xusul

Habka Soo saarista Suxulka Aan Xun Lahayn

Mid ka mid ah hababka ugu caansan ee wax soo saarka suxullada waa isticmaalka mandrel kulul foorarsiga tuubooyinka birta toosan.Ka dib marka la kululeeyo tuubada birta ee heerkulka sare, tuubada waa la riixaa, la ballaariyaa, qalloociyaa qalabka gudaha ee mandrel tallaabo tallaabo.Codsashada qaloocinta mandrel kulul soo saari kartaa cabbir ballaaran oo kala duwan oo aan suxul lahayn.Sifooyinka qaloocsanaanta mandrel waxay si xoog leh ugu xiran yihiin qaabka isku dhafan iyo cabbirada mandrel.Faa'iidooyinka isticmaalka suxullada qaloocida kulul waxaa ka mid ah leexasho dhumuc yar iyo leexasho adag oo ka xoog badan nooca kale ee leexinta.Dhanka kale, isticmaalka foorarsiga halkii aad ka ahaan lahayd qaloocyada hore loo sii diyaariyay ayaa si weyn u yaraynaysa tirada alxanka ee loo baahan yahay.Tani waxay yaraynaysaa tirada shaqada ee loo baahan yahay waxayna kordhisaa tayada iyo isticmaalka tubooyinka.Si kastaba ha ahaatee, qaloocinta qabow waa habka loo leexiyo tuubada birta ee tooska ah heerkulka caadiga ah ee mashiinka foorarsiga.Qallooca qabowgu wuxuu ku habboon yahay tuubooyinka leh dhexroorka dibadda ee 17.0 ilaa 219.1 mm, dhumucdiisuna tahay 2.0 ilaa 28.0 mm.Radius-laabashada lagu taliyey waa 2.5 x Do.Caadi ahaan xagasha foorarsiga ee 40D.Isticmaalka qaloocinta qabow, waxaan heli karnaa suxulo yar yar, laakiin waxaan u baahanahay inaan ku xirno gudaha ciidda si aan uga hortagno laalaab.Qalloocinta qabow waa hab foorarsi degdeg ah oo jaban.Waa doorasho tartan u ah samaynta dhuumaha iyo qaybaha mashiinka.

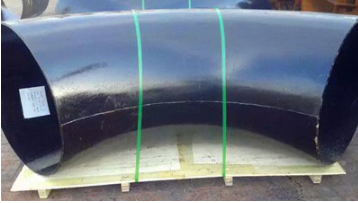

Habka Soo saarista Suxulka alxanka leh (Yar & Weyn)

Suxullada alxanka leh waxaa laga sameeyaa taarikada birta, markaa ma aha xusullada birta ah ee aan xidhnayn.Isticmaal caaryada oo ku cadaadi saxanka birta qaabka suxulka, ka dibna ku ul tollaynta si aad u noqoto xusul bir dhammays tiran.Waa habkii hore ee wax soo saarka suxullada.Sannadihii dhawaa xusullada cabbirrada yaryar waxay ku dhow yihiin in laga soo saaro tuubooyinka birta hadda.Suxullada cabbirka weyn, tusaale ahaan, aad bay u adag tahay in la soo saaro xusullada ka sarreeya 36 "OD ee tuubooyinka birta ah.Markaa waxa caadi ahaan laga sameeyaa taarikada birta, iyadoo saxanka lagu cadaadiyo qaabka suxulka nuska ah, oo la isku alxanayo labada qaybood.Maadaama suxullada ay ku dhex alxanayaan jirkeeda , kormeerka isgoysyada alxanka waa lagama maarmaan .Caadi ahaan waxaanu u isticmaalnaa baadhista raajada NDT ahaan.

| Cabbirka tuubada magacaaban | Dhexroor ka baxsan | Xarun ilaa Dhamaad | Xarunta ilaa Xarunta | Ku laabo Wajiyada | ||||||

| 45° xusullada | 90° xusullada | 180° Soo noqo | ||||||||

| H | F | P | K | |||||||

| DN | INCH | Taxanaha A | Taxanaha B | LR | LR | SR | LR | SR | LR | SR |

| 15 | 1/2 | 21.3 | 18 | 16 | 38 | - | 76 | - | 48 | - |

| 20 | 3/4 | 26.9 | 25 | 16 | 38 | - | 76 | - | 51 | - |

| 25 | 1 | 33.7 | 32 | 16 | 38 | 25 | 76 | 51 | 56 | 41 |

| 32 | 11/4 | 42.4 | 38 | 20 | 48 | 32 | 95 | 64 | 70 | 52 |

| 40 | 11/2 | 48.3 | 45 | 24 | 57 | 38 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 57 | 32 | 76 | 51 | 152 | 102 | 106 | 81 |

| 65 | 21/2 | 76.1 (73) | 76 | 40 | 95 | 64 | 191 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 89 | 47 | 114 | 76 | 229 | 152 | 159 | 121 |

| 90 | 31/2 | 101.6 | - | 55 | 133 | 89 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 108 | 63 | 152 | 102 | 305 | 203 | 210 | 159 |

| 125 | 5 | 139.7 | 133 | 79 | 190 | 127 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 159 | 95 | 229 | 152 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 219 | 126 | 305 | 203 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273.0 | 273 | 158 | 381 | 254 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.9 | 325 | 189 | 457 | 305 | 914 | 610 | 619 | 467 |

| 350 | 14 | 355.6 | 377 | 221 | 533 | 356 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 426 | 253 | 610 | 406 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457.2 | 478 | 284 | 686 | 457 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508.0 | 529 | 316 | 762 | 508 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559 | - | 347 | 838 | 559 | Fiiro gaar ah: | |||

| 600 | 24 | 610 | 630 | 379 | 914 | 610 | ||||

| 650 | 26 | 660 | - | 410 | 991 | 660 | ||||

| 700 | 28 | 711 | 720 | 442 | 1067 | 711 | ||||

| 750 | 30 | 762 | - | 473 | 1143 | 762 | ||||

| 800 | 32 | 813 | 820 | 505 | 1219 | 813 | ||||

| 850 | 34 | 864 | - | 537 | 1295 | 864 | ||||

| 900 | 36 | 914 | 920 | 568 | 1372 | 914 | ||||

| 950 | 38 | 965 | - | 600 | 1448 | 965 | ||||

| 1000 | 40 | 1016 | 1020 | 631 | 1524 | 1016 | ||||

| 1050 | 42 | 1067 | - | 663 | 1600 | 1067 | ||||

| 1100 | 44 | 1118 | 1120 | 694 | 1676 | 1118 | ||||

| 1150 | 46 | 1168 | - | 726 | 1753 | 1168 | ||||

| 1200 | 48 | 1220 | 1220 | 758 | 1829kii | 1219 | ||||

ASTM A234

Qeexitaanku wuxuu daboolayaa birta kaarboonka ee la sameeyay & qalabyada birta daawaha ah ee aan xidhnayn iyo dhismaha alxanka leh.Ilaa dhismo aan xidhnayn ama alxan lahayn loo cayimay siday u kala horreeyaan, midkoodna waxa lagu qalabayn karaa ikhtiyaarka alaab-qeybiyaha.Dhammaan qalabyada dhismaha ee alxanka leh sida ku cad heerkan waxa la keenay 100% shucaaca.Marka loo eego ASTM A234, darajooyin dhowr ah ayaa la heli karaa iyadoo ku xiran qaabka kiimikada.Xulashada waxay ku xirnaan doontaa alaabta tuubada ee ku xiran qalabkan.

| Shuruudaha Xoojinta | WPB | WPC, WP11CL2 | WP11CL1 | WP11CL3 |

| Xoog Jimicsiga, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% la dhimay ama 0.5% kordhin-kordhinta) | [415-585] | [485-655] | [415-585] | [520-690] |

| Xoogga Wax-soo-saarka, min, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |

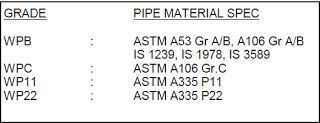

Qaar ka mid ah darajooyinka laga heli karo qeexitaankan iyo qeexida alaabta tuubada ee u dhiganta ayaa hoos ku taxan:

ASTM A403

Qeexitaanku wuxuu daboolayaa laba fasal oo guud, WP & CR, oo ah qalab austenitic ahama ku xidhidhsan oo ah dhismo alxan leh.

Qalabka WP Class waxaa loo soo saaray si waafaqsan shuruudaha ASME B16.9 & ASME B16.28 waxaana loo qaybiyaa saddex dabaqadood sida soo socota:

- WP - Waxaa laga soo saaray alaab aan kala go 'lahayn iyadoo loo marayo habka wax soo saarka.

- WP – W Qalabkani waxa uu ka kooban yahay alxanka iyo dhammaan alxanka ay samaysay soo saaraha ku rakiban oo ay ku jiraan alxanka tuubada bilawga ah haddii tuubada lagu lingaxo oo lagu daro walxo buuxinta ayaa shucaac lagu sawiray.Si kastaba ha ahaatee wax shucaac ah looma samayn alxanka tuubada bilawga ah haddii tuubada la alxanayo iyada oo aan lagu darin walxaha buuxinta.

- WP-WX Qalabyadani waxay ka kooban yihiin alxanka iyo dhammaan alxanka haddii ay sameeyeen soo saaraha qalabaysan ama soo saaraha alaabta bilawga ah waa shucaac.

Qalabyada fasalka CR waxaa loo soo saaray si waafaqsan shuruudaha MSS-SP-43 oo uma baahna baaritaan aan burburin.

Marka loo eego ASTM A403 dhowr darajooyin ayaa la heli karaa iyadoo ku xiran qaabka kiimikada.Xulashada waxay ku xirnaan doontaa alaabta tuubada ee ku xiran qalabkan.Qaar ka mid ah darajooyinka laga heli karo qeexitaankan iyo qeexida alaabta tuubada ee u dhiganta ayaa hoos ku taxan:

ASTM A420

Tilmaamahani waxa uu daboolayaa birta kaarboonka la sameeyay iyo qalabyada birta daawaha ah ee aan xidhnayn iyo kuwa alxanka ah ee loogu talagalay in lagu isticmaalo heerkul hooseeya.Waxay dabooshaa afar darajo WPL6, WPL9, WPL3 & WPL8 taas oo ku xidhan halabuurka kiimikaad.Qalabka WPL6 waxaa lagu tijaabiyay heer kul -50°C, WPL9 at -75°C, WPL3 at -100°C iyo WPL8 at -195°C heerkulka.

Heerarka cadaadiska la oggol yahay ee xirmooyinka waxaa loo xisaabin karaa sida tuubada tooska ah ee aan tooska ahayn iyadoo la raacayo qawaaniinta lagu dejiyay qaybta lagu dabaqi karo ee ASME B31.3.

Dhumucda gidaarka tuubada iyo nooca maaddadu waa inay ahaadaan kuwa lagu amray in la isticmaalo, aqoonsigooda qalabka ku rakiban waa beddelka calaamadaha qiimeynta cadaadiska.

| Birta No. | Nooca | Halabuurka kiimikada | ||||||||||||

| C | Si | S | P | Mn | Cr | Ni | Mo | Mid kale | oob | uus | δ5 | HB | ||

| WPL6 | 0.3 | 0.15-0.3 | 0.04 | 0.035 | 0.6-1.35 | 0.3 | 0.4 | 0.12 | Cb:0.02;V:0.08 | 415-585 | 240 | 22 | ||

| WPL9 | 0.2 | 0.03 | 0.03 | 0.4-1.06 | 1.6-2.24 | 435-610 | 315 | 20 | ||||||

| WPL3 | 0.2 | 0.13-0.37 | 0.05 | 0.05 | 0.31-0.64 | 3.2-3.8 | 450-620 | 240 | 22 | |||||

| WPL8 | 0.13 | 0.13-0.37 | 0.03 | 0.03 | 0.9 | 8.4-9.6 | 690-865 | 515 | 16 | |||||

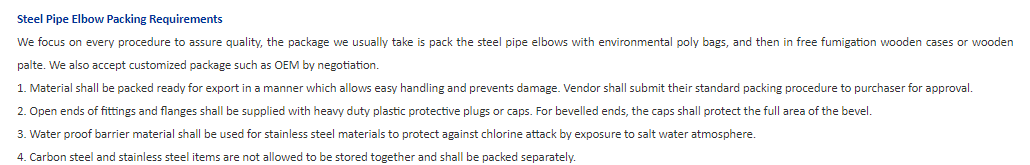

Saliid fudud, Rinjiyeynta Madow, Galvanizing, PE/3PE Dahaarka ka-hortagga daxalka

Waxaa lagu soo badelay Cabin alwaax ah/Saarad alwaax ah