1: Ukudweba (i-black coating)

Indwangu ebrasive yokuhlanza ipayipi lensimbi ukuze kukhishwe ukugqwala, xubha into evimbela ukugqwala ukuze ulinde upende ukuthi wome ngokwemvelo, bese uxubha ijazi lokuqala elivimbela ukugqwala,ngemva kokoma ngokwemvelo, xubha futhi ijazi elilwa nokugqwala.

2:Beveling (ukuphela kokwelashwa)

Ngokuvamile, i-beveling iwukuqinisekisa ikhwalithi ye-welding. I-welding ye-workpiece iyadingeka ngaphambi kwe-welding. Ukuze i-welding iqine, i-chamfer igaywa emaphethelweni epuleti.

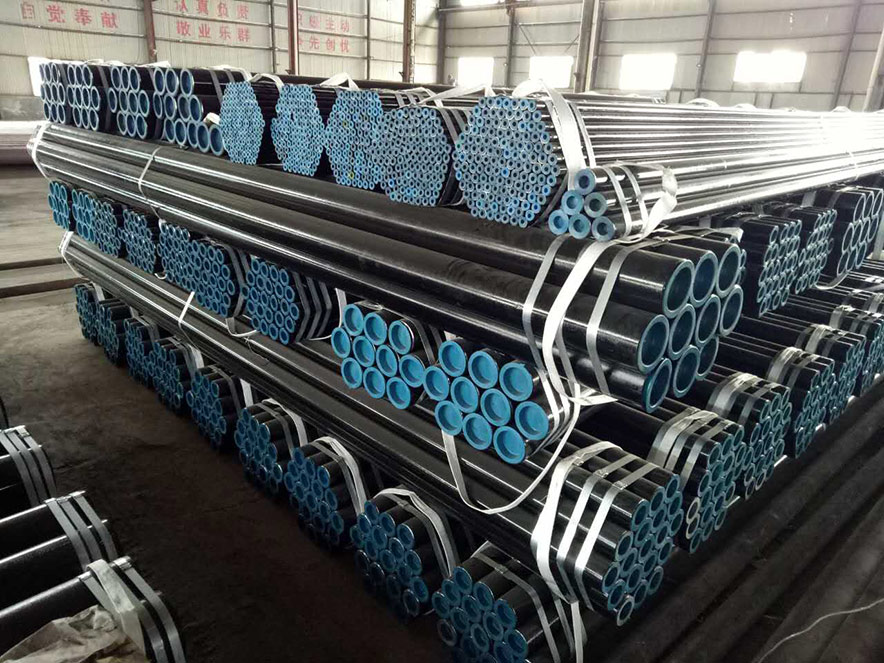

3:Ukupakisha (ibhande lensimbi)

Ukubhalisa ibhande lensimbi: Inqwaba efanayo yamapayipi ensimbi izoba yizinga lensimbi elifanayo, izinga lensimbi, kanye nepayipi lensimbi lokucaciswa okufanayo. Uma ingaphansi kwenqwaba eyodwa, izohlanganiswa ibe izinyanda ezincane. Ngokwesicelo sekhasimende, isivikelo sepulasitiki sinamathiselwe ekugcineni kwepayipi ngalinye lensimbi eliyisicaba.

4:Ezokuthutha

(1) Izinto zokuhamba zamaloli: Indawo engaphansi kwekhompathimenti ibekwe kahle nezindawo zokulala namaphedi enjoloba avikelayo. Faka izithiyo zokuzivikela ekubhinceni ipayipi lensimbi ukuze uvimbele ukulimala ebusweni bepayipi lensimbi, gwema ukungqubuzana okuqondile phakathi kwepayipi lensimbi nemoto, ukungqubuzana, kanye nesiphithiphithi sangaphambili nangemuva.

(2) Ukuthuthwa kwesitsha: Faka izinto ezifanele zokubhafa enqoleni ukuze uvimbele ipayipi lensimbi ukuthi lingagingqiki futhi linyakaze, ugweme umthelela wokuphela kwepayipi, futhi ungaphuhli into ephakathi nendawo ngendle noma izinto zamakhemikhali.