Bagian standar titanium

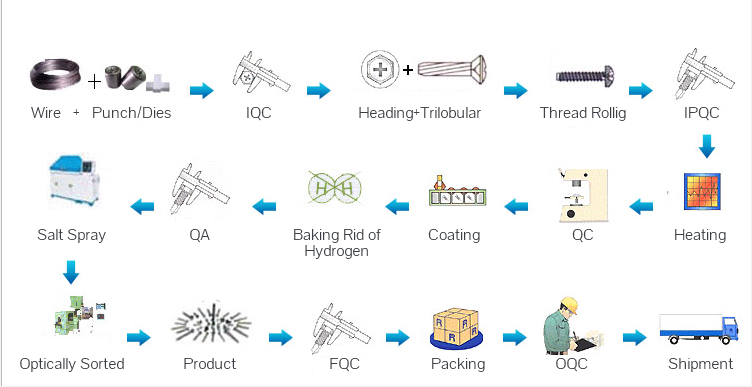

Produksi DIN, ANSI / AMSE, ISO, JIS jeung standar sejen tur non-standar-kakuatan tinggi titanium fasteners.Biasana kalebet baut, sekrup, mur, cuci, cingcin penahan, sareng rupa-rupa potongan khusus.Anu mimiti, urang bakal ngalakukeun perlakuan panas, uji komposisi kimia, uji sipat mékanis tina bar titanium, pelat titanium sareng bahan dasar anu sanés.Saatos prosés straightening, leveling sareng polishing, potong ukuran anu pas.Lajeng lumangsungna péngkolan, stamping panas, screw komprési, perlakuan panas, polishing, beberesih, inspeksi, sarta runtuyan prosedur, antukna ngahasilkeun fasteners titanium kualitas luhur.Kami ngagaduhan alat produksi canggih anu ngajamin produk kami pikeun ngahontal anu pangsaéna dina unggal tautan produksi.

Perusahaan kami ngagaduhan seueur inventaris titanium fasteners, anu tiasa nyugemakeun jumlah pesenan global sareng para nasabah anu peryogi pangiriman anu mendesak.Dina waktu nu sarua, urang ogé nyadiakeun produk non-standar nurutkeun gambar disadiakeun ku konsumén.

Aplikasi

Minyak bumi, metalurgi, kimia, éléktronik, farmasi, rékayasa Kelautan, suku cadang mobil, suku cadang motor, bagian sapédah, asesoris parahu keur pelesir, suplai survival outdoor, barang olahraga sarta widang lianna.

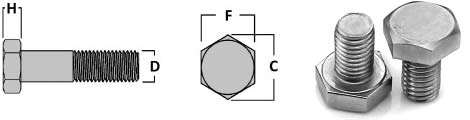

Baud titanium

| produk | Titanium jeung alloy titanium baud |

| Ukuran | Diaméterna: M1.6-M30, Panjangna: 10mm-300mm (0.39″-11.8″) |

| Bahan | Gr.1, Gr.2, Gr.5, Gr.7 jsb |

| Standar | DIN912, DIN6912, DIN933, DIN931 jsb |

Kacang hex titanium

| produk | Titanium jeung Titanium alloy nut |

| Ukuran | M8-M 80 x 6 |

| Bahan | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, jsb |

| Standar | DIN, ISO, JIS, jsb. |

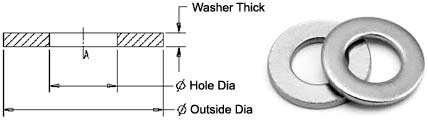

Titanium washer

| produk | Titanium jeung alloy titanium washer |

| Ukuran | OD: 5mm-200mm (0.20″-7.87″), ID: 1mm-100mm (0.04″-3.94″), Kandel: 0.1mm-30mm (0.004″-1.18″) |

| Bahan | Gr.2, Gr.5 jsb |

| Standar | DIN125 jsb |

screw titanium

| produk | Titanium jeung titanium alloy screw |

| Ukuran | M1 nepi ka M42, Panjangna: 10mm-300mm (0.39″-11.8″) |

| Bahan | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 jsb |

| Standar | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, jsb. |

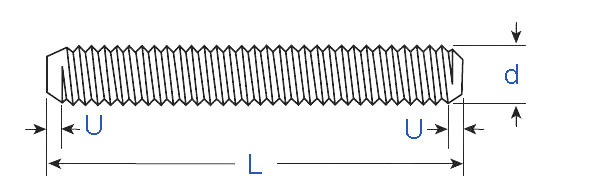

Titanium threaded stud

| produk | Titanium jeung alloy titanium threaded stud |

| Ukuran | Diaméterna: M1.6-M30, Panjangna: 10mm-300mm (0.39″-11.8″) |

| Bahan | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 jsb |

| Standar | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS jsb. |

Titanium Hex Bolts Dimensi

| Hex Hex Bolt Diaméterna | D | F | C | H | |||||

| Diaméter awak | Lebar Sakuliah Datar | Lebar peuntas juru | Jangkungna | ||||||

| Max | Dasar | Max | Min | Max | Min | Dasar | Max | Min | |

| 1/2 | 0,515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 11/32 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0,591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0,876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Ukuran Kacang Hex

| ISO Titanium Hex Nut NB | Di sakuliah Corners | Ketebalan MAX | Ketebalan MIN | MAX Sakuliah Datar | MIN Sakuliah Datar |

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x 6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Titanium Datar Washer Dimensi

| Ti Alloy Bolt Ukuran | USS | SAE | ||||

| OD (dina) | ID (in.) | Kandelna | OD (dina) | ID (in.) | Kandelna | |

| 1/8 (#6) | - | - | - | 0.375 | 0.156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0.438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0,560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0,562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0.875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

| 3/8 | 1.000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0,562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0.938 | .136/.192 | 1.750 | 0.938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249/.327 | - | - | - |

Socket Kepala Cap Screw Dimensi

| Ti Alloy Screw Nom.Ukuran Thread pitch | Awak | Sirah | Sirah | Chamfer | Sagi genep | Spline | konci | Transisi | |||

| Max | Min | Max | Min | Max | Min | Max | Nom. | Nom. | Min | Max | |

| M1,6 × 0,35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0.80 | 2.0 |

| M2 × 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2,5 × 0,45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0,5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1.50 | 3.6 |

| M4 × 0,7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 × 0,8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0.50 | 4.0 | 4.648 | 2.50 | 5.7 |

| M6 × 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 × 1,25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 × 1,5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1,75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2,5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3,5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | … | 15.00 | 33.4 |

| M36 × 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | … | 18.00 | 39.4 |

| M42 × 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | … | 21.00 | 45.6 |

| M48 × 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | … | 24.00 | |

Titanium threaded stud

| ANSI / ASMEB 18.31.2 Threaded rod-Unit: inci | ||||

| d | pitch | |||

| UNC | UNF | 8 UN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0.3125 | 18 | 24 | / |

| 3/8 | 0.375 | 18 | 24 | / |

| 7/16 | 0.4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0,5625 | 12 | 18 | / |

| 5/8 | 0.625 | 11 | 18 | / |

| 3/4 | 0.75 | 10 | 16 | / |

| 7/8 | 0.875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Unit: inci | ||||

| d | pitch | |||

| UNC | UNF | 8 UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2<L≤2-1/2 | 2-1/2<L≤4 | 4<L≤8 | 8<L≤16 | 16<L |

| Fastened kasabaran panjangna stud | ± 0,04 | ± 0,08 | ± 0,10 | ± 0,12 | ± 0,18 |

| Standar | Katerangan | Standar | Katerangan |

| DIN 84 | screws sirah kéju Slotted | DIN 439 | Kacang macét |

| DIN 125 | Washers datar | DIN 963 | Slotted countersunk screws sirah datar |

| DIN 127 | Spring konci washers | DIN 965 | screws mesin sirah datar Phillips |

| DIN 912 | Hex stop kontak sirah screws | DIN 985 | Kacang konci (kalayan sisipan non-logam) |

| DIN913 / DIN 914 / DIN915 / DIN916 | Nyetél screws | DIN 1665/DIN 6921 | Hex bolts kalawan flange |

| DIN 931 | Sekrup tutup sirah hex (bagian benang) | DIN 6912/DIN 7984 | Sagi genep stop kontak screws cap sirah ipis |

| DIN 933 | Sekrup tutup sirah hex (benang pinuh) | DIN 7991 | Sirah datar countersunk stop kontak screws |

| DIN 934 | Kacang hex | DIN 9021 | Washer datar |

Bahan Sarimbag Kelas Pikeun Titanium Fasteners

| STANDAR | WERKSTOFF NR. | UNS |

| Titanium Kelas 2 | 3.7035 | R50400 |

| Titanium Kelas 5 | 3.7165 | R56400 |

Ciri mékanis tina titanium Fasteners

| Kelas | Kakuatan Tensile (mnt) | Kakuatan ngahasilkeun 0,2% Offset | Elongation dina 2 inci atawa 50mm% (min) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20 – 45 | 138 – 310 | 24 |

| Gr.2 | 50 | 345 | 40 – 65 | 275 – 450 | 20 |

| Gr.3 | 65 | 450 | 55 – 80 | 380 – 550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| unsur | Kapadetan | Titik lebur | Kakuatan regangan | Kakuatan ngahasilkeun (0.2% Offset) | Elongation |

| Titanium Gr.2 | 4,5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900, MPa – 344 | Psi – 39900, MPa – 275 | 20% |

| Titanium Gr.5 | 4,43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000, MPa – 950 | Psi – 128000, MPa – 880 | 14% |

Komposisi Bahan Kimia Of Titanium Fasteners

| Kelas | Fe% | C% | N% | H% | O% | Al% | V% | Mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0,015 | 0.18 | — | — | — | — | — | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0,015 | 0.25 | — | — | — | — | — | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0,015 | 0.35 | — | — | — | — | — | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0,015 | 0.40 | — | — | — | — | — | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0,015 | 0.02 | 5.5 – 6.75 | 3.5 – 4.5 | — | — | — | BAL |

| Gr7 | 0.3 | 0.08 | 0.03 | 0,015 | 0.25 | — | — | — | — | 0.12 – 0.25 | BAL. |

| Gr9 | 0.25 | 0.08 | 0.03 | 0,015 | 0.15 | 2.5 – 3.3 | 2.0 – 3.0 | — | — | — | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0,015 | 0.25 | — | — | 0.2 – 0.4 | 0.6 – 0.9 | — | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0,015 | 0.13 | 5.5 – 6.75 | — | — | — | — | B |