Ipayipi le-Titanium / Ipayipi

Ishubhu ye-Titanium engenamthungo icutshungulwa ngokuhlukana kwe-titanium ingot, idlulele ku-titanium tube billet.Bese ukhiqiza amashubhu e-titanium ukuze abe usayizi ofanele ngochungechunge lwezinqubo ezifana nokugoqa okuningi, ukuhlanganisa, ukucosha, nobuchwepheshe bokugaya.

Ishubhu elishiselwe i-Titanium ngokukhetha ubukhulu obufanele bepuleti le-titanium eligoqiwe lekhwalithi ephezulu, ngemva kwenqubo yokwenza isicaba, ukusika nokugeza, bese kugoqwa ipuleti le-titanium libe yi-tubular, lishiswa ngayo yonke imishini yokushisela okuzenzakalelayo.Imishini yethu yokushisela esezingeni eliphezulu iqinisekise ikhwalithi yokushisela.Ekugcineni ukusiza ukukhiqiza izinga elihle kakhulu le-titanium tube.

I-Titanium tube engenamthungo

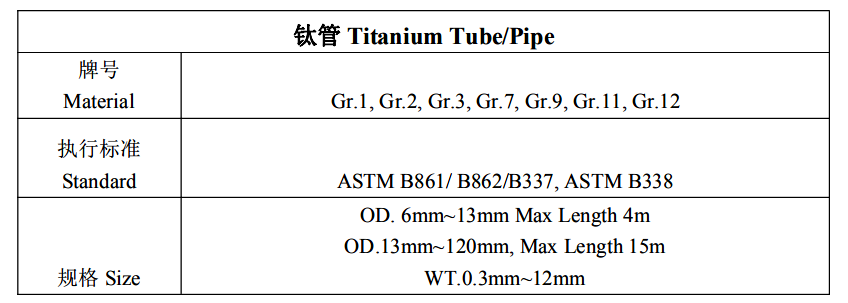

Ibanga: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 njll

Ububanzi bangaphandle: 3 ~ 110mm

Ubukhulu bodonga: 0.1 ~ 5.5mm

Ubude: ≤19000mm

I-Titanium weld tube

Ibanga: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 njll

Ububanzi bangaphandle: 10 ~ 1000mm

Ubukhulu bodonga: 0.5 ~ 5.5mm

Ubude: ≤19000mm

Gr5, Gr23 titanium alloy tube engenamthungo

Ububanzi bangaphandle: 20 ~ 110mm

Ubukhulu bodonga: 1 ~ 50mm

Ubude: ≤3000mm

Inqubo yokukhiqiza: I-Drilling, i-Hot Rolling

| IPHAyiphi LE-TITANIUM ELINGEMTHUNGO | ||||||||||

|

| I-S10 | S40 | S80 | |||||||

| Usayizi wepayipi | OD | Udonga | Ngaphakathi kweDiya. | lbs / ft | Udonga | Ngaphakathi kweDiya. | lbs / ft | Udonga | Ngaphakathi kweDiya. | lbs / ft |

| 1/8 | .405 | .049 | .307 | .1072 | .068 | .269 | .1408 | .095 | .215 | .1810 |

| 1/4 | .540 | .065 | .410 | .1897 | .088 | .364 | .2442 | .119 | .302 | .3079 |

| 3/8 | .675 | .065 | .545 | .2437 | .091 | .493 | .3266 | .126 | .423 | .4251 |

| 1/2 | .840 | .083 | .674 | .3861 | .109 | .622 | .4896 | .147 | .546 | .6260 |

| 3/4 | 1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 | .154 | .742 | .8479 |

| 1 | 1.315 | .109 | 1.097 | .8078 | .133 | 1.049 | .9660 | .179 | .957 | 1.2495 |

| 1-1/4 | 1.660 | .109 | 1.442 | 1.0389 | .140 | 1.380 | 1.3077 | .191 | 1.278 | 1.7242 |

| 1-1/2 | 1.900 | .109 | 1.681 | 1.1996 | .145 | 1.610 | 1.5637 | .200 | 1.500 | 2.0893 |

| 2 | 2.375 | .109 | 2.157 | 1.5178 | .154 | 2.067 | 2.1018 | .218 | 1.939 | 2.8895 |

| 2-1/2 | 2.875 | .120 | 2.635 | 2.0315 | .203 | 2.469 | 3.3331 | .276 | 2.323 | 4.4080 |

| 3 | 3.500 | .120 | 3.260 | 2.4924 | .216 | 3.068 | 4.3589 | .300 | 2.900 | 5.8992 |

| 3-1/2 | 4.000 | .120 | 3.760 | 2.8611 | .226 | 3.548 | 5.2412 | .318 | 3.364 | 7.1950 |

| 4 | 4.500 | .120 | 4.260 | 3.2298 | .237 | 4.026 | 6.2085 | .337 | 3.826 | 8.6210 |

| 5 | 5.563 | .134 | 5.295 | 4.4704 | .258 | 5.047 | 8.4106 | .375 | 4.813 | 11.9550 |

| 6 | 6.625 | .134 | 6.357 | 5.3449 | .280 | 6.065 | 10.917 | .432 | 5.761 | 16.440 |

| IPHAMBI ELISHISELWE I-TITANIUM | |||||||

|

| I-S10 | S40 | |||||

| Usayizi wepayipi | OD | Udonga | Ngaphakathi kweDiya. | lbs / ft | Udonga | Ngaphakathi kweDiya. | lbs / ft |

| 3/4 | .1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 |

| 1 | 1.315 | .109 | 1.097 | .8078 | .133 | 1.049 | .9660 |

| 1-1/4 | 1.660 | .109 | 1.442 | 1.0389 | .140 | 1.380 | 1.3077 |

| 1-1/2 | 1.900 | .109 | 1.681 | 1.1996 | .145 | 1.610 | 1.5637 |

| 2 | 2.375 | .109 | 2.157 | 1.5178 | .154 | 2.067 | 2.1018 |

| 2-1/2 | 2.875 | .120 | 2.635 | 2.0315 | .203 | 2.469 | 3.3331 |

| 3 | 3.500 | .120 | 3.260 | 2.4924 | .216 | 3.068 | 4.3589 |

| 3-1/2 | 4.000 | .120 | 3.760 | 2.8611 | .226 | 3.548 | 5.2412 |

| 4 | 4.500 | .120 | 4.260 | 3.2298 | .237 | 4.026 | 6.2085 |

| 5 | 5.563 | .134 | 5.295 | 4.4704 | .258 | 5.047 | 8.4106 |

| 6 | 6.625 | .134 | 6.357 | 5.3449 | .280 | 6.065 | 10.917 |

| 8 | 8.625 | .148 | 8.329 | 7.7095 | .322 | 7.981 | 16.429 |

| 10 | 10.750 | .165 | 10.420 | 10.732 | .365 | 10.020 | 23.293 |

| 12 | 12.750 | .180 | 12.390 | 13.904 | .375 | 12.000 | 28.517 |

| 14 | 14.000 | .188 | 13.624 | 15.956 | .375 | 13.250 | 31.397 |

| 16 | 16.000 | .188 | 15.624 | 18.267 | .375 | 15.250 | 36.006 |

| 18 | 18.000 | .188 | 17.624 | 20.577 | .375 | 17.250 | 40.615 |

| 20 | 20.000 | .218 | 19.564 | 26.500 | .375 | 19.250 | 45.223 |

| 24 | 24.000 | .250 | 23.500 | 36.486 | .375 | 23.250 | 54.441 |

I-ASTM B338 – 10e1 Ukucaciswa Okujwayelekile Kwe-Titanium Engenamthungo futhi Eshisiwe kanye ne-Titanium Alloy Tubes yama-Condensers nama-Heat Exchanger

I-ASTM B862 – 09 Ukucaciswa Okujwayelekile kwe-Titanium ne-Titanium Alloy Welded Pipe

I-ASTM B861 – 10 Ukucaciswa Okujwayelekile kwe-Titanium ne-Titanium Alloy Seamless Pipe, i-ASTM B337

| I-Titanium Tube / Ipayipi | Igama lomkhiqizo | Ibanga | Ukucaciswa(mm) | Okujwayelekile |

| I-Seamless Tube | Gr.1 Gr.2 Gr.7 Gr.9 Gr.12

| I-OD(3-114)×THK(0.5-10) ×≤ ubude 12000 | I-ASTM B337 ASTM B338 I-ASTM B861 | |

| Ipayipi lokushisela | Gr.1 Gr.2 Gr.7 Gr.12 | ≥OD133 | I-ASTM B862 | |

| Ishubhu(Russia) | I-BT1-0 | I-OD(3-114)×THK(0.5-10) ×≤ ubude 12000 | I-GOST22879 | |

Ukwakheka kwamakhemikhali

| Ibanga | Ukwakheka kwamakhemikhali, iphesenti lesisindo (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ezinye Izinto Ubukhulu.ngamunye | Ezinye Izinto Ubukhulu.ingqikithi | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5-4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12-0.25 | - | 0.12-0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5-3.5 | 2.0-3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12-0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6-0.9 | 0.2-0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04–0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5-6.5 | 3.5-4.5 | - | - | - | - | 0.1 | 0.1 |

Izici ezingokomzimba

| Ibanga | Izici ezingokomzimba | ||||

| Amandla aqinile Okuncane | Amandla esivuno Ubuncane (0.2%,i-offset) | Ubude ku-2in noma 50mm Ubuncane (%) | |||

| ksi | I-MPa | ksi | I-MPa | ||

| Gr1 | 35 | 240 | 20 | 138 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 20 |

| Gr5 | 130 | 895 | 120 | 828 | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | 10 |