plat baja stainless

310/310S lambaran stainless steel

310 stainless steel austenitic kromium nikel stainless steel boga résistansi oksidasi alus, résistansi korosi, sabab persentase luhur kromium jeung nikel, 310 boga kakuatan ngabdi leuwih hadé, terus bisa dianggo dina suhu luhur, résistansi panas alus.

310S stainless steel nyaeta austenitic kromium nikel stainless steel, ngabogaan alus 310S résistansi oksidasi stainless steel, lalawanan Corrosive.

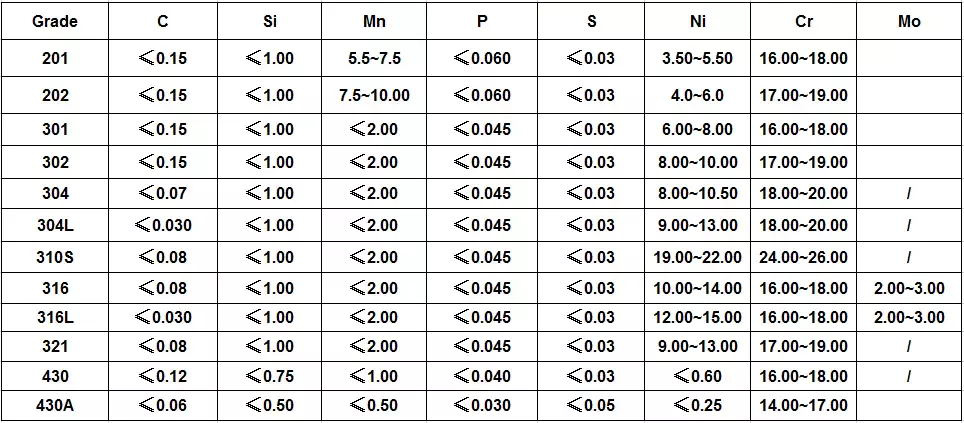

Bedana komposisi kimia pikeun 310/310S stainelss steel

| Kelas | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | N(%) | Cu(%) |

| 310 | ≤0.25 | ≤1.0 | ≤2.0 | ≤0.03 | --- | 24.0-26.0 | 19.0-22.0 | --- | --- |

| 310S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.03 | ≤0.03 | 24.0-26.0 | 19.0-22.0 | --- | --- |

Bedana sipat Mechanical pikeun 310/310S stainless steel

| Kelas | kakuatan reganganMpa | Kakuatan ngahasilkeunMpa | Elongation(%) | laju ngurangan di wewengkon(%) | Kapadetan(g/cm3) |

| 310 | ≥470 | ≥17 | ≥40 | ≥50 | 7.98 |

| 310S | ≥520 | ≥205 | ≥40 | ≥50 | 7.98 |

304/304L/304H lambar stainless

Ngeunaan 304 bahan:304 stainless steel mangrupakeun bahan stainless steel umum, dénsitas 7,93 g / cm3, industri disebut oge 18/8 stainless steel.résistansi suhu luhur 800 derajat, kalawan kinerja processing alus, ciri kateguhan tinggi, loba dipaké dina industri hiasan industri jeung jati jeung industri pangan.

Ngeunaan 304L bahan:304L baja salaku low C dina kaayaan umum, lalawanan korosi sarta 304 sarupa, tapi sanggeus las atawa stress sanggeus lalawanan korosi na alus teuing pikeun wates sisikian.Dina kasus tanpa perlakuan panas, bisa tetep lalawanan korosi alus, umumna make 400 atawa kirang (non-magnét, hawa -196 darajat Celsius nepi ka 800 darajat Celsius).Loba dipaké pikeun ngahasilkeun syarat kinerja sakabéh alus (tahan korosi jeung formability) pakakas jeung bagian.

Ngeunaan 304H bahan:304H mangrupakeun jenis stainless steel, kalawan bending alus, kinerja prosés las, résistansi korosi, durability tinggi jeung stabilitas organisasi, kamampuhan deformasi tiis pohara alus.Suhu pangluhurna tiasa ngahontal 650 DEG C, sareng résistansi oksidasi dugi ka 850 DEG C

Bedana komposisi Kimia pikeun 304 304L 304H

| Kelas | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | N(%) | |

| 304 | ≤0.08 | ≤0.75 | ≤2.0 | ≤0,045 | ≤0.03 | 18.0-20.0 | 8.0-10.5 | ≤0.1 | |

| 304L | ≤0.03 | ≤0.75 | ≤2.0 | ≤0,045 | ≤0.03 | 18.0-20.0 | 8.0-12.0 | ≤0.1 | |

| 304H | 0.04-1.0 | ≤0.75 | ≤2.0 | ≤0,045 | ≤0.03 | 18.0-20.0 | 8.0-10.5 | ---- | |

Bedana sipat Mechanical pikeun 304 304L 304H

| Kelas | kakuatan regangan(Mpa) | Kakuatan ngahasilkeun(Mpa) | Elongation(%) | Teu karasa(HR) |

| 304 | ≥515 | ≥205 | ≥40 | ≥92 |

| 304L | ≥485 | ≥170 | ≥40 | ≥92 |

| 304H | ≥515 | ≥205 | ≥40 | ≥92 |

316/316L lambaran stainless steel

Ngeunaan 316 bahan:316 stainless steel ku nambahkeun unsur Mo, résistansi korosi, sarta kakuatan suhu luhur geus greatly ningkat, suhu luhur bisa ngahontal 1200-1300 derajat, bisa dipaké dina conditions.Corrosion parna résistansi leuwih hade tinimbang 304 stainless steel, dina produksi pulp jeung kertas. prosés ngabogaan lalawanan korosi alus.Jeung 316 stainless steel oge tahan ka erosi atmosfir industri laut jeung corrosive.

Ngeunaan 316L bahan:316L stainless steel boga eusi karbon kirang ti 316, nu ilahar dipaké dina bubur jeung kertas alat exchangers panas, alat dyeing, parabot cuci pilem, pipelines, wewengkon basisir luar bahan wangunan.lalawanan korosi leuwih hade tinimbang 316 bahan.

Bedana komposisi kimia pikeun 316 316L stainless steel

| Kelas | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | Cu(%) |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0,045 | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0,045 | ≤0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

Bedana sipat Mechanical pikeun 316 316L stainless steel

| Kelas | kakuatan reganganMpa | Kakuatan ngahasilkeunMpa | Elongation(%) | laju ngurangan di wewengkon(%) | Kapadetan(g/cm3) |

| 316 | ≥520 | ≥205 | ≥40 | ≥60 | 7.98 |

| 316L | ≥480 | ≥177 | ≥40 | ≥60 | 7.98 |

430 lambaran stainless steel

430 stainless steel mangrupakeun résistansi korosi hade baja umum, kinerja termal ti alus austenitic, koefisien ékspansi termal ti austenitic leutik, kacapean panas, tambahkeun unsur stabilisasi titanium, bagian weld kinerja mékanis anu alus.

430 stainless steel dipaké dina pamakéan arsitéktur, bagian burner suluh, panerapan rumah tangga, bagian parabot imah.

Komposisi kimia pikeun 430 stainelss steel

| Kelas | C(%) | Mn(%) | Si(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | Cu(%) |

| 430 | ≤0.12 | ≤1.0 | ≤0.75 | ≤0.04 | ≤0.03 | 16.0-18.0 | ≤0.06 | --- | --- |

sipat mékanis pikeun 430 stainless steel

| Kelas | kakuatan reganganMpa | Kakuatan ngahasilkeunMpa | Elongation(%) | laju ngurangan di wewengkon(%) | Kapadetan(g/cm3) |

| 430 | ≥450 | ≥205 | ≥22 | --- | 7.75 |

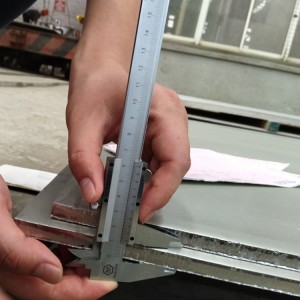

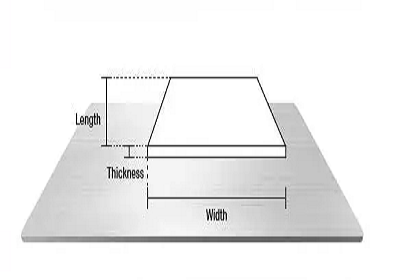

| Kelas | Bérés | Ketebalan (mm) | Lebar (mm) | Panjangna (mm) |

| 310 | 2B / No.4 / HL / BA / Eunteung jsb | 0.4mm-0.3mm | Lebar baku di Cina: 1000mm 1219mm 1500mm | |

| 310s | No.1 | 3.0mm-80.0mm | Lebar baku di Cina: 1219mm 1500mm 2000mm | |

| 304 | 2B, No.4 PE | 0.55 | 914, 1219 | 1828, 2438 |

| 304 | 2B, No 4 PE | 0.70 | 914, 1219 | 1828, 2438 |

| 304 | 2B, 2B PE, No 4 PE, BA PE | 0.90 | 914, 1219 | 1828, 2438 |

| 304 | 2B, 2B PE, No 4 PE, BA PE | 1.20 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No 4 PE | 1.50 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No 4 PE | 1.60 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No 4 PE | 2.00 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No 4 PE | 2.50 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304 | 2B, 2B PE, No 4 PE | 3.00 | 914, 1219, 1500 | 1828, 2438, 3000, 3048, 3658 |

| 304L | 2B, 2B PE | 4.00 | 1500, 2000 | 3000, 6000 |

| 304H | 2B / No.4 / HL / BA / Eunteung jsbNo.1 | 3.00 | 1219, 1500,2000 | |

| 310 | 2B / No.4 / HL / BA / | 0.4-0.3 | 1000.1219.1500 | |

| 310s | No.1 | 3.00 | 1219, 1500,2000 | |

| 316 | 2B | 0.55 | 1219 | 2438 |

| 316 | 2B | 0.70 | 1219 | 2438 |

| 316 | 2B | 0.90 | 1219 | 2438 |

| 316 | 2B, No.4 PE | 1.20 | 1219 | 2438 |

| 316 | 2B, No.4 PE | 1.50 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B, No.4 PE | 1.60 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B, No.4 PE | 2.00 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B, No.4 PE | 2.50 | 1219, 1500 | 2438, 3000, 3658 |

| 316 | 2B, No.4 PE | 3.00 | 1219, 1500 | 2438, 3000, 3658 |

| 316L | 2B, 2B PE | 4.00 | 1500, 2000 | 3000, 6000 |

| 430 | BA PE, No 4 PE | 0.70 | 914, 1219 | 1828, 2438 |

| 430 | BA PE, No 4 PE | 0.90 | 914, 1219 | 1828, 2438 |

| 3CR12 | 2B | 1.2 | 1250 | 2500 |

| 3CR12 | 2B | 1.6 | 1250 | 2500 |

| 3CR12 | 2B | 2.0 | 1250 | 2500 |

| 3CR12 | No. 1 | 4.0 | 1250, 1500 | 2500, 3000, 6000 |

sasmita sejen tur lega

Sasmita: 301L, 310, 321, 2205, 253MA.

Lebar (mm): 600, 750, 900, 1050, 1200, 1524.

310/310S lambaran stainless steel

| Kelas | GB / T 1220-2007 | ASTM | DIN | JIS | KS |

| 310 | 20Cr25Ni20 | 310 | 1.4821 | SUS310 | STS310 |

| 310S | 06Cr25Ni20 | 310S | 1.4845 | SUS310S | STS310S |

Standar pikeun 304 304L 304H stainless steel

| Kelas | GB / T 1220-2007 | ASTM | DIN | JIS | KS |

| 304 | 06Cr19Ni10 | 304 | 1.4301 | SUS304 | STS304 |

| 304L | 022Cr19Ni10 | 304L | 1.4306 | SUS304L | STS304L |

| 304H | —- | 304H | —- | SUS304H | STS304H |

Standar pikeun 316/316L stainless steel

| Kelas | GB / T 1220-2007 | ASTM | DIN | JIS | KS |

| 316 | 06Cr17Ni12Mo2 | 316 | 1.4401 | SUS316 | STS316 |

| 316L | 022Cr17Ni12Mo | 316L | 1.4404 | SUS316L | STS316L |

Standar pikeun430beusi sténless

| Kelas | GB | ASTM | DIN | JIS |

| 316 | 10Cr17 | 430 | 1.4016 | SUS430 |

| Kandelna | Massa nominal Austenitic (kg/m²) | Beurat nominal feritik (kg/m²) |

| 0.45 | 3.68 | |

| 0.55 | 4.50 | |

| 0.70 | 5.72 | |

| 0.90 | 7.36 | |

| 1.20 | 9.81 | 9.61 |

| 1.50 | 12.3 | |

| 1.60 | 13.08 | 12.85 |

| 2.00 | 16.35 | 16.02 |

| 2.50 | 20.44 | 20.03 |

| 3.00 | 24.53 | 24.04 |

| 4.00 | 32.71 | 32.06 |

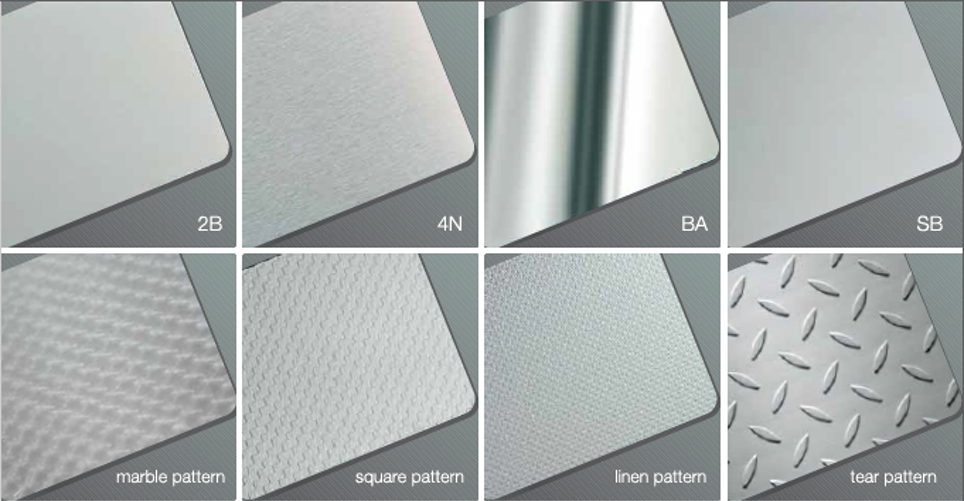

| Surface Finish | Harti | Aplikasi |

| 2B | Anu rengse, sanggeus rolling tiis, ku perlakuan panas, pickling atawa perlakuan sarimbag sejen tur panungtungan ku rolling tiis mun dibere luster luyu. | Alat médis, industri pangan, bahan konstruksi, parabot dapur. |

| BA | Maranéhanana diolah kalayan perlakuan panas caang sanggeus rolling tiis. | Parabot Dapur, Peralatan Listrik, Pangwangunan Gedong. |

| NO.3 | Maranéhanana réngsé ku polishing kalawan No.100 mun No.120 abrasives dieusian dina JIS R6001. | parabot dapur, wangunan wangunan. |

| NO.4 | Maranéhanana réngsé ku polishing kalawan No.150 mun No.180 abrasives dieusian dina JIS R6001. | Parabot dapur, Konstruksi Gedong, Parabot Médis. |

| HL | Anu réngsé polishing ku kituna méré corétan polishing kontinyu ku cara maké abrasive ukuran sisikian cocog. | Pangwangunan Gedong. |

| NO.1 | Beungeut réngsé ku perlakuan panas sarta pickling atawa prosés pakait aya sanggeus rolling panas. | Tangki kimia, pipa. |

| No.8 | Réngsé 'eunteung' anu réfléktif.Dihasilkeun tina 2B finish ku polishing jeung abrasives finer saterusna dituturkeun ku buffing éksténsif.Utamana dipaké dina aplikasi arsitéktur. | |

| Palanggan-spésifik | Réngsé 'eunteung' anu réfléktif.Dihasilkeun tina 2B finish ku polishing jeung abrasives finer saterusna dituturkeun ku buffing éksténsif.Utamana dipaké dina aplikasi arsitéktur. |