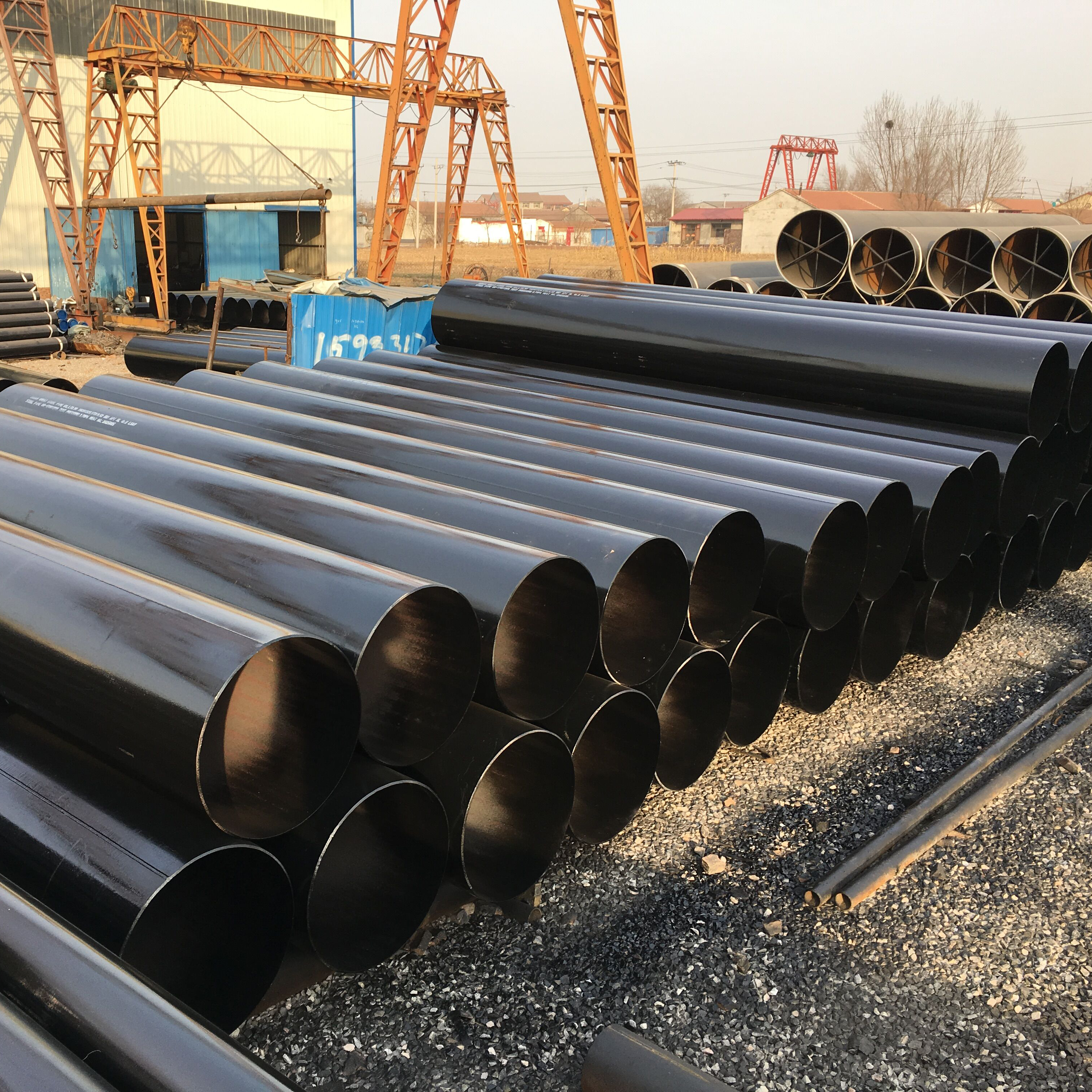

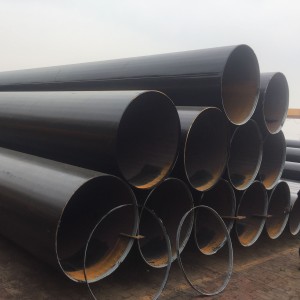

Pipa Baja LSAW

LSAW Steel Pipe ( Longitudinal Seam Submerged Arc Welding Pipe )

Pipa baja UOE LSAW

Pabrik UOE gaduh téknologi sareng prosés anu paling canggih, ngahontal efisiensi produksi anu luhur, kualitas produk anu stabil sareng dilengkepan alat pamariksaan lengkep.UOE ngagiling adopts U & O ngabentuk, pipa kabentuk anu dilas jero ngaliwatan lima stasiun las internal kalayan tilu kawat, sarta dilas luar ngaliwatan opat stasiun las éksternal kalawan tilu kawat.Luyu jeung sarat béda konsumén, pipa dilas bisa dimekarkeun boh ku mékanis atawa hydrostatic dilegakeun pikeun ngaronjatkeun akurasi dimensi, sarta ngaleungitkeun stress residual.

spésifikasi

Diaméter luar 508mm- 1118mm (20"- 44")

Ketebalan témbok: 6.0-25.4mm 1/4 "-1"

Standar Kualitas: API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Panjangna: 9-12.3m (30'- 40')

Kelas: API 5L A-X90,GB/T9711 L190-L625

Pipa LSAW JOCE

Ieu diaméterna badag longitudinal submerged arc dilas (LSAW) garis produksi pipe di Cina.Ngagiling nu adopts prosés bending kutang, featuring merata ngabentuk stress, uniformity tinggi tina dimensi, variasi ukuran taya & rentang prouct lega, sarta kalenturan tinggi, jsb.

spésifikasi

Diaméter luar: Φ406mm- 1626mm (16" - 64")

Ketebalan Tembok:6.0-75mm (1/4" - 3")

Standar kualitas:API、DNV、ISO、DEP、EN、ASTM、DIN、BS、JIS、GB、CSA

Panjangna:3-12.5m ( 10'- 41' )

Sasmita:API 5L A-X100, GB / T9711 L190-L690

LSAW Steel Pipa Dimensi

| Diaméterna kaluar | Ketebalan témbok (mm) | ||||||||||||||||

| Inci | mm | 6.4 | 7.1 | 7.9 | 9.53 | 12.7 | 14.3 | 15.9 | 19.1 | 22.2 | 25.4 | 28.6 | 31.8 | 34.9 | 38.1 | 41.3 | 44.5 |

| 16 | 406.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 22 | 559 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 24 | 610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 26 | 660 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 28 | 711 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 30 | 762 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 32 | 813 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 34 | 864 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 36 | 914 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 38 | 965 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 40 | 1016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 42 | 1067 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 44 | 1118 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 46 | 1168 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 48 | 1219 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 52 | 1321 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 56 | 1422 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 60 | 1524 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 64 | 1626 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Toleransi Diaméter Luar sareng Ketebalan Tembok

| Jenis | Standar | |||||

| SY / T5040-2000 | SY / T5037-2000 | SY / T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

| Tabung tungtung OD simpangan | ± 0,5% D | ± 0,5% D | -0,79 mm~+2,38 mm | <± 0,1% T | <± 0,1% T | ± 1,6 mm |

| Kandel témbok | ± 10,0% T | D <508mm, ± 12,5% T | -8%T~+ 19,5% T | <-12,5% T | -8%T~+ 19,5% T | 5,0 mm |

| D> 508mm, ± 10,0% T | T≥15.0mm, ±1.5mm | |||||

Komposisi Kimia sareng Sipat Mékanis

| Standar | Kelas | Komposisi Kimia (max)% | Sipat mékanis (min) | |||||

| C | Mn | Si | S | P | Kakuatan ngahasilkeun (Mpa) | Kakuatan Tensile (Mpa) | ||

| GB / T700-2006 | A | 0.22 | 1.4 | 0.35 | 0,050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0,040 | 0,040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB / T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS En10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0,050 | 0,050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0,050 | 0,050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0,040 | 0,040 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0,050 | 0,050 | 235 | 400 |

| SS490 | - | - | - | 0,050 | 0,050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Diminyakan ringan, Hot dip galvanis, Electro galvanized, Hideung, Bare, Lapisan Varnish/Minyak Anti karat, Lapisan Pelindung