa ukufakwa kwensimbi eyenziwe nge-carbon steel & alloy steel yokwakhiwa okungenamthungo nokushiselwe.Ngaphandle uma kucaciswe ukwakhiwa okungenamthungo noma okushiselwe ngokulandelana, kungase kuhlinzekwe ngokukhetha komhlinzeki.Zonke izinsimbi zokwakha ezishiselwe ngokwaleli zinga zihlinzekwa nge-radiography engu-100%.Ngaphansi kwe-ASTM A234, amamaki ambalwa ayatholakala kuye ngokwakheka kwamakhemikhali.Ukukhethwa kuzoncika ezintweni zamapayipi ezixhunywe kulokhu kufakwa.

| Izidingo ze-Tensile | I-WPB | I-WPC, WP11CL2 | I-WP11CL1 | I-WP11CL3 |

| Amandla Okuqina, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% offset noma 0.5% extension-under-load) | [415-585] | [485-655] | [415-585] | [520-690] |

| Isivuno Amandla, min, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |

Amanye amabanga atholakala ngaphansi kwalokhu kucaciswa kanye nokucaciswa kwempahla yamapayipi axhunyiwe ahlelwe ngezansi:

I-ASTM A403

Lokhu kucaciswa kuhlanganisa amakilasi amabili ajwayelekile, i-WP ne-CR, yokufakwa kwensimbi engagqwali eyenziwe nge-austenitic yokwakhiwa okungenamthungo nokushiselwe.

Ukufakwa kwe-WP Yekilasi kukhiqizwa ngokwezidingo ze-ASME B16.9 & ASME B16.28 futhi kuhlukaniswe ngezigaba ezintathu kanje:

- I-WP - Kwenziwe ngomkhiqizo ongenamthungo ngendlela yokukhiqiza engenamthungo.

- I-WP - W Lokhu kufakwa kuqukethe ama-welds kanye nawo wonke ama-welds enziwe ngumkhiqizi ofanelekayo okuhlanganisa ukuqala kwepayipi uma ipayipi ihlanganiswe nokwengezwa kwezinto zokugcwalisa i-radiographed.Kodwa-ke, ayikho i-radiography eyenzelwe ukushiselwa kwepayipi lokuqala uma ipayipi lishiselwe ngaphandle kokwengezwa kwezinto zokugcwalisa.

- I-WP-WX Lezi zifakelo ziqukethe izinto ezishiselelwayo futhi zonke izinto ezishiselwayo noma ngabe zenziwe ngumkhiqizi ofanelekayo noma umkhiqizi wezinto eziqalayo zenziwe nge-radiograph.

Ukufakwa kwe-CR kwekilasi kukhiqizwa ngokwezidingo ze-MSS-SP-43 futhi akudingi ukuhlolwa okungonakali.

Ngaphansi kwe-ASTM A403 amabanga ambalwa ayatholakala kuye ngokwakheka kwamakhemikhali.Ukukhethwa kuzoncika ezintweni zamapayipi ezixhunywe kulokhu kufakwa.Amanye amabanga atholakala ngaphansi kwalokhu kucaciswa kanye nokucaciswa kwempahla yamapayipi axhunyiwe ahlelwe ngezansi:

I-ASTM A420

Lokhu kucaciswa kuhlanganisa insimbi eyenziwe nge-carbon steel ne-alloy steel yokwakhiwa okungenamthungo nokushiselwe okuhloselwe ukusetshenziswa emazingeni okushisa aphansi.Ihlanganisa amabanga amane i-WPL6, WPL9, WPL3 & WPL8 kuye ngokwakheka kwamakhemikhali.Ukufakwa kwe-WPL6 kunomthelela ovivinyweni lokushisa - 50° C, WPL9 ku -75° C, WPL3 ku -100° C kanye ne-WPL8 ku -195° C.

Izilinganiso zokucindezela ezivumelekile zokufakwa zingase zibalwe njengamapayipi angenamthungo aqondile ngokuvumelana nemithetho esungulwe esigabeni esisebenzayo se-ASME B31.3.

Ubukhulu bodonga lwamapayipi kanye nohlobo lwempahla kuzoba yilokho okufakwayo okuyalelwe ukuthi kusetshenziswe ngakho, ubunikazi bawo ezintweni ezifakelwe esikhundleni sezimpawu zokulinganisa ingcindezi.

| Insimbi No. | Uhlobo | Ukwakheka kwamakhemikhali | ||||||||||||

| C | Si | S | P | Mn | Cr | Ni | Mo | Okunye | ób | ós | δ5 | HB | ||

| I-WPL6 | 0.3 | 0.15-0.3 | 0.04 | 0.035 | 0.6-1.35 | 0.3 | 0.4 | 0.12 | Cb:0.02;V:0.08 | 415-585 | 240 | 22 | ||

| I-WPL9 | 0.2 | 0.03 | 0.03 | 0.4-1.06 | 1.6-2.24 | 435-610 | 315 | 20 | ||||||

| I-WPL3 | 0.2 | 0.13-0.37 | 0.05 | 0.05 | 0.31-0.64 | 3.2-3.8 | 450-620 | 240 | 22 | |||||

| I-WPL8 | 0.13 | 0.13-0.37 | 0.03 | 0.03 | 0.9 | 8.4-9.6 | 690-865 | 515 | 16 | |||||

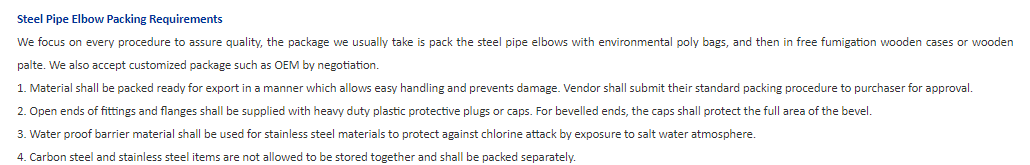

Ukugcoba Ngamafutha Okulula, Ukupenda Okumnyama, Ukugalela, I-PE /3PE I-Anti-corrosion Coating

Ipakishwe eWood Cabins/Wood Tray