Dhuumaha Qodista Miisaanka Culus

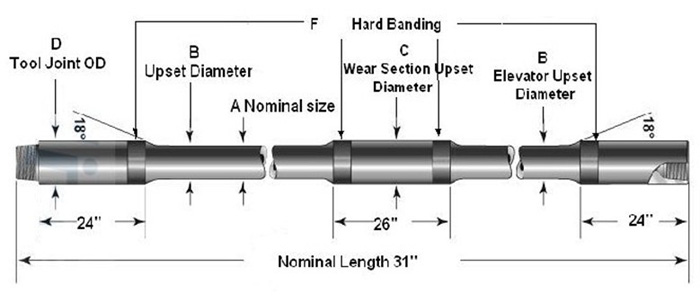

Tuubbada daloolista ee isku-dhafan ee miisaanka culus waa aagga kala-guurka ee u dhexeeya tuubada daloolista iyo tuubada daloolista.Ma yarayn karto oo keliya samaynta walbahaarka ee isku xirka collar iyo tuubada daloolista, laakiin sidoo kale waxay yareyn kartaa xirashada OD.

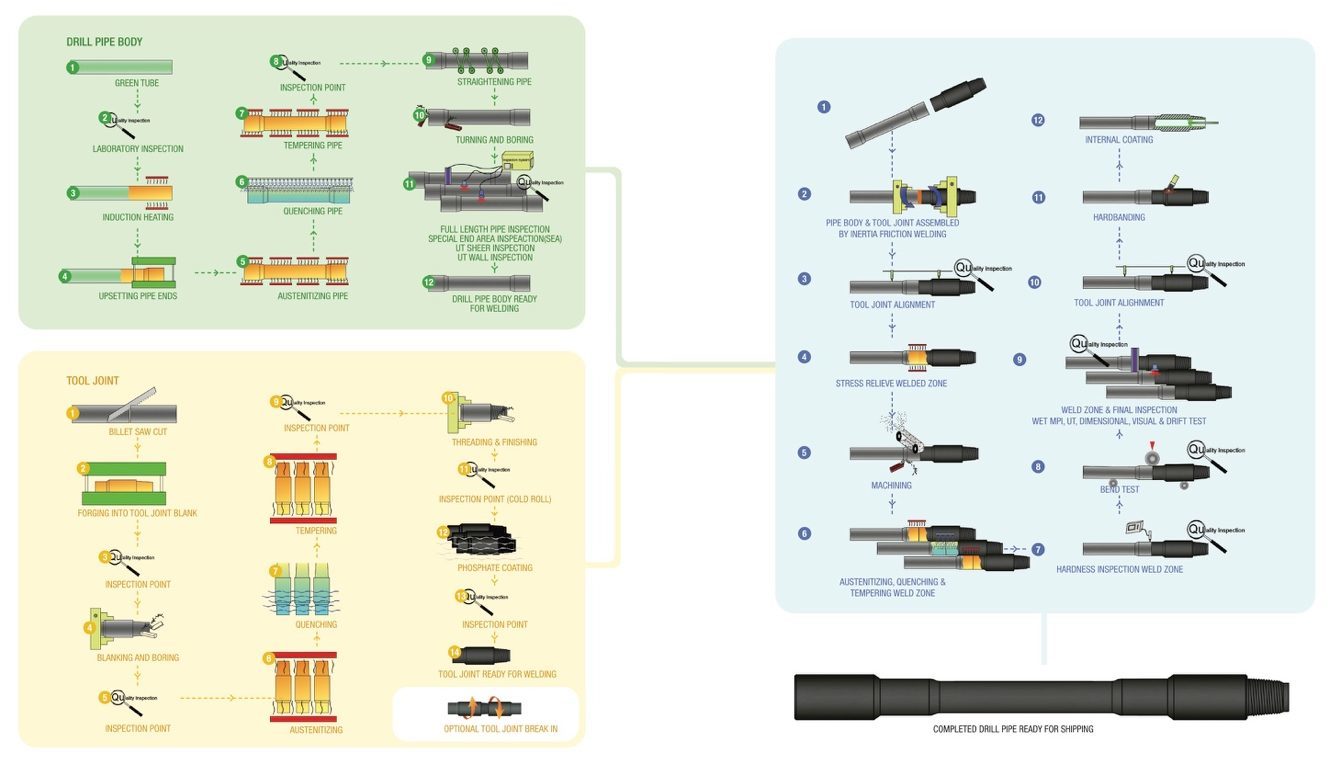

Dhuumaha feeraha culus ee isku dhafka ah ayaa laga sameeyay hal gabal oo AISI 4145H bar adag ah, kulayl si buuxda loo daweeyay, dhammaan sifooyinka jireed waxay waafaqsan yihiin API spec7 daabacaadda ugu dambeysay.

Xirmada HWDP ee iska caabbinta adag ee xidhidhisku waa halbeeg ku saabsan xidhiidhada kala goysyada qalabka iyo xanaaqa dhexe.Noocyada xargaha adag waxaa ka mid ah Arnco 100XT iyo 100XT.Dhammaan dunta waa fosfat, copperized ama qabow la shaqeeyay.Xidhiidhada oo dhan waxay ku qalabaysan yihiin ilaalinta dunta birta ah ee la riixay.Dhammaan xayaysiisyada waxaa lagu farsameeyay shaandhada CNC-Laba-garabka iyo dunta gaarka ah.

Tilmaamaha farsamada iyo xuduudaha

| Cabbirka | OD (gud) | Aqoonsiga (gudaha) | Qalabka Wadajirka ah ee OD (gu jira) | Aqoonsiga wadajirka ah ee aaladda | Isku xirka | Dhexroorka wiishka ugu sarreeya (gudaha) | Central xanaaqa dia.(gud) | Min.drift dia.size(in) |

| 3 1/2 | 3 1/2 | 2 1/4 | 4 3/4 | 2 1/4 | NC38 | 3 7/8 | 4 | 2 |

| 2 1/16 | 2 1/16 | 1 13/16 | ||||||

| 4 | 4 | 2 1/2 | 5 1/4 | 2 1/2 | NC40 | 4 3/16 | 4 1/2 | 2 1/4 |

| 2 9/16 | 2 9/16 | 2 5/16 | ||||||

| 4 1/2 | 4 1/2 | 2 11/16 | 6 1/4 | 2 11/16 | NC46 | 4 11/16 | 5 | 2 7/16 |

| 2 3/4 | 2 3/4 | 2 1/2 | ||||||

| 2 13/16 | 2 13/16 | 2 9/16 | ||||||

| 5 | 5 | 3 | 6 5/8 | 3 | NC50 | 5 1/8 | 5 1/2 | 2 3/4 |

| 5 1/2 | 5 1/2 | 3 1/4 | 7 | 3 1/4 | 5 1/2 FH | 5 11/16 | 6 | 3 |

| 3 3/8 | 3 3/8 | 3 1/8 | ||||||

| 3 7/8 | 3 7/8 | 3 5/8 | ||||||

| 4 | 4 | 3 3/4 | ||||||

| 6 5/8 | 6 5/8 | 4 | 8 | 4 | 6 5/8 FH | 6 15/16 | 7 1/8 | 3 3/4 |

| 4 1/2 | 4 1/2 | 4 1/4 | ||||||

| 5 | 5 | 4 3/4 |

| Tuubbada daloolista miisaanka culus ee Spiral | ||||||||

| Tilmaam mm | Tube | Wadajir | ||||||

| Aqoonsiga mm | Wiishka xanaaqsan | jeexdin wiishka /Sub ka baxsan dhexroormm | Ku dhaji dhexroor mm | Spiral jeexdin qoto dheer | Nooca dunta | OD mm | Aqoonsiga mm | |

| 88.9 (3 1/2) | 54 | 92.1 | 88.9 | 101.6 | 9.5 | NC38 | 120.6 | 54 |

| 114.3 (4 1/2) | 69.8 | 117.5 | 114.3 | 127 | 12.7 | NC46 | 158.8 | 69.8 |

| 127.0 (5) | 76.2 | 130.2 | 127 | 139.7 | 12.7 | NC50 | 165.1 | 76.2 |

| Calaamadda Birta | Halabuurka Kiimikada% | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Al | |

| 4145H | 0.42~0.48 | 0.15~0.35 | 0.90~1.20 | ≤0.03 | ≤0.03 | 0.90~1.20 | 0.15~0.25 | ≤0.2 | 0.025~0.045 |

| Qaybaha Kale:N≤0.015,Ni≤0.5 | |||||||||

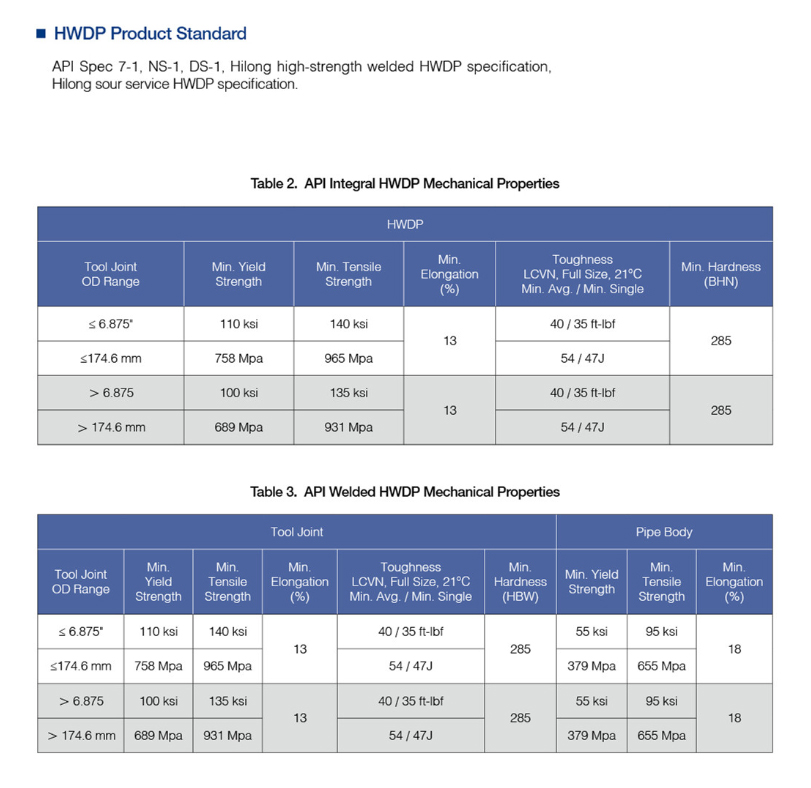

| Codsiga | Qalab | Cabbirka | Xoogga Wax-soo-saarka (min KSI) | Xoogga ugu dambeeya (min KSI) | Hardness Brinell (HB) | Kordhinta (A%) | Min CHarpy (ft-lbs @+20°C) |

| Halbeegga Isku-dhafan | AISI 4145H wax laga beddelay | Dhammaan | 110 | 140 | 285 ilaa 340 | 13 | 40 |

| Heerka alxanka | AISI 1340 wax laga beddelay | Dhammaan | 65 | 95 | 235 (ugu badnaan) | 18 | 30 |

| Welded NS-1 | AISI 4140H wax laga beddelay | Dhammaan | 120 | 140 | 285 ilaa 340 | 13 | 40 |

| Heerka alxanka | AISI 4140H wax laga beddelay | Ka sarreeya 7 1/4" | 120 | 140 | 285 ilaa 340 | 13 | 40 |

| Heerka alxanka | AISI 4140H wax laga beddelay | Ilaa 7 1/4" | 100 | 135 | 285 ilaa 340 | 13 | 40 |

| HWDP-110 HW MS | ASCOWELL C | Ka sarreeya 6 3/4" | 110 | 140 | 285 ilaa 340 | 13 | 0 |

| HWDP-110 HW MS | ASCOWELL C | Ilaa 6 3/4" | 100 | 135 | 285 ilaa 340 | 13 | 55 |

| HWDP-65 HW MS (qalabka wadajirka ah) | ASCOWELL C | Ka sarreeya 6 3/4" | 110 | 140 | 285 ilaa 340 | 13 | 55 |

| HWDP-65 HW MS (qalabka wadajirka ah) | ASCOWELL C | Ilaa 6 3/4" | 100 | 135 | 285 ilaa 340 | 13 | 55 |

| HWDP-65 HW MS | AISI 1340 wax laga beddelay | Dhammaan | 65 | 95 | 235 (ugu badnaan) | 18 | 30 |