Pipa alloy nikel

| Bahan | Monel / Inconel / Hastelloy / Duplex Steel / PH Steel / Nikel alloy |

| Wangun | Buleud, Forging, Ring, Coil, Flange, Disc, Foil, Bulat, Pita, Kotak, Bar, Pipa, Lembar |

| Kelas | N02200, N02201, N04400, N06600, N06601, N06625, N06690, N08810, N08825, N08020, N11,0280 665,N06022,N06030,GH3030,GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel690 NS1NS311431 NS112, Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4 Monel K500, N05500 |

| Spésifikasi | Lain: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 jsb |

| alloy:alloy 625,Paduan 20/28/31 | |

| Hastelloy: Hastelloy B / -2 / B-3 / C22 / C-4 / S / C276 / C-2000 / G-35 / G-30 / X / N / g; | |

| Hastelloy B / UNS N10001, Hastelloy B-2 / UNS N10665 / DIN W. Nr.2.4617, Hastelloy C, Hastelloy C-4 / UNS N06455 / DIN W. Nr.2.4610, Hastelloy C-22 / UNS N06022 / DIN W. Nr.2.4602, Hastelloy C-276 / UNS N10276 / DIN W. Nr.2.4819, Hastelloy X / UNS N06002 / DIN W. Nr.2.4665 | |

| Haynes: Haynes 230/556/188; | |

| runtuyan Inconel:Inconel 600/601/602CA/617/625/690/713/718/738/X-750, Tukang Kayu 20; | |

| Inconel 718 / UNS N07718 /N04400/N06600/N08825/DIN W. Nr.2.4668, Inconel 601 / UNS N06601 / DIN W. Nr.2.4851, Inconel 625 / UNS N06625 / DIN W. Nr.2.4856, Inconel 725 / UNS N07725, Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669, Inconel 600 / UNS N06600 / DIN W. Nr.2.4816 | |

| Incoloy:Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel:Monel 400 / K500/R405 | |

| Nitronik: Nitronik 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Kawat: 0.01-10mm Jalur: 0,05 * 5,0-5,0 * 250mm Bar: φ4-50mm; Panjangna 2000-5000mm Pipa: φ6-273mm;δ1-30mm;Panjang 1000-8000mm Lambaran: δ 0.8-36mm; Lebar 650-2000mm; Panjangna 800-4500mm | |

| produk Ciri | 1. Nurutkeun kana prosés préparasi bisa dibagi kana superalloys deformasi, casting superalloys jeung bubuk metallurgy superalloys. 2. Nurutkeun kana modeu strengthening, aya solusi solid strengthening tipe, présipitasi tipe strengthening, dispersi oksida tipe strengthening sarta serat strengthening tipe, jsb. |

| Standar | GB,AISI,ASTM,DIN,EN,SUS,UNS jsb |

| Pamariksaan | ISO, SGS, BV, jeung saterusna. |

| Aplikasi | Komponén suhu luhur sapertos bilah turbin, baling-baling pituduh, piringan turbin, tekanan tinggi compressor disk, manufaktur mesin jeung kamar durukan dipaké dina pabrik aviation, angkatan laut jeung turbin gas industri |

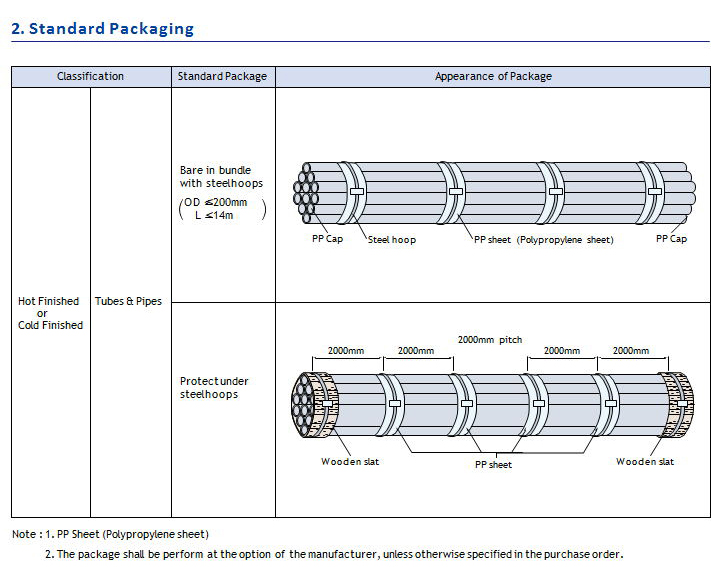

| Bungkusan | 1. kasus dipak dina kasus kai 2. bungkusan kertas 3. packing palastik 4. bungkusan busa Bungkusan nurutkeun sarat customer atawa produk |

| Pangiriman | 7-25days atanapi nurutkeun produk |

| pangmayaran | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Nurutkeun pamayaran sarat customer pikeun pesenan offline. |

| UKURAN STOK | |||||||||||||

| UKURAN | nikel | PADUNGAN | PADUNGAN | PADUNGAN | PADUNGAN | PADUNGAN | PADUNGAN | PADUNGAN | PADUNGAN | PADUNGAN | PADUNGAN | UKURAN | |

| 1/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 1,65 mm | |

| 0.010 | X | X | .25 mm | ||||||||||

| 0.020 | X | .51 mm | |||||||||||

| 1/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 3,18 mm | |

| 0.010 | X | 0.25 | |||||||||||

| 0.012 | X | 3,05 mm | |||||||||||

| 0.016 | X | .31 mm | |||||||||||

| 0.020 | X | X | X | .51 mm | |||||||||

| 0,028 | X | X | X | X | .71 mm | ||||||||

| 0.035 | X | X | X | X | .89 mm | ||||||||

| 3/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 4,76 mm | |

| 0.010 | X | .25 mm | |||||||||||

| 0.016 | X | X | .31 mm | ||||||||||

| 0.020 | X | .51 mm | |||||||||||

| 0,028 | X | X | X | .71 mm | |||||||||

| 0.035 | X | X | X | X | X | X | .89 mm | ||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 6,35 mm | |

| 0.016 | X | .31 mm | |||||||||||

| 0.020 | X | X | X | .51 mm | |||||||||

| 0,028 | X | X | X | X | X | .71 mm | |||||||

| 0.035 | X | X | X | X | X | X | X | X | .89 mm | ||||

| 0.049 | X | X | X | X | X | X | X | X | 1,24 mm | ||||

| 0,065 | X | X | X | X | X | X | X | 1,65 mm | |||||

| 0.083 | X | 2,11 mm | |||||||||||

| 5/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 7,94 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0.035 | X | X | X | .89 mm | |||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 3/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 9,53 mm | |

| 0.020 | X | .51 mm | |||||||||||

| 0,028 | X | X | X | X | .71 mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | .89 mm | ||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | 1,65 mm | |||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 7/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 11,1 mm | |

| 0.035 | X | .89 mm | |||||||||||

| 0,065 | X | 1,65 mm | |||||||||||

| 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 12,7 mm | |

| 0,028 | X | X | X | X | .71 mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | X | .89 mm | |||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,058 | X | X | 1,47 mm | ||||||||||

| 0,065 | X | X | X | X | X | X | X | X | 1,65 mm | ||||

| 0.083 | X | X | X | 2,11 mm | |||||||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | 2,77 mm | |||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 9/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 14,3 mm | |

| 0.035 | X | X | X | .89 mm | |||||||||

| 0.049 | X | X | X | X | 1,24 mm | ||||||||

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 0.083 | X | 2,11 mm | |||||||||||

| 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 15,9 mm | |

| 0.035 | X | X | X | X | X | .89 mm | |||||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 3/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 19,1 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0.035 | X | X | X | X | X | X | X | .89 mm | |||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | X | X | X | 1,65 mm | ||

| 0.083 | X | X | X | X | X | X | X | 2,11 mm | |||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | X | X | X | 2,77 mm | ||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 22,2 mm | |

| 0.035 | X | X | X | .89 mm | |||||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 1″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 25,4 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0.035 | X | X | X | X | X | X | .89 mm | ||||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | X | 1,65 mm | ||||

| 0.083 | X | X | X | X | X | X | X | 2,11 mm | |||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | X | X | X | 2,77 mm | ||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.134 | X | X | |||||||||||

| 1 1/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 28,6 mm | |

| 0.049 | X | ||||||||||||

| 1 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 31,8 mm | |

| 0.035 | X | X | X | .89 mm | |||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0.083 | X | X | X | X | 2,11 mm | ||||||||

| 0.095 | X | 2,41 mm | |||||||||||

| 0.109 | X | 2,77 mm | |||||||||||

| 0.120 | X | X | 3,05 mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 38,1 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0.035 | X | X | .89 mm | ||||||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0.083 | X | X | X | 2,11 mm | |||||||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | X | X | 2,77 mm | |||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 41,3 mm | |

| 0,065 | X | 1,65 mm | |||||||||||

| 0.083 | X | 2,11 mm | |||||||||||

| 1 3/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 44,5 mm | |

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 1 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 47,6 mm | |

| 0.083 | X | 2,11 mm | |||||||||||

| 2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 50,8 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0.035 | X | X | .89 mm | ||||||||||

| 0.049 | X | X | 1,24 mm | ||||||||||

| 0,065 | X | X | X | X | X | 1,65 mm | |||||||

| 0.083 | X | X | X | X | 2,11 mm | ||||||||

| 0.095 | X | 2,41 mm | |||||||||||

| 0.109 | X | X | 2,77 mm | ||||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 2 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 57,2 mm | |

| 0.035 | X | .89 mm | |||||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 2 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 63,5 mm | |

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 0.109 | X | 2,77 mm | |||||||||||

| 0.120 | X | X | 3,05 mm | ||||||||||

| 3″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 76,2 mm | |

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0.083 | X | X | X | 2,11 mm | |||||||||

| 0.120 | X | X | 3,05 mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.250 | X | 6.35 | |||||||||||

| 3 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 82,6 mm | |

| 0.125 | X | 3.18 | |||||||||||

| 3 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 88,9 mm | |

| 0.375 | 9,53 mm | ||||||||||||

| Standar | - ASTM A270, ASTM A249, ASTM A511, ASTM A778, ASTM A312, ASTM A358, ASTM A409, ASTM A213, ASTM A790, ASTM A268, ASTM A269, ASTM A554, ASTM B333, ASTM B338, ASTM767 B675, ASTM B676, ASTM B690, ASTM A928, ASME B36.19, ASME B36.10– EN10216-5, EN10217-7, DIN 17456, DIN 17458 – JIS G3463,JIS G3119,JIS G3446,JIS G3218,JIS G3258,JIS G3448,JIS H4631– DEP 31,DEP 40,DEP 20,DEP 32,DNV-OS-F101 |

| Rentang Ukuran | OD:NPS 1/8 -80, BN 6 – 2000, 10.3 – 2030, kapiler AlaoWT:Sch5s-Sch160s, SchXXH, STD, XS, XXSPanjangna:Kustomisasi |

| Kelas | S32750. 4948, 06Cr23Ni13, S30908, SUS309S, SUS310S, 1.4845, S31008, S31008S, 06Cr25Ni20, 0Cr25Ni20, 1.4401 / 1.4404 / 316/31, S31635, SUS316Ti, 1.4571, 1.4571 / 316Ti, S31703, 022Cr19Ni13Mo3, 00Cr17Ni12Mo2, S31314, S31303, SUS. 410S, 1.4, 06Cr13, S11306, 0Cr13, S42000, SUS420J1, 1.4021, SUS420J2, 1.4028, S43020, 430F, SUS430F, 1.4104, , 301, 302, 303, 305, 309, 310, 316, 317, 321, 347, 403, 41, 42,45 07, 304/304L, 304DQ . 0, 630, XM19, C4, S30815 , S31254, 174PH, F51, F60, F53, S32760, 253MA, HC2000, 800H, 926, GH2132, GH4169, GH3030, GH3039, GH4151, N0434, N0430, N0430 08810 |

| ASTM B111 / ASME SB111 | Spésifikasi Standar pikeun Tambaga sareng Tambaga-Alloy Seamless Condenser Tubes sareng Ferrule Stock | |

| ASTM B161 / ASME SB161 | Spésifikasi Standar pikeun Nikel Seamless Pipa jeung Tube | |

| ASTM B163 / ASME SB163 | Spésifikasi Standar pikeun Seamless Nikel sareng Nikel Alloy Condenser sareng Tabung Penukar Panas | |

| ASTM B165 / ASME SB165 | Spésifikasi Standar pikeun Nikel-Tambaga Alloy (UNS N04400)* Pipa Seamless sareng Tube | |

| ASTM B167 / ASME SB167 | Spésifikasi Standar pikeun Nikel-Kromium-Beusi Alloy, Nikel-Kromium-Kobalt-Molybdenum Alloy (UNS N06617), sarta Nikel-Beusi-Chromium-Tungsten Alloy (UNS N06674) Seamless Pipa jeung Tube | |

| ASTM B395 / ASME SB395 | Spésifikasi Standar pikeun U-Bend Seamless Tambaga sareng Tambaga Alloy Heat Exchanger sareng Condenser Tubes | |

| ASTM B407 | Spésifikasi Standar pikeun Nikel-Beusi-Kromium Alloy Seamless Pipa sarta Tube | |

| ASTM B423 / ASME SB423 | Spésifikasi Standar pikeun Nikel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 sareng UNS N06852) sareng Nikel-Chromium-Molybdenum-Silicon Alloys (UNS N06219) Pipa sareng Tube | |

| ASTM B444 / ASME SB444 | Spésifikasi Standar pikeun Nikel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 sareng UNS N06852) sareng Nikel-Chromium-Molybdenum-Silicon Alloys (UNS N06219) Pipa sareng Tube | |

| ASTM B622 / ASME SB622 | Spésifikasi Standar pikeun Seamless Nikel sareng Nikel-Kobalt Alloy Pipa sareng Tube | |

| ASTM B668 / ASME SB668 | Spésifikasi Standar pikeun UNS N08028 sareng N08029 Pipa Seamless sareng Tube | |

| ASTM B677 / ASME SB677 | Spésifikasi Standar pikeun UNS N08925, UNS N08354, sareng UNS N08926 Pipa Seamless sareng Tube | |

| ASME SB690 / ASME SB690 | Spésifikasi Standar pikeun Paduan Beusi-Nikel-Kromium-Molybdenum (UNS N08366 sareng UNS N08367) Pipa sareng Tube Seamless | |

| ASTM B705 / ASME SB705 | Spésifikasi Standar pikeun Nikel-Alloy (UNS N06625, N06219 sareng N08825) Dilas Pipa | |

| ASTM B729 / ASME SB729 | Spésifikasi Standar pikeun mulus UNS N08020, UNS N08026, sareng UNS N08024 pipa alloy nikel sareng Tube | |

| ASTM B829 / ASME SB829 | Spésifikasi Standar pikeun Sarat Umum pikeun Nikel sareng Nikel Paduan Seamless Pipa sareng Tube |

Komposisi kimia:

| Kelas | Komposisi kimiawi | ||||||||

| C | Ieu max | Mn max | P | S | Ni | Cr | Mo | Ti | |

| 200 | 0.15 | 0.35 | 0.35 | 0.010 | 99 mnt | ||||

| 201 | 0.02 | 0.35 | 0.35 | 0.010 | 99 mnt | ||||

| 400 | 0.30 | 0.50 | 2.00 | 0,024 | 63 mnt | ||||

| 600 | 0.15 | 0.50 | 1.00 | 0,015 | 72 mnt | 14 – 17 | |||

| 601 | 0.10 | 0.50 | 1.00 | 0,015 | 58 – 63 | 21 – 25 | |||

| 625 | 0.10 | 0.50 | 0.50 | 0,015 | 0,015 | 58 mnt | 20 – 23 | 8 – 10 | 0,40 max |

| 800 | 0.10 | 1.00 | 1.50 | 0.03 | 0,015 | 30 – 35 | 19 – 23 | 0.15 0.60 | |

| 800H | 0.05 0.10 | 1.00 | 1.50 | 0,015 | 30 – 35 | 19 – 23 | 0.15 0.60 | ||

| 825 | 0.05 | 0.50 | 1.00 | 0.03 | 38 – 46 | 19.5 23.5 | 2.5 3.5 | 0.6 1.2 | |

| 904L | 0.02 | 1.00 | 2.00 | 0.030 | 0,015 | 24 – 26 | 19 23 | 4 5 | |

Nikel Alloy Pasipatan fisik

| PADUNGAN | Kapadetan alloy nikel | TERMAL, KONDUKTIVITAS | LINEAR TERMAL , KOEFF ékspansi., (20-95 °C) | RESISTITIVITAS ELEKTRIK, PADA 20°C |

| G/CM³ | W/MK | 10-6/K | ΜΩ-CM | |

| NI 200/201 | 8.89 | 70.20 | 13.3 | 9 |

| NI 205/205 LC | 8.89 | 75.00 | 13.3 | 8.9 |