Alloy Dhuumaha aan Xumaan lahayn

OD: 6-720MM

WT: 0.5-120MM

Dhererka: 3-16M

Codsiga: Batroolka, Kiimikada Kiimikada, Korontada, Kuleyliyaha

Heerka:ASTM A335/A335M, ASTM A213/213M, DIN17175-79, JIS3467-88,GB5310-95

Waxyaabaha: P5,T5,P11,P12,STFA22,P22,T91,T9,WB36

Tuubbada Alloy waa nooc ka mid ah tuubooyinka birta ah ee birta ah, waxqabadkeedu aad ayuu uga sarreeyaa tan guud ee birta birta ah, sababtoo ah nooca birta ah waxay ka kooban tahay Cr badan, caabbinta heerkulka sare, caabbinta heerkulka hooseeya, waxqabadka iska caabinta daxalka ayaa aad uga fiican kuwa kale. Dhuumaha birta , sidaas darteed tuubada daawaha waxaa si weyn loogu isticmaalaa batroolka, hawada hawada, kiimikada, korontada, kuleyliyaha, militariga iyo warshadaha kale.

| Alaabta | SEAMLESS / ERW / ARKAY ALLOY TUBE TUBE |

| Cabirka | 6 mm - 1080 mm |

| Dhumucda | 1mm - 135 mm |

| Dhererka | 3 m - 12 m ama sida waafaqsan shuruudaha macaamiisha |

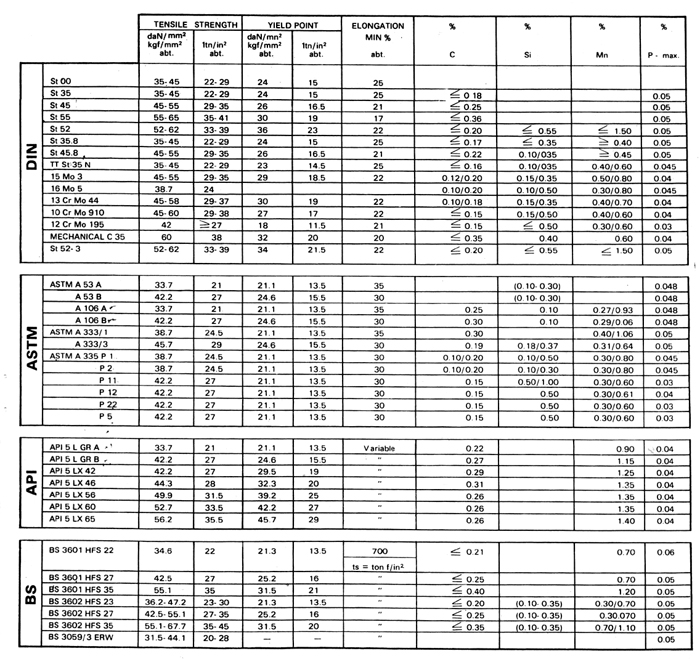

| Heerka | ASTM GB DIN |

| Heerka birta | A106/53/179/214/192/210 A/B/CST37.2/35.4/35.8/52/52.3/52.4/42/4510# 20# 45#P2, P12, P11, P22, P5, P29, P91T , T11, T5,T9,T22, 4140, 12CrMo, 15CrMo, 12Cr2Mo, 1Cr5Mo, 2CrMo4, 1Cr9Mo, 10CrMo910, iwm. |

| Shuruudaha ganacsiga | FOB/CIF/CFR |

| Shuruudaha lacag-bixinta | T/T, L/C |

| Dekadda keenista | Tianjin, Shiinaha |

| Waqtiga dirida | 10 ama marka loo eego tirada dhabta ah ee tuubooyinka |

| Daaweynta dusha sare | Rinjiyeynta madowVarnish rinjiyeynta3PEHot galvanized ama daahan kale sida waafaqsan shuruudahaaga tuuboBare |

| Dhamaadka tuubooyinka | Gariir, bannaan, dun, koofiyadaha caagga ah |

| Kormeer | Baaritaanka ultrasonic, kormeerka maskaxeed, baaritaanka hydrostic iwm. |

| Xidhmada | Xirmooyinka, dabacsan ama si waafaqsan shuruudahaaga |

| Shahaado | API 5L/5CT, ISO, PED iwm. |

Halabuurka Kiimikada

| C,% | Mn, % | P, % | S,% | Si,% | Cr, % | Mo, % |

| 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

Guryaha Makaanikada

| Xoogga Jilbaha, MPa | Xoogga Wax-soo-saarka, MPa | Kordhinta, % |

| 415 min | 205 daq | 30 daqiiqo |

Dhexroorka & Dulqaadka

| ASTM A450 | Kulul duuban | Dhexroorka ka baxsan, mm | Dulqaad, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| Qabow barbaro | Dhexroorka ka baxsan, mm | Dulqaad, mm | |

| OD<25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1<OD<50.8 | ±0.20 | ||

| 50.8≤OD<63.5 | ±0.25 | ||

| 63.5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190.5 | +0.38/-0.64 | ||

| 190.5<OD≤228.6 | +0.38/-1.14 | ||

| ASTM A530 & ASTM A335 | NPS | Dhexroorka ka baxsan, inji | Dulqaad, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

Dhumucda gidaarka & Dulqaadka

| ASTM A450 | Kulul duuban | Dhexroorka ka baxsan, mm | Dulqaad,% |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| Qabow barbaro | Dhexroorka ka baxsan, mm | Dulqaad,% | |

| OD≤38.1 | +20/-0 | ||

| OD>38.1 | +22/-0 | ||

| ASTM A530 | NPS | Dhexroorka ka baxsan, inji | Dulqaad,% |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

ASTM A335 oo loogu talagalay Dhuumaha Birta-Ferritic Alloy-Steel ee Adeegga Heerkulka Sare

ASTM A519- loogu talagalay kaarboonka iyo birta daawaha ee tuubooyinka makaanikada ah ee aan cillad lahayn

ASTM A213- loogu talagalay Ferritic iyo Austenitic Alloy-Steel Boiler, Kuleyliyaha Sare, iyo Tubooyinka Kulaylka

ASTM ASME (S) A-335/(S)A-335M Darajada iyo Halabuurka Kiimikada

| Darajo | UNS | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| P1 | K11522 | 0.10-0.20 | 0.30-0.80 | 0.025 | 0.025 | 0.10-0.50 | - | 0.44 ~ 0.65 |

| P2 | K11547 | 0.10-0.20 | 0.30-0.61 | 0.025 | 0.025 | 0.10-0.30 | 0.50 ~ 0.81 | 0.44 ~ 0.65 |

| P5 | K41545 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 | 4.00 ~ 6.00 | 0.44 ~ 0.65 |

| P5b | K51545 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.00 ~ 2.00 | 4.00 ~ 6.00 | 0.44 ~ 0.65 |

| P5c | K41245 | 0.12 | 0.30-0.60 | 0.025 | 0.025 | 0.50 | 4.00 ~ 6.00 | 0.44 ~ 0.65 |

| P9 | S50400 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 ~ 1.00 | 8.00-10.00 | 0.44 ~ 0.65 |

| P11 | K11597 | 0.05-0.15 | 0.30-0.61 | 0.025 | 0.025 | 0.50 ~ 1.00 | 1.00 ~ 1.50 | 0.44 ~ 0.65 |

| P12 | K11562 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 | 0.80 ~ 1.25 | 0.44 ~ 0.65 |

| P15 | K11578 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.15 ~ 1.65 | - | 0.44 ~ 0.65 |

| P21 | K31545 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 | 2.65 ~ 3.35 | 0.80 ~ 1.60 |

| P22 | K21590 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 | 1.90 ~ 2.60 | 0.87 ~ 1.13 |

| P91 | K91560 | 0.08-0.12 | 0.30-0.60 | 0.020 | 0.010 | 0.20-0.50 | 8.00-9.50 | 0.85 ~ 1.05 |

| P92 | K92460 | 0.07-0.13 | 0.30-0.60 | 0.020 | 0.010 | 0.50 | 8.50-9.50 | 0.30-0.60 |

Fiiro gaar ah: (S) A335 P91 ka kooban kiimiko kale waa: V 0.18 ~ 0.25;N 0.030 ~ 0.070;Ni≤0.40;Al≤0.04;Nb 0.06 ~ 0.10

(S) A335 P92 kale oo ka kooban kiimiko waa: V 0.15 ~ 0.25;N 0.030 ~ 0.070;Ni≤0.40;Al≤0.04;Nb 0.04 ~ 0.09;W 1.5 ~ 2.00;B 0.001 ~ 0.006

Daahan madow, saliid / varnish, FBE, 2PE, 3PE, galvanized iwm Faahfaahin baakad: Xirmooyinka xirmooyinka ama shuruudaha macmiilka