Dhuumaha Birta Kaarboon ee aan Xumaan lahayn

Dhuumaha birta ah ee aan cillad lahayn waxaa laga sameeyaa bir wareegsan oo adag'billet'kaas oo la kululeeyo oo la riixo ama lagu jiido foom ilaa birta loo qaabeeyo tuubo godan.Tuubbada bilaa-xun ayaa markaa lagu dhammeeyaa cabbirka iyo dhumucda gidaarka cabbirrada min 1/8 inch ilaa 32 inch OD.Tuubooyinka Birta Kaarboonka ee aan Xumaan lahayn/tuubyada Birta Kaarboonku waa daawaha ka kooban bir iyo kaarboon.Boqolkiiba kaarboonka ku jira birta waxay saamaysaa adkaanta, xoogga bartinimada iyo ductility birta kaarboonka.Dhuumaha birta kaarboonka ah ee aan xumi lahayn ama birta adag ee birta ah ayaa laga sameeyaa tuubada xididka ee daloolka dhex mara, ka dibna waxaa la soo dhex maraa kulaylka, duuban qabow ama qabow.Dhuumaha birta kaarboonka ee aan kala go 'lahayn ee warshadaha birta ee Shiinaha ayaa leh boos muhiim ah.Walaxda tuubada kaarboonka ee birta ah ee aan xumi lahayn waa tuubo wareegsan, mishiinka goynta tuubada embriyaha si ay u dhex maraan jarista ilaa 1 mitir oo dherer ah oo maran, oo ay soo dirto kulaylinta foornada suunka qaada.Billet waxaa lagu quudiyaa foornada kuleylka, heerkulku waa qiyaastii 1200 darajo Celsius.Shidaalku waa hydrogen ama acetylene.Xakamaynta heerkulka foornada ayaa ah arrinta ugu muhiimsan.Tuubo wareeg ah ayaa u soo baxday si ay u feero mashiinka cadaadiska hawada.Guud ahaan feerka caadiga ah waa mashiinka daloolka duudduuban ee duuban, feer waxtarka wax soo saarka sare, tayada wax soo saarka, ballaadhinta dalool dhexroor weyn, xiran kara noocyo kala duwan oo bir ah.Daloolin, tubbada wareegsan waxay dul saarnayd rogaal-celinta saddex-rogadka ah, duubista ama extrusion.Tuubada ayaa laga tuujiyay cabirka kadib.Ku cabbirida daloollada koofiyada rotary ee xawaaraha sarreeya ee biilka si loo sameeyo tuubo.Dhexroorka tuubada iyadoo loo eegayo mishiinka cabbirka si loo go'aamiyo dhererka dhexroorka daloolka.Kadib tuubada dhexda cabbirka ilaa munaaradda qaboojinta, qaboojinta buufinta biyaha, birta qaboojinta ka dib, waa inay toosisaa.Ka dib markii suunka birta loo diro toosinta mishiinka tijaabada birta (ama tijaabada cadaadiska) ee tijaabada gudaha.Haddii dhuumaha gudaha dillaaco, xumbo iyo dhibaatooyin kale ayaa la ogaan doonaa.Ka dib tuubada laakiin sidoo kale iyada oo loo marayo xulashada buug-gacmeedka tayada adag.Tayada birta, isticmaalka nambarada rinjiga buufinta, qeexitaannada, tirada badan ee wax soo saarka.By wiish galay bakhaarka.

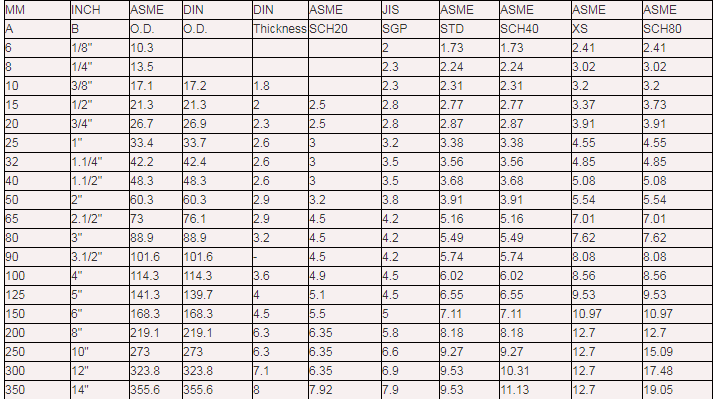

Dhumucdiisuna waxay tahay dhumucdiisuna waxay tahay tuubo aan lahayn

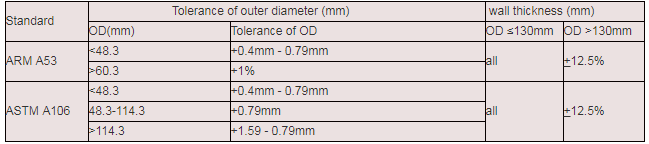

Dulqaadka dhexroorka dibadda iyo dhumucda gidaarka

| Heerka | Sharaxaada |

| ASTM A179/A179M | Qabow aan kala go 'lahayn oo dheesha kulaylka birta alloy hooseeya iyo tuubooyinka qaboojiyaha. |

| API 5L | Dhuumaha khadka. |

| ASTM A53M | Madow & Zinc Dahaar Alxan leh iyo Dhuumaha Birta aan Xumaan lahayn. |

| ASTM A106M | Dhuumaha birta kaarboonka ee aan cillad lahayn ee adeega heerkulka sare. |

| ASTM A105M | Foornada birta kaarboon ee codsiyada tuubooyinka |

| ASTM A234M | Tuubbooyinka birta kaarboonka la sameeyay iyo birta daawaha ah ee loogu talagalay adeegga heerkulka dhexdhexaadka ah iyo sare. |

| ASTM 3799 | Xirmooyinka tuubooyinka birta, maroojisyada iyo alxanka godka ee warshadaha batroolka. |

| AS 1163 | Qaybaha godan ee birta qaab dhismeedka |

| AS 1074 | Tuubooyinka birta iyo tuubooyinka loogu talagalay adeegga caadiga ah |

| BS13872 | Tuubo bir ah oo la maroojiyey oo la jeexjeexay iyo tuubooyin |

| Heerka | Nooca tuubada | Fasalka | Darajo |

| API SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q

| ||

| PLS2 Deegaanka dhanaan | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| WELD | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Heerka | Darajo |

| ASTM A53 M | A, B |

| ASTM A106M | A, B, C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Darajo: Halabuurka Kiimikada (%):

| Heerka | Darajo | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G 3454 | STPG 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| JIS G 3456 | TALLAABADA 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| TALLAABADA 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STPT 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Daaweynta dusha sare ee dhuumaha birta: Si loo hagaajiyo nolosha adeegga dhuumaha saliidda, daaweynta dusha sare waxaa sida caadiga ah loo sameeyaa si loo fududeeyo isku-dhafka adag ee tuubada birta iyo daahan anticorrosive. Hababka processing ee caadiga ah waa: nadiifinta, derusting qalab, pickling, rasaas qarxinta derusting. afar qaybood.1 nadiifinta Dufan, boodhka, saliidaha, walxaha organic ku dhejisan dusha sare ee tuubada birta, sida caadiga ah iyadoo la isticmaalayo dareeraha, emulsion si loo nadiifiyo dusha sare. Si kastaba ha ahaatee, miridhku, maqaarka oxide iyo alxanka dusha sare ee tuubada birta lama saari karo, sidaas darteed kuwa kale Hababka daawaynta ayaa loo baahan yahay.Qalabka miridhku ka saarida oxide dusha sare ee biibiile, miridhku, alxanka, waxay isticmaali kartaa burushka siliga birta si aad u nadiifiso oo u nadiifiso daweynta dusha sare Qalabaynta qalabka waxay gaari kartaa heerka Sa3. Haddii dusha sare ee tuubada birta ay ku xiran tahay maqaarka oksidheer gaar ahaan xooggan, waxaa laga yaabaa in aan macquul ahayn in laga saaro miridhku iyadoo la kaashanayo qalabka, markaa waxaan u baahanahay inaan helno siyaabo kale.3 pickling hababka caadiga ah ee pickling waxaa ka mid ah kiimiko iyo electrolysis. Laakiin kaliya pickling kiimikaad ayaa loo isticmaalaa ilaalinta daxalka dhuumaha la toogtay (cammuud) ka dib dib u habaynta.4 xabbad qarxin ah oo ka saarista miridhku by matoor awood sare wad xawaaraha-xawaaraha sare ee garbaha wareega, birta birta, toogashada birta, qaybta, macdanta iyo silig kale oo abrasive hoos tilmaanta ficilka centrifugal xoog buufin dusha birta birta iyo saarista tirada badan, si fiican ka saar miridhku, oxides iyo wasakh hal dhinac, dhinaca kale, bir bir ah oo hoos timaadda ficilka saamaynta rabshadaha abrasive iyo xoog is jiid jiid, si loo gaaro roughness labis loo baahan yahay.Among afarta hababka daaweynta, qarxinta rasaasta iyo derusting waa hab daaweyn ku habboon derusting tuubada.Guud ahaan, qarxinta rasaasta iyo dildilaaca ayaa inta badan loo isticmaalaa daawaynta gudaha gudaha ee tuubada birta, iyo qarxinta rasaasta iyo burburinta ayaa inta badan loo isticmaalaa daawaynta dusha sare ee tuubada birta.

Rinjiga buufin

Rinjiga buufin

Baakadaha aan biyuhu lahayn