Paduan Seamless Pipa

OD: 6-720MM

WT: 0.5-120MM

Panjangna: 3-16M

Aplikasi: Minyak bumi, Téknik Kimia, Listrik, Boiler

Standar: ASTM A335 / A335M, ASTM A213 / 213M, DIN17175-79, JIS3467-88, GB5310-95

Bahan: P5, T5, P11, P12, STFA22, P22, T91, T9, WB36

Pipa alloy mangrupikeun jinis pipa baja seamless, kinerjana langkung luhur tibatan pipa baja seamless umum, sabab pipa baja jinis ieu ngandung langkung Cr, résistansi suhu luhur, résistansi suhu rendah, kinerja résistansi korosi langkung saé tibatan anu sanés. Pipa baja, jadi pipa alloy loba dipaké dina minyak bumi, aerospace, kimia, kakuatan listrik, alat keur ngagolakkeun, militer jeung industri lianna.

| produk | SEAMLESS / ERW / SAW ALLOY pipa baja |

| Diménsi | 6 mm - 1080 mm |

| Kandelna | 1mm - 135 mm |

| Panjangna | 3 m - 12 m atawa nurutkeun sarat tina klien |

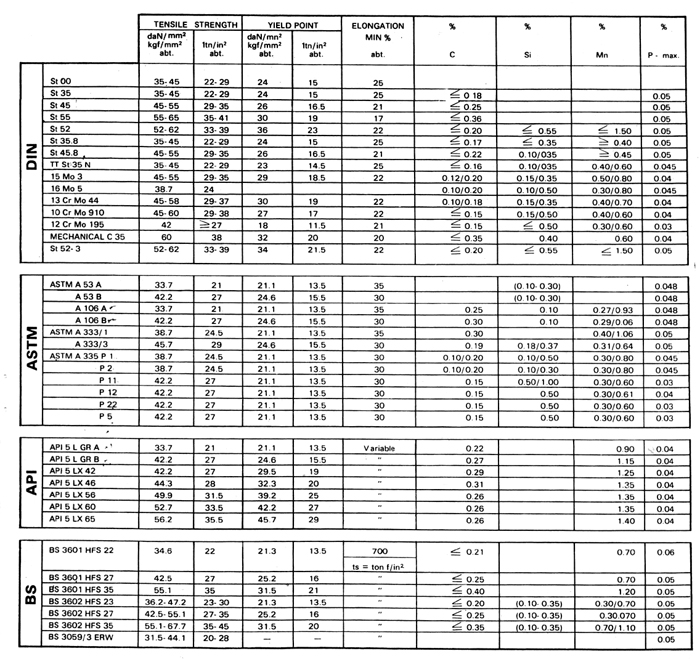

| Standar | ASTM GB DIN |

| Kelas baja | A106/53/179/214/192/210 A/B/CST37.2/35.4/35.8/52/52.3/52.4/42/4510# 20# 45#P2, P12, P11, P22, P5, P29, P91T , T11, T5, T9, T22, 4140, 12CrMo, 15CrMo, 12Cr2Mo, 1Cr5Mo, 2CrMo4, 1Cr9Mo, 10CrMo910, jsb. |

| Sarat dagang | FOB / CIF / CFR |

| istilah pamayaran | T/T, L/C |

| palabuhan pangiriman | Tianjin, Cina |

| Waktos pangiriman | 10 atawa nurutkeun kuantitas nyata tina tabung |

| Perlakuan permukaan | Hideung paintingVarnish painting3PEHot galvanizedor palapis séjén nurutkeun sarat Anjeun Bare tube |

| Tungtung tabung | Beveled, polos, benang, cap plastik |

| Pamariksaan | Pamariksaan ultrasonik, pamariksaan eddy, uji hidrostika jsb. |

| Bungkusan | Bundles, loosen atawa nurutkeun sarat Anjeun |

| Sertipikat | API 5L/5CT, ISO, PED jsb. |

Komposisi kimiawi

| C,% | Mn,% | P,% | S, % | Si, % | Kr,% | Mo,% |

| 0.05-0.15 | 0.30-0.60 | 0,025 max | 0,025 max | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

Sipat mékanis

| Kakuatan Tensile, MPa | Kakuatan ngahasilkeun, MPa | Elongasi,% |

| 415 mnt | 205 mnt | 30 mnt |

Diaméter luar & Toleransi

| ASTM A450 | Panas digulung | Diaméter luar, mm | Toleransi, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| Digambar Tiis | Diaméter luar, mm | Toleransi, mm | |

| OD<25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1<OD<50.8 | ±0.20 | ||

| 50.8≤OD<63.5 | ±0.25 | ||

| 63.5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190.5 | +0.38/-0.64 | ||

| 190.5<OD≤228.6 | +0.38/-1.14 | ||

| ASTM A530 & ASTM A335 | NPS | Diaméter luar, inci | Toleransi, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1,59/-0,79 | ||

| 8<OD≤12 | +2,38/-0,79 | ||

| OD> 12 | ±1% |

Ketebalan témbok & Toleransi

| ASTM A450 | Panas digulung | Diaméter luar, mm | Toleransi,% |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT> 4.6 | +28/-0 | ||

| OD> 101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD> 101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD> 101.6, WT> 4.6 | +28/-0 | ||

| Digambar Tiis | Diaméter luar, mm | Toleransi,% | |

| OD≤38.1 | +20/-0 | ||

| OD> 38.1 | +22/-0 | ||

| ASTM A530 | NPS | Diaméter luar, inci | Toleransi,% |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

ASTM A335-pikeun Seamless Ferritic Alloy-Steel Pipe pikeun Service Suhu Luhur

ASTM A519-pikeun Seamless Carbon sareng Alloy Steel Mechanical Tubing

ASTM A213-pikeun Seamless Ferritic and Austenitic Alloy-Steel Boiler, Super heater, sareng Heat-Exchange Tubes

ASTM ASME (S)A-335/(S)A-335M Kelas jeung Komposisi Kimia

| Kelas | UNS | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0,025 | 0,025 | 0.10~0.50 | - | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0,025 | 0,025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0,025 | 0,025 | 0.50 | 4.00 ~ 6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0,025 | 0,025 | 1.00 ~ 2.00 | 4.00 ~ 6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0,025 | 0,025 | 0.50 | 4.00 ~ 6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0,025 | 0,025 | 0.50~1.00 | 8.00-10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0,025 | 0,025 | 0.50~1.00 | 1.00 ~ 1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0,025 | 0,025 | 0.50 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0,025 | 0,025 | 1.15~1.65 | - | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0,025 | 0,025 | 0.50 | 2.65~3.35 | 0,80 ~ 1,60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0,025 | 0,025 | 0.50 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.020 | 0.010 | 0,20 ~ 0,50 | 8.00 ~ 9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.020 | 0.010 | 0.50 | 8.50~9.50 | 0.30~0.60 |

Catetan: (S)A335 P91 komposisi kimia lianna nyaéta: V 0.18~0.25;N 0,030~0,070;Ni≤0,40;Al≤0,04 ;Nb 0,06~0,10

(S)A335 P92 komposisi kimia lianna nyaéta: V 0.15~0.25;N 0,030~0,070;Ni≤0,40;Al≤0,04 ;Nb 0,04~0,09;W 1.5~2.00 ;B 0,001~0,006

Palapis hideung, minyak / varnish, FBE, 2PE, 3PE, galvanized jsb Bungkusan Rincian: Packing di bundles atawa pikeun sarat klien urang