Ukushisa Ex-Changer

Ayini ama-Heat Exchanger?

Igama elithi "i-heat exchanger" lisetshenziselwa ukuchaza idivayisi eyenza ukudluliselwa kokushisa kusuka kolunye uketshezi kuya kolunye ngaphandle kokuhlanganisa kokubili. Ihlanganisa imigudu noma izindlela ezimbili ezihlukene, eyodwa eyoketshezi olushisayo neyodwa eyoketshezi olubandayo, ehlala ehlukene ngenkathi ishintshanisa ukushisa. Umsebenzi oyinhloko wesishintshi sokushisa uwukuthuthukisa ukusebenza kahle kwamandla ngokusebenzisa ukushisa okulahlwayo, ukonga izinsiza, nokunciphisa izindleko zokusebenza.

Izinhlobo Ezivamile Zokushintsha Ukushisa

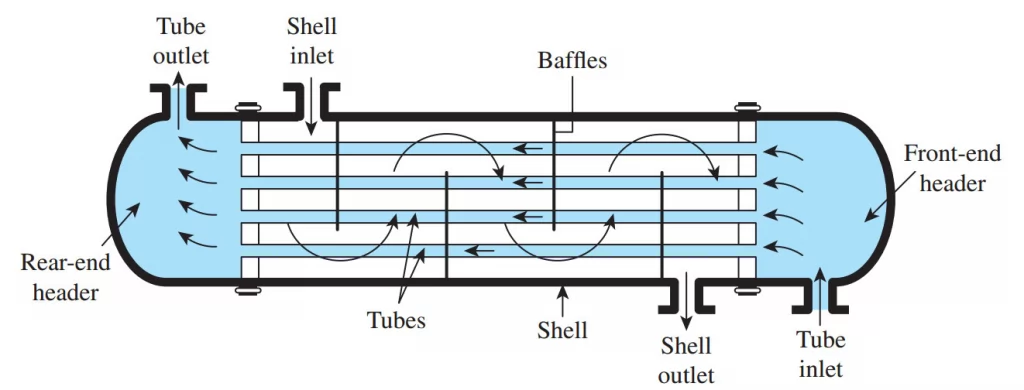

Izishintshi zokushisa zamagobolondo namashubhu:Lezi izinhlobo ezivame kakhulu zokushintshisana kokushisa ezisetshenziswa ezinhlelweni ze-HVAC zezentengiselwano. Aqukethe uchungechunge lwamashubhu avalelwe egobolondweni. Uketshezi olushisayo lugeleza ngamashubhu kuyilapho uketshezi olubandayo luzungeza amashubhu ngaphakathi kwegobolondo, okuvumela ukushintshaniswa kokushisa okuphumelelayo.

Izishintshi zokushisa zamapuleti:Izishintshisi zokushisa zamapuleti zisebenzisa inqwaba yamapuleti ensimbi anezindawo eziphakeme nezicindezelekile ezishintshanayo. Uketshezi olushisayo nolubandayo lugeleza eziteshini ezihlukene ezidalwe izikhala phakathi kwamapuleti, okwandisa ukudluliswa kokushisa ngenxa yendawo enkulu.

Izishintshi zokushisa zomoya ziye emoyeni:Okwaziwa nangokuthi amayunithi okubuyisela ukushisa, lezi zishintshisi zokushisa zidlulisa ukushisa phakathi kokukhipha futhi zinikeze ngemifudlana yomoya. Asusa ukushisa emoyeni omdala futhi akudlulisele emoyeni omusha, anciphise ukusetshenziswa kwamandla ngokufaka kuqala umoya opholile.

Kuyini Ukusetshenziswa Kwezimboni KweShell kanye Ne-Tube Heat Exchanger?

Ukusetshenziswa kwezimboni kwamagobolondo namashubhu okushintshanisa ukushisa, asetshenziswa kumakhemikhali, ukudla, uwoyela negesi nezinye izinkambu, kusabalele. Ngokuvamile zisetshenziswa ezimbonini ezihlukahlukene zokudlulisa ukushisa phakathi koketshezi olubili ngaphandle kokuxhumana okuqondile. Ezinye zezimboni ezibalulekile zegobolondo kanye nezicelo zokushintsha ukushisa kweshubhu zifaka:

Izinqubo zokushisisa nokupholisa ezitshalweni zamakhemikhali

Ukujiya kanye nokuhwamuka kwemisebenzi ezindaweni zokuhluza

Amasistimu okubuyisela ukushisa ezindaweni zokuphehla amandla

Amasistimu e-HVAC ezakhiweni zezentengiselwano nezindawo zokuhlala

Izinhlelo zokuqandisa ezindaweni zokucubungula ukudla

Ukuphathwa okushisayo ezindaweni zokukhiqiza uwoyela negesi

Sekukonke, izishintshisi zokushisa zegobolondo namashubhu zidlala indima ebalulekile ekwandiseni ukusebenza kahle kokushisa kanye nokugcina izinga lokushisa lilawulwa kuzo zonke izinqubo zezimboni.

Zingaki Izinhlobo Zegobolondo ne-Tube Heat Exchanger?

Empeleni, kunezinhlobo ezintathu eziyinhloko zamagobolondo namashubhu okushintshanisa ukushisa okuvame ukusetshenziswa:

1. I-Fixed Tube Sheet Exchanger (i-L, M, kanye Nezihloko zasemuva zohlobo luka-N)

Kulo mklamo, ishidi le-tube lihlanganiswe negobolondo, okuholela ekwakhiweni okulula nokonga. Nakuba amashubhu angahlanzwa ngomshini noma ngamakhemikhali, izindawo ezingaphandle zamashubhu ngokuvamile azifinyeleleki ngaphandle kokuhlanza ngamakhemikhali. Izivunguvungu zokunwetshwa zingadingeka ukuze kuhlangatshezwane nomehluko omkhulu wokushisa phakathi kwegobolondo nezinto zeshubhu, kodwa zingaba umthombo wobuthakathaka nokwehluleka.

2. U-Tube Exchangers

Ku-exchanger ye-U-Tube, izinhlobo zeheda yangaphambili zingahluka, futhi unhlokweni ongemuva ngokuvamile uwuHlobo lwe-M. Ama-U-tubes avumela ukwanda okushisayo okungenamkhawulo, futhi inqwaba yeshubhu ingasuswa ukuze ihlanzwe. Kodwa-ke, ukuhlanza kwangaphakathi kwamashubhu ngezindlela zemishini kunzima, okwenza lolu hlobo lufaneleke kuphela izinhlelo zokusebenza lapho uketshezi oluseceleni kwe-tube luhlanzekile.

3. I-Floating Head Exchanger (P, S, T, no-W Uhlobo Lwezihloko Ezingemuva)

Kulolu hlobo lokushintshisana, i-tubesheet ekugcineni kwekhanda elingemuva alishiselwe egobolondweni kodwa livunyelwe ukunyakaza noma ukuntanta. I-tubesheet ekupheleni kwekhanda elingaphambili linobubanzi obukhulu kunegobolondo futhi livalwe ngokufana nomklamo we-tubesheet ongashintshi.

Ukwandiswa kwe-thermal kungenziwa, futhi i-tube bundle ingasuswa ukuze ihlanzwe. I-S-Type Rear Head iyona ethandwa kakhulu unhlokweni wangemuva. Izishintshi zekhanda ezintantayo zifanele amazinga okushisa aphezulu nezingcindezi kodwa ngokuvamile zibiza kakhulu uma ziqhathaniswa nezishintshisi zama-tubesheet ezingashintshi.

Njengomphakeli wamapayipi ochwepheshe, i-Hnssd.com ingahlinzeka Ngezishintshi Zokushisa Ngokwezifiso. Uma udinga ulwazi olwengeziwe mayelana nemikhiqizo yethu, sicela ngomusa ukuthi usithinte:sales@hnssd.com

Izingxenye zegobolondo nesishintshi sokushisa seshubhu zingahlukaniswa zibe izingxenye ezilandelayo:

1. Igobolondo

Igobolondo liyingxenye engaphandle kakhulu yesishintshi sokushisa ephethe inqwaba yeshubhu. Ivamise ukuba yisitsha esiyicylindrical esakhiwe ngensimbi noma ezinye izinto ezifanele

2. Amashubhu noma i-Tube Bundle

Iqoqo lamashubhu ahambisanayo agijima ngobude begobolondo lenza inqwaba yamashubhu. Ngokuya ngokusetshenziswa okuqondile, amashubhu angakhiwa ngezinto ezahlukene, njengensimbi engagqwali, ithusi, noma i-titanium. Ububanzi nobukhulu bamashubhu nakho kuyimingcele ebalulekile yokuklama.

3. Amashidi e-Tube

Amashidi amashubhu angamashidi aqinile asebenza njengesithiyo phakathi kwenqwaba yeshubhu negobolondo. Ngokuvamile zakhiwe kusetshenziswa insimbi futhi zihlanganiswa negobolondo ukuze kuqinisekiswe ukuvala okuqinile nokungavuzi. Amashubhu afakwa ngezimbobo emashidini amashubhu futhi anganwetshwa noma ashiselwe endaweni.

4. Iziphazamiso

Ama-Baffles amapuleti noma izinduku ezibekwe ngaphakathi kwegobolondo ukuze kulawuleke ukuhamba koketshezi ezungeza inqwaba yeshubhu. Lokhu kungaba yi-longitudinal noma ukuphambana ngomumo futhi kuhloselwe ukuthuthukisa ukusebenza kahle kokudluliswa kokushisa.

5. Imilomo yokungenisa nokuphumayo

Imibhobho yokungena neyokuphuma isebenza njengezindawo zokungena nokuphuma kuketshezi kusishintshisi sokushisa. Lokhu kuxhumana kuvame ukubekwa ezindaweni ezihlukene zegobolondo futhi kunamathiselwe kumashubhu kanye negobolondo kusetshenziswa ama-flange noma ezinye izinhlobo zokufakwa.

6. Ukwandisa Amalunga

Amajoyinti okunweba ayizixhumi ezivumelana nezimo ezivumela ukunwetshwa nokufinyela okushisayo kwenqwaba yeshubhu. Ngokuvamile atholakala endaweni yokungena nasekuphumeni kwesishintshisi sokushisa, lawa majoyinti akhiwa kusetshenziswa imibhobho yensimbi noma ezinye izinto eziguquguqukayo.

7. Izakhiwo Zokusekela

Izakhiwo zokusekela zibamba izishintshi zokushisa endaweni, ziqinisekisa isisekelo esizinzile. Izakhiwo zokusekela zingaba zesikhashana noma zibe unomphela futhi zingase zenziwe ngensimbi noma ezinye izinto.

Igobolondo kanye ne-tube geometric terminology

| 1 | Inhloko Enganyakazi (Phambili)—Ishaneli | 20 | I-Slip-on Backing Flange |

| 2 | Ikhanda Elimisiwe (Phambili)—Bonnet | 21 | Isiketi se-Tubesheet esintantayo |

| 3 | I-Stationary (Front) Head Flange | 22 | Isiketi se-Tubesheet esintantayo |

| 4 | Ikhava yesiteshi | 23 | Ukupakisha Ibhokisi Flange |

| 5 | Imbobo Yekhanda Enganyakazi | 24 | Ukupakisha |

| 6 | I-Tubesheet enganyakazi | 25 | Ukupakisha Indandatho yomlandeli |

| 7 | Amashubhu | 26 | I-Lantern Ring |

| 8 | Igobolondo | 27 | Tie Rods and Spacers |

| 9 | Ikhava yeShell | 28 | Ama-Baffles Aguquguqukayo noma Amapuleti Okusekelwa |

| 10 | I-Shell Flange-Stationary Head End | 29 | I-Impingement Baffle noma Ipuleti |

| 11 | I-Shell Flange-Ikhanda Elingemuva Eliphethe | 30 | I-Longitudinal Baffle |

| 12 | Igobolondo Nozzle | 31 | Dlula Ukuhlukanisa |

| 13 | I-Shell Cover Flange | 32 | Ukuxhumana kwe-Vent |

| 14 | Ukunwetshwa Okuhlangene | 33 | Khipha Ukuxhumana |

| 15 | I-Tubesheet elintantayo | 34 | Uxhumano Lwezinsimbi |

| 16 | Ikhava Yekhanda Elintantayo | 35 | Sekela Saddle |

| 17 | I-Floating Head Flange | 36 | I-Lifting Lug |

| 18 | Idivayisi Esekela Ikhanda Elintantayo | 37 | Ubakaki Wokusekela |

| 19 | Hlukanisa indandatho ye-Shear |

Isakhiwo sobubanzi beshubhu kanye nephimbo

Amashubhu angase abe nobubanzi ukusuka ku-12.7 mm (0.5 in) kuya ku-50.8 mm (2 in), kodwa u-19.05 mm (0.75 in) no-25.4 mm (1 in) yiwona osayizi abavame kakhulu. Amashubhu abekwe ngamaphethini angunxantathu noma ayisikwele kumashidi amashubhu.

Izakhiwo zesikwele ziyadingeka lapho kudingekile ukufika endaweni ye-tube yokuhlanza ngomshini. Ukuhlelwa kwe-triangular kuvumela amashubhu amaningi endaweni enikeziwe. I-tube pitch iyibanga elifushane ukusuka maphakathi kuya maphakathi phakathi kwamashubhu. Isikhala seshubhu sinikezwa isilinganiso se-tube pitch/tube diameter, okuvamise ukuba ngu-1.25 noma 1.33. Njengoba ukwakheka kwesikwele kusetshenziselwa izinjongo zokuhlanza, igebe elincane lika-6.35 mm (0.25 in) livunyelwe phakathi kwamashubhu.

Izinhlobo ze-Baffle

Ama-Baffles afakwe ohlangothini lwegobolondo ukuze anikeze izinga eliphezulu lokudlulisa ukushisa ngenxa yokwanda kwesiyaluyalu kanye nokusekela amashubhu ngaleyo ndlela kuncishiswe ithuba lokulimala ngenxa yokudlidliza. Kunezinhlobo eziningi ezahlukene ze-baffle, ezisekela amashubhu futhi zikhuthaze ukugeleza kuwo wonke amashubhu.

I-Single Segmental (lokhu kuvame kakhulu),

I-Double Segmental (lokhu kusetshenziselwa ukuthola i-shellside velocity ephansi kanye nokwehla kwengcindezi),

I-Disc kanye ne-Doughnut.

Ibanga eliphakathi nendawo ukuya maphakathi phakathi kwama-baffle libizwa ngokuthi i-baffle-pitch futhi lokhu kungalungiswa ukuze kuhluke isivinini sokugeleza. Empeleni iphimbo le-baffle ngokuvamile alilikhulu kunebanga elilingana nobubanzi bangaphakathi begobolondo noma lisondele kunebanga elilingana nengxenye yesihlanu yobubanzi noma 50.8 mm (2 in) kuye ngokuthi yikuphi okukhulu. Ukuze kuvunyelwe uketshezi ukuthi lugeleze luye emuva naphambili phakathi kwamashubhu ingxenye ye-baffle iyasikwa. Ukuphakama kwale ngxenye kubizwa ngokuthi i-baffle-cut futhi kukalwa njengephesenti lobubanzi begobolondo, isb, amaphesenti angama-25 wokusika i-baffle. Usayizi we-baffle-cut (noma iwindi le-baffle) udinga ukucatshangelwa kanye ne-baffle pitch. Kujwayelekile usayizi we-baffle-cut kanye ne-baffle pitch ukuze ulinganise isivinini ngefasitela kanye nokugeleza, ngokulandelana.

Idizayini yemishini yegobolondo nesishintshi sokushisa seshubhu inikeza ulwazi ezintweni ezifana nokujiya kwegobolondo, ukujiya kwe-flange, njll. Lezi zibalwa kusetshenziswa ikhodi yokuklama umkhumbi ocindezelayo njengekhodi ye-Boiler kanye ne-Pressure Vessel evela ku-ASME (American Society of Mechanical Engineers) kanye ne-British Master Pressure Vessel Standard, BS 5500. I-ASME iyikhodi evame ukusetshenziswa kakhulu yezishintshisi zokushisa futhi isezigabeni ezingu-11. Isigaba VIII (Imikhumbi Yokucindezela Okuvinjiwe) yekhodi yisona esisebenza kakhulu ekushintshaniseni ukushisa kodwa iSigaba II—Izinto Ezisetshenziswayo kanye Nesigaba V—Ukuhlola Okungabhubhisi nazo zibalulekile.

Kokubili i-ASME ne-BS5500 zisetshenziswa kabanzi futhi zamukelwa emhlabeni wonke kodwa amanye amazwe agcizelela ukuthi amakhodi awo kazwelonke asetshenziswa. Ukuze uzame ukwenza lokhu kube lula i-International Standards Organisation manje izama ukwakha ikhodi entsha eyaziwa emhlabeni wonke kodwa kungenzeka kube isikhathi ngaphambi kokuba lokhu kwamukelwe.