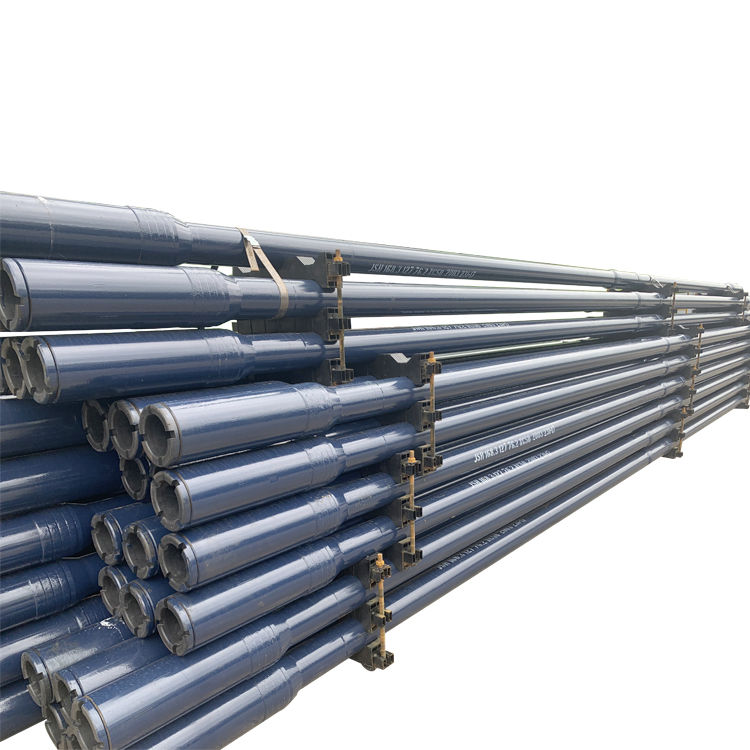

Pipa bor beurat beurat

Pipa bor beurat beurat integral nyaéta zona transisi antara kerah bor sareng pipa bor.Éta henteu ngan ukur tiasa ngirangan formasi setrés dina sambungan kerah bor sareng pipa bor, tapi ogé ngirangan ngagem dina OD.

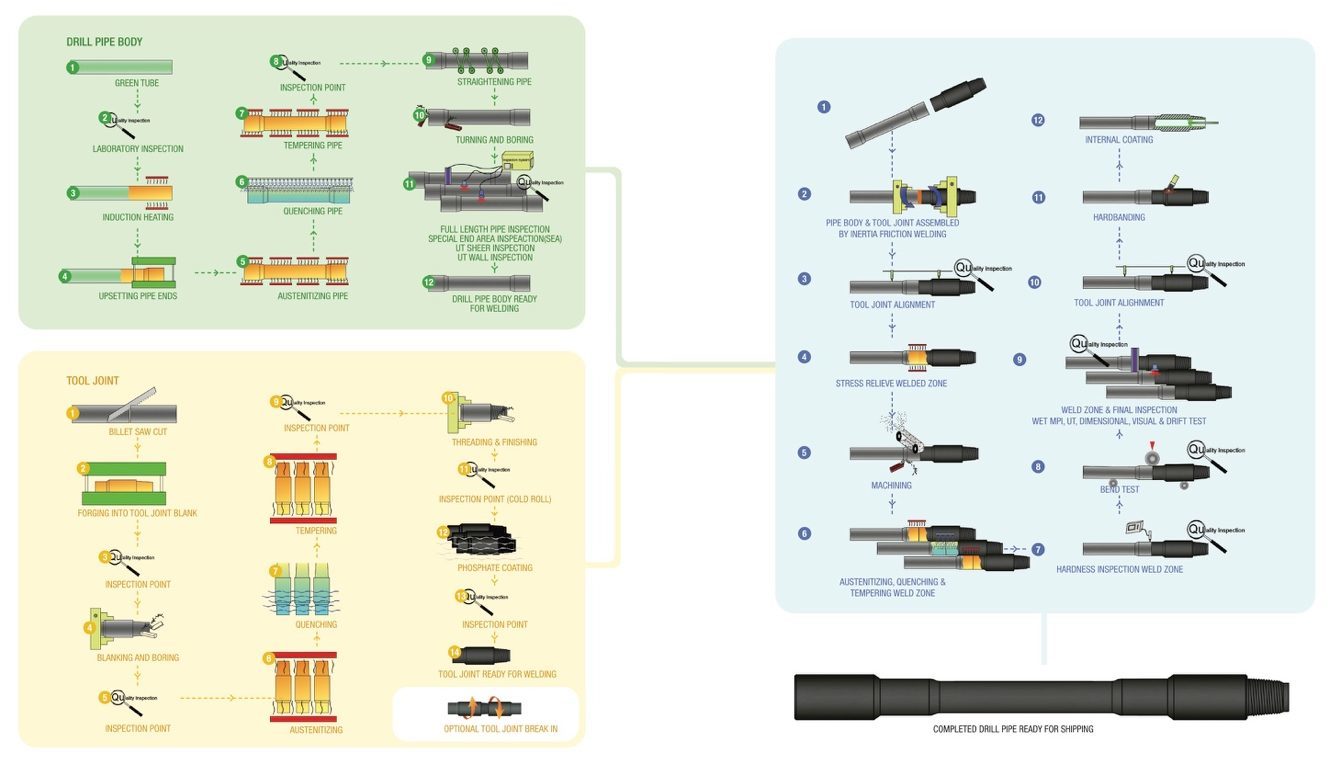

Pipa bor beurat beurat integral dijieun tina hiji sapotong AISI 4145H bar padet, pinuh panas diperlakukeun, sadaya sipat fisik akur jeung API spec7 édisi panganyarna.

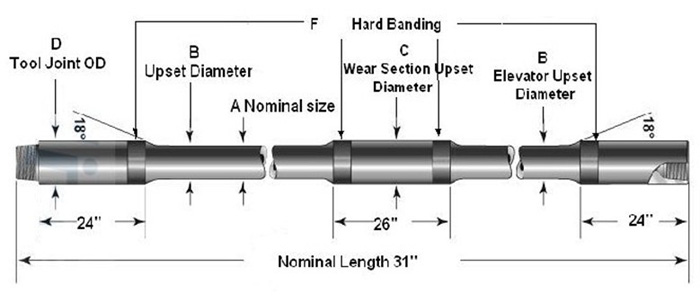

Banding keras tahan tahan HWDP mangrupikeun standar dina sambungan sambungan alat sareng kesel sentral.Jinis hard banding kalebet Arnco 100XT sareng 100XT.Kabéh threads anu phosphated, copperized atawa tiis digawé.Sadaya sambungan dilengkepan pelindung benang baja anu dipencet.Sadaya iklan didamel nganggo mesin bubut CNC - benang ganda sareng benang khusus.

spésifikasi teknis na parameter

| Ukuran (in) | OD (dina) | ID (dina) | Alat Joint OD (in) | ID Gabungan Alat (dina) | Sambungan | Max.elevator diaméterna (in) | Kesel sentral dia.(di) | Min.drift dia.size(in) |

| 3 1/2 | 3 1/2 | 2 1/4 | 4 3/4 | 2 1/4 | NC38 | 3 7/8 | 4 | 2 |

| 2 1/16 | 2 1/16 | 1 13/16 | ||||||

| 4 | 4 | 2 1/2 | 5 1/4 | 2 1/2 | NC40 | 4 3/16 | 4 1/2 | 2 1/4 |

| 2 9/16 | 2 9/16 | 2 5/16 | ||||||

| 4 1/2 | 4 1/2 | 2 11/16 | 6 1/4 | 2 11/16 | NC46 | 4 11/16 | 5 | 2 7/16 |

| 2 3/4 | 2 3/4 | 2 1/2 | ||||||

| 2 13/16 | 2 13/16 | 2 9/16 | ||||||

| 5 | 5 | 3 | 6 5/8 | 3 | NC50 | 5 1/8 | 5 1/2 | 2 3/4 |

| 5 1/2 | 5 1/2 | 3 1/4 | 7 | 3 1/4 | 5 1/2 FH | 5 11/16 | 6 | 3 |

| 3 3/8 | 3 3/8 | 3 1/8 | ||||||

| 3 7/8 | 3 7/8 | 3 5/8 | ||||||

| 4 | 4 | 3 3/4 | ||||||

| 6 5/8 | 6 5/8 | 4 | 8 | 4 | 6 5/8 FH | 6 15/16 | 7 1/8 | 3 3/4 |

| 4 1/2 | 4 1/2 | 4 1/4 | ||||||

| 5 | 5 | 4 3/4 |

| Pipa bor beurat spiral | ||||||||

| Spésifikasi mm | tabung | Bareng | ||||||

| ID mm | Lift keselmm | alur lift / Slip luar diametermm | Screw diaméterna mm | Jero alur spiral mm | Tipe Thread | OD mm | ID mm | |

| 88.9(3 1/2) | 54 | 92.1 | 88.9 | 101.6 | 9.5 | NC38 | 120.6 | 54 |

| 114.3(4 1/2) | 69.8 | 117.5 | 114.3 | 127 | 12.7 | NC46 | 158.8 | 69.8 |

| 127.0(5) | 76.2 | 130.2 | 127 | 139.7 | 12.7 | NC50 | 165.1 | 76.2 |

| Steel Tandaan | Komposisi Kimia% | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Al | |

| 4145H | 0.42~0.48 | 0.15~0.35 | 0.90~1.20 | ≤0.03 | ≤0.03 | 0.90~1.20 | 0.15~0.25 | ≤0.2 | 0,025~0.045 |

| Unsur séjén:N≤0,015,Ni≤0.5 | |||||||||

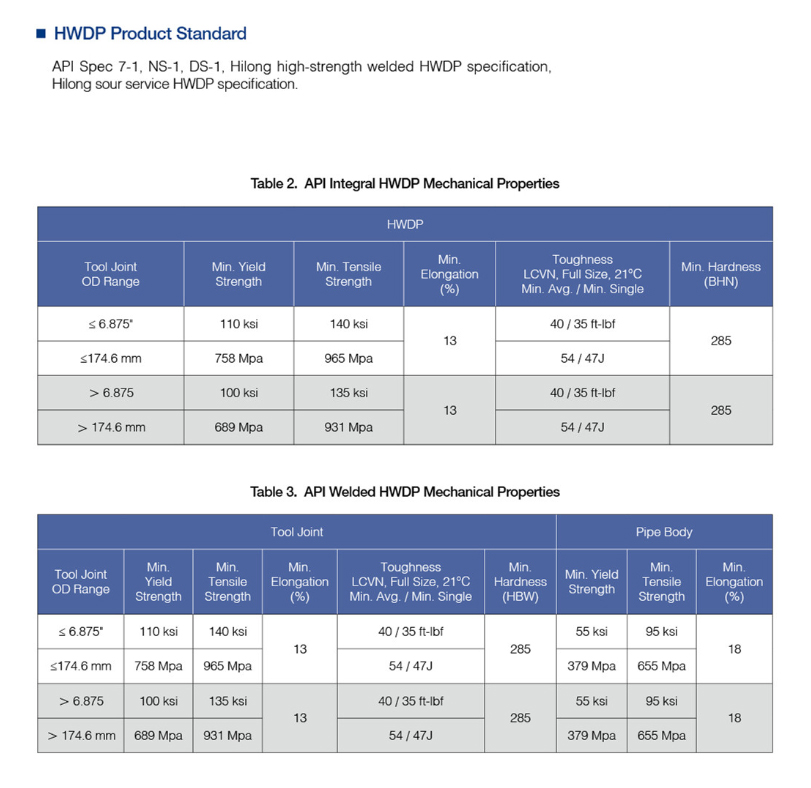

| Aplikasi | Bahan | Ukuran | Kakuatan ngahasilkeun (Min KSI) | Kakuatan pamungkas (Min KSI) | Teuas Brinell (HB) | Elongation (A%) | Charpy Min (ft-lbs @+20°C) |

| Standar integral | AISI 4145H dirobah | Sadayana | 110 | 140 | 285 nepi ka 340 | 13 | 40 |

| Dilas Standar | AISI 1340 dirobah | Sadayana | 65 | 95 | 235 (maks) | 18 | 30 |

| Dilas NS-1 | AISI 4140H dirobah | Sadayana | 120 | 140 | 285 nepi ka 340 | 13 | 40 |

| Dilas Standar | AISI 4140H dirobah | Di luhur 7 1/4" | 120 | 140 | 285 nepi ka 340 | 13 | 40 |

| Standar dilas | AISI 4140H dirobah | Nepi ka 7 1/4" | 100 | 135 | 285 nepi ka 340 | 13 | 40 |

| HWDP-110 HW MS | ASCOWELL C | Di luhur 6 3/4" | 110 | 140 | 285 nepi ka 340 | 13 | 0 |

| HWDP-110 HW MS | ASCOWELL C | Nepi ka 6 3/4" | 100 | 135 | 285 nepi ka 340 | 13 | 55 |

| HWDP-65 HW MS (alat gabungan) | ASCOWELL C | Di luhur 6 3/4" | 110 | 140 | 285 nepi ka 340 | 13 | 55 |

| HWDP-65 HW MS (alat gabungan) | ASCOWELL C | Nepi ka 6 3/4" | 100 | 135 | 285 nepi ka 340 | 13 | 55 |

| HWDP-65 HW MS | AISI 1340 dirobah | Sadayana | 65 | 95 | 235 (maks) | 18 | 30 |