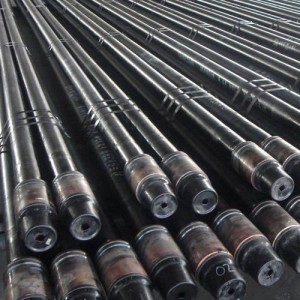

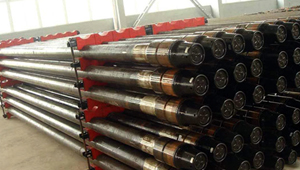

Pipa bor

Pipa bor: Pipa bor ngawengku awak pipa jeung alat sendi (kotak jeung pin) dilas babarengan, dipaké pikeun nyambungkeun pangeboran rig alat permukaan jeung alat handap atawa alat-alat liang handap.Pipa bor tiasa nanggung tekanan internal sareng éksternal anu beurat, sareng pulas, ngabengkokkeun sareng geter anu tiasa dianggo langkung ti hiji waktos salami produksi minyak atanapi gas.

Pipa bor nyaéta tubular baja dipasangan tungtung threaded disebut alat mendi, nu ilahar dipaké dina tegangan dina bagian luhur string bor pikeun ngompa cairan sarta ngirimkeun torsi ka bit.

Standar: Pipa bor

Kelas: E75, X95, G105, S135.

Sabuk anu tahan ngagem tina gabungan alat: Arnco 100XT, 200XT, 300XT, 400XT

Pipa bor palapis internal: TK34, DPC, TC2000, TC3000

Pamakéan: peledakan tambang, pangeboran sumur cai, pangeboran sumur panas bumi, poling payun, proyek pertambangan batubara sareng logam nonferrous, jsb.

ukuran:

| Sebutan ukuran | beurat diitung | Tanda gabungan alat | beurat diitung | kelas | Kandel témbok | Kesel tamat | ||

| in | 1b/ft | Kg/m | in | mm | ||||

| 2 3/8 | 6.65 | NC26 | 6.26 | 9.32 | EXGS | 0.28 | 7.11 | EU |

| 2 7/8 | 10.4 | NC31 | 9.72 | 14.48 | EXGS | 0.362 | 9.19 | EU |

| 3 1/2 | 13.3 | NC38 | 12.31 | 18.34 | EXGS | 0.368 | 9.35 | EU |

| 3 1/2 | 15.5 | NC38, NC40 | 14.63 | 21.79 | EXGS | 0.449 | 11.4 | EU |

| 4 | 14 | NC40, NC46 | 12.93 | 19.26 | EXGS | 0.33 | 8.38 | IU, EU |

| 4 1/2 | 16.6 | NC46, NC50 | 14.98 | 22.31 | EXGS | 0.337 | 8.56 | EU, IEU |

| 4 1/2 | 20 | NC46, NC50 | 18.69 | 27.84 | EXGS | 0.43 | 10.92 | EU, IEU |

| 5 | 19.5 | NC50, NC52 | 17.93 | 26.71 | EXGS | 0.362 | 9.19 | IEU |

| 5 | 25.6 | NC50,5 1/2FH | 24.03 | 35.79 | EXGS | 0.5 | 12.7 | IEU |

| 5 1/2 | 21.9 | 5 1/2FH | 19.81 | 29.51 | EXGS | 0.361 | 9.17 | IEU |

| 5 1/2 | 24.7 | 5 1/2FH | 22.54 | 33.57 | EXGS | 0.415 | 10.54 | IEU |

| 6 5/8 | 25.2 | 6 5/8FH | 22.19 | 33 | EXGS | 0.33 | 8.387 | IEU |

| 6 5/8 | 27.7 | 6 5/8FH | 24.21 | 41 | EXGS | 0.362 | 9.19 | IEU |

Komposisi Kimia (%):

| Kelas | Komposisi kimiawi | |

| P | S | |

| E75 | <0,015 | <0.003 |

| X95 | <0,015 | <0.003 |

| G105 | <0,015 | <0.003 |

| S135 | <0,015 | <0.003 |

| Alat gabungan | <0,015 | <0.003 |

Sipat mékanis:

| Awak pipa | Kelas | kakuatan ngahasilkeun | Kakuatan regangan | Elongation | Teu karasa | Uji dampak charpy ukuran pinuh (J) | ||||||

| min | max | min | min | |||||||||

| Psi | MPa | Psi | MPa | Psi | MPa | HBW | HRC | Rata-rata | Bujang | |||

| E75 | 75000 | 517 | 105000 | 724 | 100000 | 689 | 625000A0.2/U0.9 | - | - | 80 | 65 | |

| X95 | 95000 | 655 | 125000 | 862 | 105000 | 724 | - | - | 80 | 65 | ||

| G105 | 105000 | 724 | 135000 | 931 | 115000 | 793 | - | - | 80 | 65 | ||

| S135 | 135000 | 931 | 165000 | 1138 | 145000 | 1000 | - | - | 80 | 65 | ||

| zona las | Alat gabungan | 120000 | 827.4 | - | - | 140000 | 965.3 | =13% | =285 | - | 80 | 65 |

| E75 | 75000 | 517 | - | - | 100000 | 689 | - | ?37 | 40 | 27 | ||

| X95 | 88000 | 609 | - | - | 103000 | 712 | - | ?37 | 40 | 27 | ||

| G105 | 95000 | 655 | - | - | 105000 | 724 | - | ?37 | 40 | 27 | ||

| S135 | 105000 | 724 | - | - | 115000 | ?37 | 40 | 27 | ||||

cet dumasar cai anti korosi