Ukuhlolwa Kokufakwa Kwepayipi Nokuhlola

Ngesikhathi sokukhiqiza Ukuhlolwa nokuhlolwa okuhlukahlukene kwenziwa ekufakweni kwamapayipi ukuqinisekisa ikhwalithi yomkhiqizo.

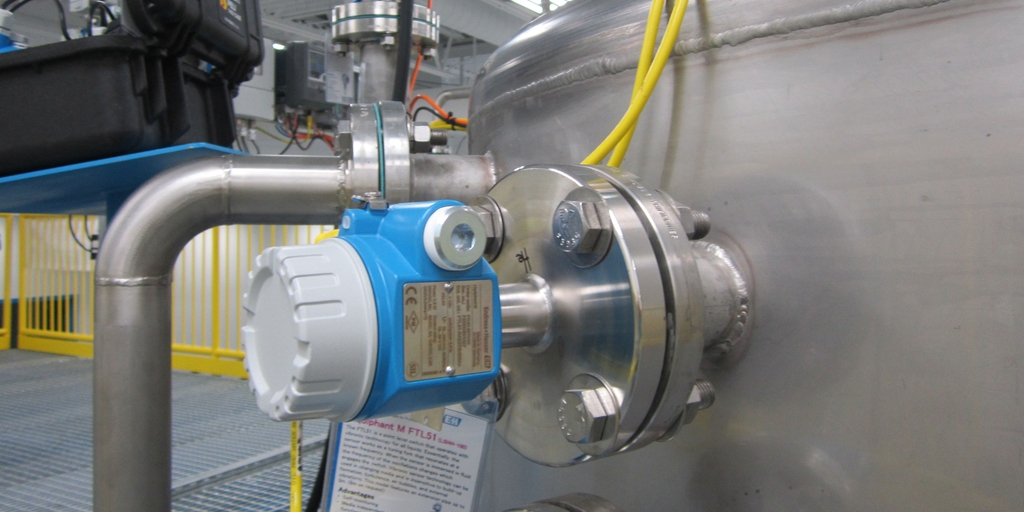

IHydrotest yeUkufakwa Kwepayipi

- Ukuhlolwa kwe-Hydrostatic Akudingeki ekufakweni kwamapayipi ngaphandle uma kucelwe ngokuqondile umthengi

- Ikhodi igunya lokuthi okokufaka kuzokwazi ukumelana ngaphansi kwengcindezi edingwa yi-Piping Code esebenzayo.

- Abathengi abaningi bayagunyaza, ukuthi kusetshenziswe igobolondo lepayipi elihlolwe i-hydro ukuze kwenziwe izinto ezifakwayo.

Ukuhlola Ubufakazi

Ukuhlolwa Kobufakazi beBrust

Ukuze ufaneleke umklamo wokufakwa kwamapayipi, umkhiqizi wenze ukuhlolwa okuhlukahlukene okuhlanganisa nokuqhuma kokuqhuma ukuze kuqinisekiswe ukuthi umklamo uzohlangabezana nazo zonke izidingo ezijwayelekile nekhodi. Kulokhu kuhlolwa, ipayipi nokufakwa kuyashiselwa futhi kulungiswa i-spool yepayipi le-dummy. Le spool yepayipi bese icindezelwa ukuze ichaze kusengaphambili ingcindezi yokuhlolwa kokuqhuma okubaliwe. Uma okokufakwa kumelana nokuhlolwa, wonke umkhiqizo wesikhathi esizayo okhiqizwe kusetshenziswa lowo mklamo uzobhekwa njengophephile ukuthi ungawusebenzisa.

Iziphetho ze-Lap joint stub zikhishiwe ekuhlolweni kobufakazi ngenxa yokuthi zisetshenziswa ngokuhlanganisa i-flange nomklamo kucatshangelwa izilinganiso ezisebenzayo zengcindezi- izinga lokushisa.

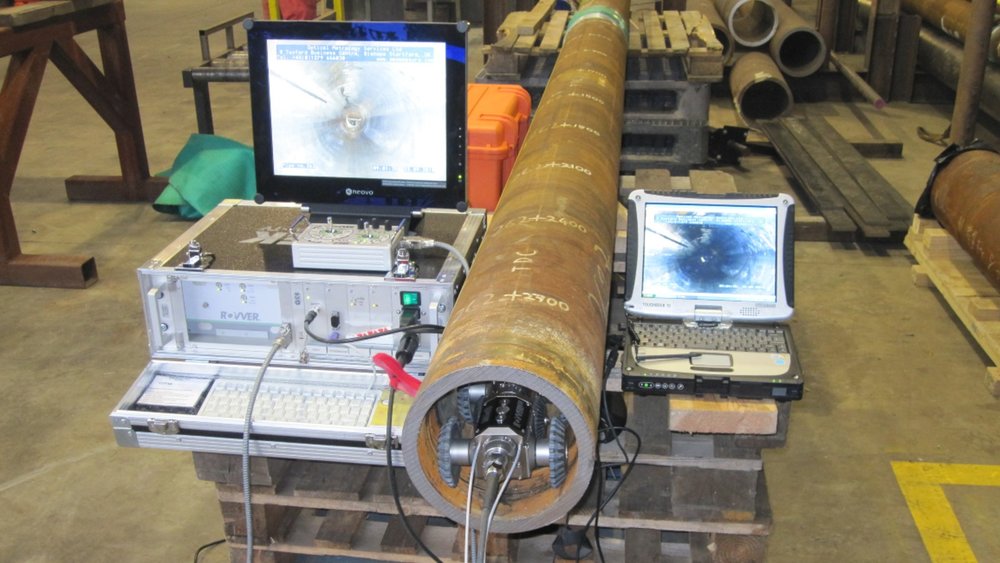

Ukuhlola okungabhubhisi

Ngokusekelwe ohlotsheni lokufakwa noma yikuphi ukuhlolwa okulandelayo Okungonakalisi kwenziwa ekufakweni okuqediwe ukuze kuqinisekiswe ukuzwakala komkhiqizo.

- I-ultrasonic

- I-Radiography (ye-Weld kuphela)

- Ukuhlolwa kwezinhlayiyana kazibuthe

- Ukuhlolwa kokungena koketshezi

- Kanye Nokuhlonza Okubalulekile

Ukuhlola Okulimazayo

Ukuhlolwa Okulimazayo kwenziwa ukuhlola amandla omzimba kanye nokushisela komkhiqizo.

- Ukuhlolwa kobufakazi kwaziwa nangokuthi uhlobo lokuhlola noma ukuhlolwa kokuqhuma.

- Ukuhlolwa kwe-tensile

- Ukuhlolwa komthelela / Ukuhlolwa kwe-Charpy V-Notch

- Ukuhlolwa kokuqina

Ukuhlola Okulimazayo

Ukuhlolwa kweMetallurgical

Ukuhlolwa kwe-Metallurgical kwenziwa emzimbeni wokufakwa kanye nokushiselwa ukuze kuqinisekiswe izidingo ezijwayelekile

- Ukuhlaziya Okuncane noma Ukuhlaziywa Kwekhemikhali kwe

- Impahla eluhlaza

- Umkhiqizo

- Weld

- Ukuhlaziywa kweMacro

- Weld

Ukuhlolwa kweMetallurgical

Ukuhlolwa Okukhethekile

- Ukuhlolwa okukhethekile kuyenziwa ekufakweni ukuze kuqinisekiswe amandla ayo okumelana nezindawo ezonakalisayo. Lezi zivivinyo

- I-IGC- Intergranular Corrosion Test(SS)

- I-Ferrite (SS)

- I-HIC- I-Hydrogen-induced Cracking

- Futhi SSC- Sulfidi Stress Corrosion Cracking

- Usayizi wokusanhlamvu (AS & SS) wezinto ezibonakalayo uyahlolwa ukuze kuqinisekiswe i-microstructure

Ukuhlolwa Okukhethekile

UKUHLOLA OKUBONAKALAYO

Ukuhlola Okubonakalayo kwenziwa ekufakweni ukuze kuhlolwe noma yikuphi ukungapheleli kwendawo. Kokubili umzimba wokufakwa kanye nokushisela kuhlolelwa noma yikuphi ukungapheleli okubonakalayo okufana namazinyo, ama-die marks, i-porosity, ama-undercuts njll. Ukwamukelwa ngokwezinga elisebenzayo.

Ukuhlola Okubonakalayo

Ukumaka Kokufakwa Kwepayipi

Okulandelayo kuzomakwa ku-Fittings

- Ilogo yomkhiqizi

- Ikhodi yezinto ze-ASTM

- Ibanga lezinto ezibonakalayo

- Usayizi, wosayizi we-tee wegatsha & nepayipi eligijima kanye nosayizi oncishisiwe wazo zombili iziphetho

- Ubukhulu (Sheduli Cha) kuzo zombili iziphetho uma zixhunywe kumapayipi okujiya ahlukene

- Ukushisa No

- Ukuthobelana - kokufakwa okujwayelekile -WP, kokufakwa okukhethekile S58, S8, SPLD njll.

Ukumakwa kokufakwa kwamapayipi

Isikhathi sokuthumela: Jun-14-2022