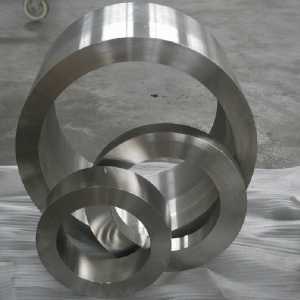

Titanium Cingcin

Cingcin titanium badag dijieun ku mesin ring grinding badag, cingcin titanium leutik bisa dihontal ku mesin forging.Salaku parusahaan jeung leuwih ti 20 taun pangalaman produksi, urang boga runtuyan prosés forging rigorous jeung manual operasi, kaasup léngkah pemanasan, waktos pemanasan sarta waktu pelestarian panas.Mesin tempa gancang 35MN sareng 16MN ngajamin sababaraha tempa dina kisaran suhu anu cocog, sareng ngarobih struktur fisik internal cincin titanium.Greatly ningkat kualitas produk urang.

Salian ring titanium, kami ogé nyadiakeun produksi titanium disc, titanium block jsb.

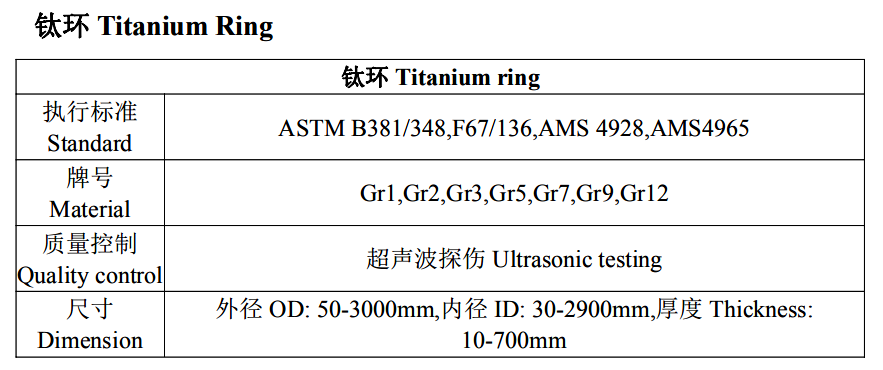

| Ngaran Produk | Titanium Cingcin |

| Ukuran | OD (max 3000mm)×ID (max 2900mm)×panjangna (panjangna maksimum 1000mm) |

| Kelas | TA1/TA2/TA5/TA6/TA9/TA10/TA15/TA19/TC1/TC2/TC4/TC11/ GR1 / GR2 / GR5 / GR7 / GR9 / GR12 / GR23 |

| Standar | ASTM B381/348, F67/136, AMS4928, AMS4965,AMS,MIL,DIN,BS,JIS,GB / T,ISOjsb |

| Kapadetan | 4,51g / cm3 kinerja High forging industri, gr12 Titanium ngajalin ring rolling |

| Téknologi | Forging, rolling, grinding kinerja tinggi industri forging GR12 titanium forging ring rolling |

| Tipe | Prosés rolling cingcin mulus ngalibatkeun motong liang dina bahan ngajalin jeung rolling kana cingcin ipis. Dibandingkeun sareng pelat firing atanapi butt las, cingcin tempa digulung nyadiakeun pamutahiran concentric kalawan ring permukaan lemes. Ring kinerja tinggi industri ngajalin GR12 titanium ngajalin ring rolling |

| Aplikasi | 1. Electroplating;2.Téknologi kimia sareng pétrokimia;3.Médis kinerja tinggi industri forging GR12 titanium forging ring rolling |

ASTM B381/348, F67/136, AMS4928, AMS4965

Komposisi kimiawi

| Kelas | Komposisi kimia, persén beurat (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Unsur séjén Max.masing-masing | Unsur séjén Max.total | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0,015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0,015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0,015 | 0.30 | — | — | 0.12~0.25 | — | 0.12~0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0,015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04~0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.1 |

sipat fisik

| Kelas | sipat fisik | |||||

| Kakuatan regangan Min | kakuatan ngahasilkeun Min (0,2%, offset) | Elongation dina 4D Min (%) | Ngurangan Wewengkon Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |