Titanium Wire / Xariir

Waxaan ku siin karnaa siliga tantalum ee vacuum biam elektarooniga dhalaalidda iyo tignoolajiyada birta budada ah, Ujeedada guud ee siliga tantalum waxaa soo saaray tignoolajiyada dhalaalayasha alwaax elektarooniga ah, waxay leedahay nadiifnimo xad dhaaf ah.Siligga tantalum darajada Capacitor sida caadiga ah waxaa soo saaray tignoolajiyada biraha budada ah, waxay ka kooban tahay walxo bir ah oo gaar ah.Siliga Tantalum waxa la soo saaray iyadoo lagu salaynayo baarka tantalum.marka hore, soo rogista cabbirka ku habboon ee tantalum bar, nadiifinta tantalum bar, si ay meesha uga saarto joornaalka dusha sare iyo wasakhowga saliidda, gooynta bar tantalum iyo nadiifinta mar kale, ka dibna iyada oo la kala bixinayo iyo annealing marar badan, ugu dambeyntii hel qeexitaannada shuruudaha macaamiisha , iyada oo loo marayo nadiifinta, toosinta, dabaysha, waxaan ku heli karnaa siliga tooska ah ama gariiradda.Habka gaarka ah ee birta Giant ee duubista, habka fidinta, xakamaynta saamiga cadaadiska, heerkulka nuugista iyo xakamaynta wakhtiga ayaa dammaanad qaadi kara siliga tantalumku wuxuu leeyahay sifooyin farsamo oo aad u fiican, ka dhigaya dusha mid siman, nadiif ah, saliid la'aan, ma jiro dildilaacyo iyo burs, ma jiraan wax jahwareer ah. oo lagu arkay in ka yar 25 jeer weynaynta, ma laha jeexjeexyo joogto ah iyo xoqan, waxay leeyihiin qaab-dhismeed bir ah oo wanaagsan, si loo hubiyo tayada fiilada tantalum waxay ka fiican tahay shirkadaha kale ee isku midka ah.

Intaa waxaa dheer in ay bixiso silig tantalum saafi ah, shirkadeena waxay sidoo kale bixisaa silig tantalum alloy ah.

Qalab:

Tantalum Niobium silig (TaNb3, TaNb20, TaNb40)

Tantalum Tungsten silig (Ta2.5W, Ta10W)

Dhexroorka: 0.1 ~ 4mm

Heerka: ASTM B365

Qaabka: Toosan, Gariiradda

Xaaladda: Adag, Semi-adag, Dhexdhexaad

Codsiga

Siliga tantalum darajada capacitor waxa inta badan loo isticmaalaa samaynta tantalum electrolytic capacitor anode lead.Siliga tantalum waa sheyga muhiimka ah ee capacitor tantalum, capacitor tantalum waa capacitor-ka ugu fiican, qiyaastii 65% tantalumka aduunka ee loo isticmaalo goobtan.

Loo isticmaalo in lagu soo saaro mesh tantalum.

Loo isticmaalo in lagu tolo si loo magdhabo nudaha muruqa, tolida neerfaha iyo seedaha, soo saarista xididdada dhiigga stent, iwm.

Loo isticmaalo in lagu soo saaro vacuum foornada heerkul sare qaybaha kuleylka.

Waxaa loo isticmaalaa faakuum elektaroonig ah oo soo saaraysa isha cathode, ion sputtering iyo alaabta daahan, iwm.

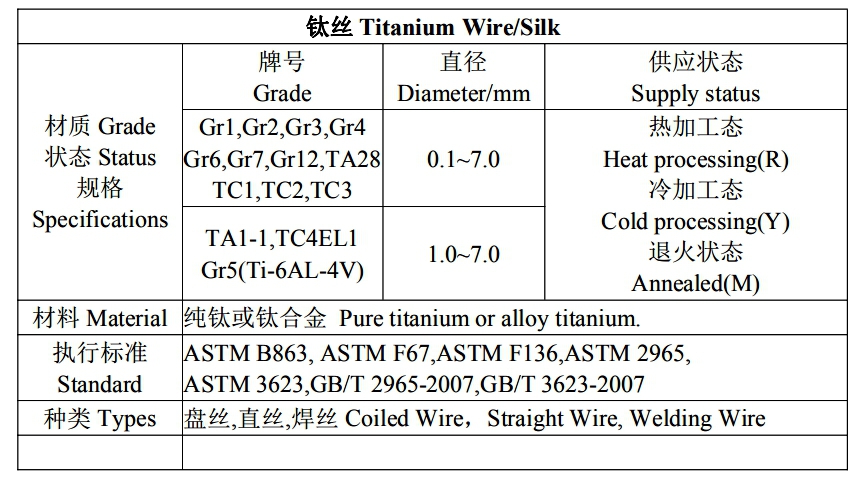

| Dhexroorka Siliga Titanium iyo Noocyada | ||||

| Dhexroorka & Noocyada | ||||

| Dhererka dhexroorka | Noocyada | |||

| mm | inji | Gariiradda | Spool | Toosan |

| 0.05 ilaa 0.78 | 0.002 ilaa 0.031 | Y | Y | N |

| > 0.78 ilaa 3.25 | > 0.031 ilaa 0.128 | Y | Y | Y |

| > 3.25 ilaa 6.00 | > 0.128 ilaa 0.236 | Y | N | Y |

Dulqaadka dhexroorka: +/- 0.05mm (+/- 0.002”) ama ka fiican.Dabaqyada: 100mm - 300mm (3.9 "- 12").Dhererka Toosan: 300mm - 3000mm (12 "- 118")

| Darajo | Tilmaamaha | ||

| AWS A5.16 | ASTM B863 | AMS | |

| Tiitanium Saafi ah oo Ganacsi | ERTi-1,2,3,4 | ASTM B863 Gr1,2,3,4 | AMS 4951 |

| ASTM F67 Gr1,2,3,4 | AMS 4921 | ||

| Ti 6 Al-4V | ERTi-5 | ASTM B863 Gr5 | AMS 4954 |

| Ti 6Al-4V Ceelii | ERTi-5 Eli | ASTM B863 Gr23 | AMS 4956 |

| ASTM F136 Eli | |||

| Ti 0.2 Pd | ERTi-7 | ASTM B863 Gr7 | - |

| Ti 3Al-2.5V | ERTi-9 | ASTM B863 Gr9 | - |

| Ti 0.3Mo-0.8Ni | ERTi-12 | ASTM B863 Gr12 | - |

Halabuurka kiimikada

| Halabuurka (%) | |||||||||||||

| Darajo | Qodobbada ugu muhiimsan | Waxyaabaha wasakhda ah (≤) | |||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | |

| Ta1 | Bal | - | 0.005 | 0.005 | 0.002 | 0.01 | 0.01 | 0.002 | 0.03 | 0.015 | 0.01 | 0.0015 | 0.005 |

| Ta2 | Bal | - | 0.03 | 0.02 | 0.005 | 0.04 | 0.03 | 0.005 | 0.1 | 0.02 | 0.01 | 0.0015 | 0.005 |

| Tanb3 | Bal | 1.5 ilaa 3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | - | 0.02 | 0.01 | 0.005 | 0.01 |

| Tanb20 | Bal | 17.0-23.0 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | - | 0.02 | 0.01 | 0.005 | 0.01 |

| Tanb40 | Bal | 35.0-42.0 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | - | 0.02 | 0.01 | 0.015 | 0.01 |

| Ta2.5W | Bal | - | 0.01 | 0.005 | 0.01 | 2.0 ~ 3.5 | 0.01 | 0.002 | 0.1 | 0.01 | 0.01 | 0.0015 | 0.01 |

| Ta10W | Bal | - | 0.01 | 0.005 | 0.01 | 9.0 ~ 11.0 | 0.01 | 0.002 | 0.1 | 0.015 | 0.01 | 0.0015 | 0. |

Guryaha makaanikada

| Xaalada | Xoog xajin (Mp) | Kordhinta (%) |

| Fudud | 300-750 | 10 ilaa 30 |

| Semi-adag | 750 ilaa 1250 | 1~6 |

| Adag | >1250 | 1~5 |

| TaNb3,TaNb20, sifooyinka farsamada sida ku cad warshadda la cabbiray. | ||

Dulqaadka (mm)

| Dhexroorka | Dulqaad |

| 0.1 ilaa 0.2 | <0.005 |

| 0.2 ilaa 0.5 | <0.007 |

| 0.5 ilaa 0.7 | <0.010 |

| 0.7 ilaa 1.5 | <0.015 |

| 1.5 ilaa 2.0 | <0.020 |

| 2.0 ilaa 3.0 | <0.030 |

| 3.0-4.0 | <0.040 |

Jilicsanaanta Antioxidant

| Darajo | Dhexroorka (mm) | Jajabka Antioxidant Tirada laabashada (≥) |

| Ta1 | 0.10 ilaa 0.40 | 3 |

| >0.40 | 4 | |

| Ta2 | 0.10 ilaa 0.40 | 4 |

| >0.40 | 6 |

Silig gariiradda: dabayl ka dib iyo baakidh leh cudbi luul ah (polyethylene la fidin karo), ka dibna lagu xidhxidhay kiisas alwaax ah.

Silig toosan: Ku xidh siliga tantalum bacaha oo ku rid foosto bac ah oo toosan, ka dibna ku xidh kiis alwaax ah.