Dhuumaha aan Xumaan lahayn

Adag:

Tuubooyinka birta aan-dhalatada lahayn ayaa caadi ahaan loo isticmaalaa in lagu cabbiro adkaanta Brinell, Rockwell iyo Vickers.Qallafsanaanta Brinell Ka mid ah heerarka tuubooyinka birta ah, adkaanta Brinell waa tan ugu ballaaran ee loo isticmaalo, iyo adkaanta walxaha waxaa badanaa lagu muujiyaa dhexroorka gelinta, taas oo ah mid dareen leh oo ku habboon.Si kastaba ha ahaatee, kuma habboona tubooyinka birta ee birta adag ama khafiifka ah.

Rockwell adkaanta:

Tijaabada qallafsanaanta ee Rockwell waxay la mid tahay tijaabada adag ee Brinell.Farqiga u dhexeeya ayaa ah in ay cabbirto qoto-dheeraanta galitaanka.Tijaabada qallafsanaanta Rockwell waa hab si weyn loo isticmaalo kaas oo HRC loo isticmaalo ka labaad kaliya Brinell hardness HB ee heerarka tuubooyinka birta.Adkeysiga Rockwell waxaa lagu dabaqi karaa go'aaminta walxaha birta ah ee aad u jilicsan ilaa aad u adag.Waxay magdhow u tahay habka Brinell.Way ka sahlan tahay habka Brinell waxayna si toos ah u akhrin kartaa qiimaha qallafsanaanta garaaca mashiinka qallafsanaanta.Si kastaba ha ahaatee, galitaanka yar awgeed, qiimaha engegnaanta maaha mid sax ah sida habka Brinell.

adkaanta Vickers

Tijaabada adag ee tuubbada birta ah ee Vickers sidoo kale waa habka tijaabada gelitaanka ee lagu cabbiro walxaha birta ah ee dhuuban iyo adkaanta lakabka sare.Waxay leedahay faa'iidooyinka ugu muhiimsan ee hababka Brinell iyo Rockwell, waxayna ka gudubtaa cilladahooda aasaasiga ah, laakiin ma aha mid fudud sida habka Rockwell.Habka Vickers si dhif ah ayaa loo isticmaalaa heerarka tuubooyinka birta.

Imtixaan adag

Tuubbada birta-la'aanta ah waxay leedahay dhexroor gudaha ah oo ah 6.0mm ama ka badan iyo tuubo bir ah oo la jeexjeexay oo dhumucdiisuna tahay 13mm ama ka yar.Waxay noqon kartaa tijaabiyaha qallafsanaanta nooca W-B75.Waa mid aad u dhakhso badan oo fudud in la tijaabiyo waxayna ku habboon tahay kormeer degdeg ah oo aan burburin oo tuubooyinka birta ah.Tuubooyinka birta aan fiicnayn ee dhexroorkoodu ka badan yahay 30 mm iyo dhumucdiisuna tahay 1.2 mm waxaa lagu tijaabiyaa qalab adag oo Rockwell ah si loo tijaabiyo adkaanta HRB iyo HRC.Tuubooyinka birta aan fiicnayn ee dhexroorkoodu ka badan yahay 30 mm iyo dhumucdiisuna tahay in ka yar 1.2 mm ayaa lagu tijaabiyaa qalabka adag ee Rockwell si loo tijaabiyo adkaanta HRT ama HRN.Tuubooyinka birta ah ee aan lahayn dhexroorka hoose ee ka yar 0 mm kana weyn 4.8 mm, adkaanta HR15T waxaa tijaabiya tijaabiye gaar ah oo adag ee Rockwell ee tuubooyinka.Marka dhexroorka gudaha ee tuubada birta aanu ka weynayn 26 mm, adkaanta gidaarka gudaha ee tuubada waxa sidoo kale tijaabin kara Ro

Halabuurka Kiimikada

| Darajooyinka | C max | Mn max | P max | S max | Si max | Cr | Ni | Mo |

| 304 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-11.00 | / |

| 304L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Guryaha Makaanikada

| Darajooyinka | Shayga | Xasilloonida Psi | Soo saarista Psi | Dheeraad ah % | Rockwell Hardness |

| 304 | La xiray | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | La xiray I1/8 adag | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | La xiray | 85000 min | 35000 min | 50 daqiiqo | 80 daqiiqo |

| La xiray | 80000 min | 30000 min | 50 daqiiqo | 75 min |

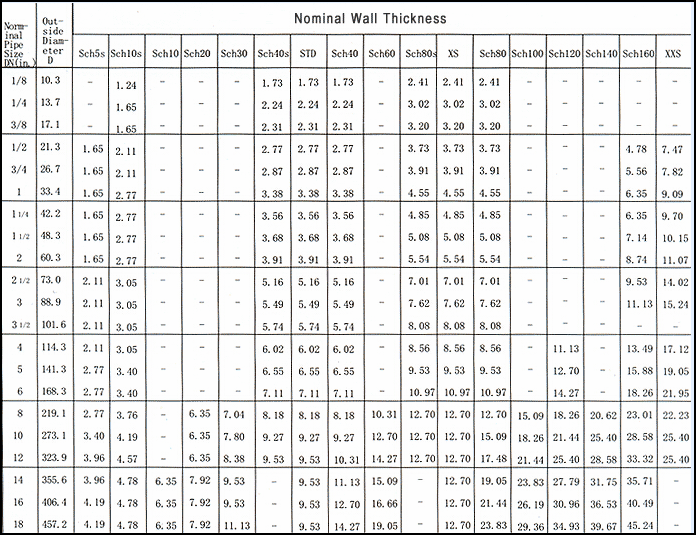

Cabirka Dhuumaha birta ah ee Aanaylahayn

La koolkooliyey & la miiray, koolkoolin dhalaalaya, la safeeyey

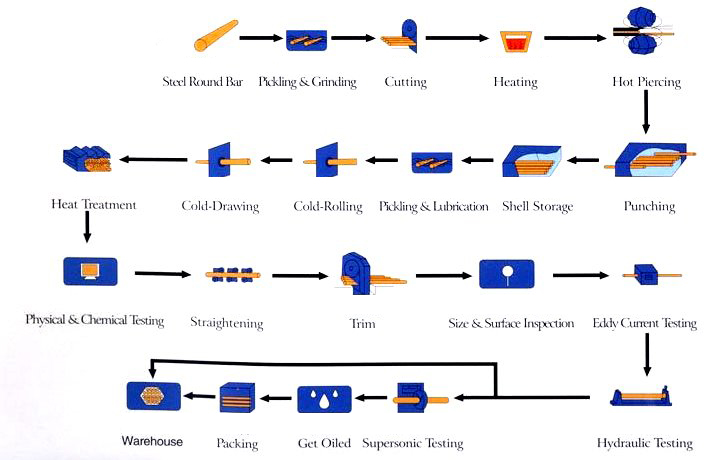

Habka