ERW Steel Pipa

(1) pipa dilas tina las pelat baja kana pipa buleud, dibagi kana pipa las lalawanan frekuensi tinggi (pipa las RW), pipa las busur kelim lempeng (LSAW), pipa las spiral. Téknik listrik sareng "SC", tiasa dianggo sakumaha pipe gas cai ogé bisa dipaké salaku threading pipe, rélatif kandel.

(2) Pipeline pipe, ogé katelah pipe kawat, relatif ipis, dilambangkeun ku "T", sarta ngan bisa dipaké pikeun threading.ERW steel pipeERW steel pipe.

(3) ERW tube nyaeta "frekuensi tinggi lalawanan las tube baja", sarta prosés las umum mah béda, garis weld nyaeta tina bahan dasar awak sabuk baja dilebur, kakuatan mékanis leuwih hade tinimbang welding.ERW umum nangtung. pikeun las lalawanan, las lalawanan boga ciri efisiensi produksi tinggi, béaya rendah, hemat bahan jeung automation gampang, ku kituna loba dipaké dina aviation, aerospace, énergi, éléktronika, otomotif, industri lampu jeung séktor industri lianna, nyaeta salah sahiji prosés las penting.

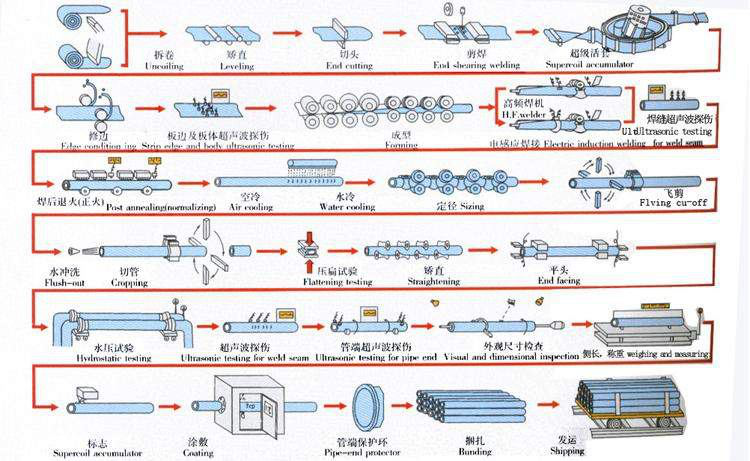

Prosés produksi pikeun pipa baja ERW:

Uncoiling --- 2. Leveling --- 3. Tungtung motong --- 4. Tungtung shearing las --- 5. Supercoil accumulator --- 6. Tepi motong --- 7. Ultrasonic deteksi --- 8. Ngabentuk - -- 9. las induksi listrik --- 10. Deteksi ultrasonik pikeun kelim weld --- 11. perlakuan panas frékuénsi sedeng --- 12. cooling hawa --- 13. cooling cai --- 14. Sizing --- 15 Ngalayang motong --- 16. Flush-out --- 17. Cropping --- 18. Flattening nguji --- 19. Straightening --- 20. tungtung nyanghareup jeung bevelling --- 21. Hydrodynamic testing --- 22 . Deteksi ultrasonik pikeun kelim las --- 23. Deteksi ultrasonik pikeun tungtung pipa --- 24. Inspeksi visual sareng dimensi --- 25. Timbangan sareng pangukuran --- 26. Nyirian --- 27. Palapis --- 28. Perlindungan pipa-tungtung --- 29. Bending --- 30. Pengiriman barang

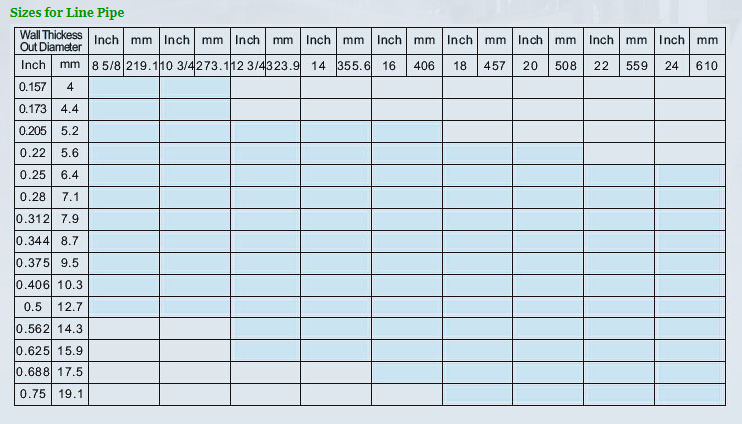

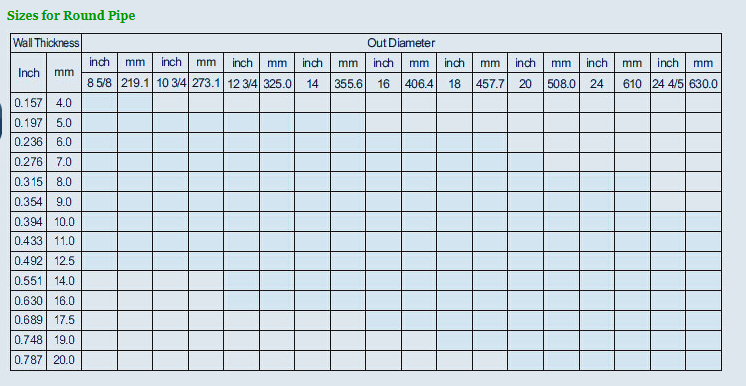

Dimensi, Spésifikasi, Ukuran ERW Steel Pipe

| OD | WT | |||||||||||||||||||||||||

| Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | Inci | mm | |

| 0.157 | 4 | 0.173 | 4.4 | 0.205 | 5.2 | 0.22 | 5.6 | 0.25 | 6.4 | 0.28 | 7.1 | 0.312 | 7.9 | 0.344 | 8.7 | 0.375 | 9.5 | 0.406 | 10.3 | 0.5 | 12.7 | 0,562 | 14.3 | |||

| 8 5/8 | 219.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10 3/4 | 273.1 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 12 3/4 | 323.9 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 14 | 355.6 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 16 | 406 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 10022 | 559 |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||

| 241 | 610 |

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||

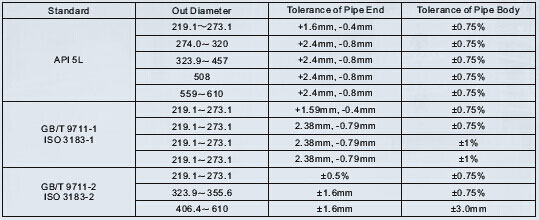

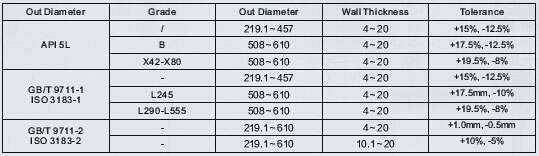

Tolerances of Luar diaméterna - ERW Steel pipe

Toleransi Tembok Kandel - ERW Steel Pipe

Diminyakan ringan, Hot dip galvanis, Electro galvanized, Hideung, Bare, Lapisan Varnish/Minyak Anti karat, Lapisan Pelindung