ASTM A335 Dhuumaha Birta

| Magaca Alaabta | Alloy Steel Dhuumaha |

| Qalab | Alloy Steel |

| Dhererka Dhuumaha | Dhererka Random-ka Keliya iyo Dhererka random-ka labanlaaban.SRL:3M-5.8M DRL:10-11.8M ama Sida ay macaamiishu codsadeen dherer |

| Cabbirka | Xajmiga 1/4”ilaa 24”Dhexroor ka baxsan 13.7 mm ilaa 609.6 mm |

| Dhumucda gidaarka | SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100 SCH120, SCH160, XS, XXS |

| Heerka | ASTM A 335 Fasalka P1, P2, P5, P9, P9A, P11, P22.ASTM A213 T1B, T1, T2, T5, T9, T9A, T11, T12, T22.A199 T5, T9, T11, T22.BS 3604 621, 622, 625, 629-470, 629-590, 660, 762.DIN 17175 15 Mo 3, 13 Cr Mo 44, 10 Cr Mo 910, 14 Mo V 63, X 20 Cr Mo V 123 , 620-460, 622-490, 629-470, 629-590, 762. JISG3458/G3462/3467 iyo DIN17175-79. |

| Codsiyada | 1.tuubo dareere ah 2. Warshada Korontada 3. Dhuumaha qaab dhismeedka 4. Cadaadis sare iyo mid hooseeya tuubada kululeeyaha 5. Tuubooyinka birta ah ee aan kala go'a lahayn ee dildilaaca batroolka 6. Dhuumaha dhuunta 7. Tuubooyinka qashinka lagu sameeyo ee dawooyinka iyo dhismaha maraakiibta iwm |

| Shahaado | ISO/PED/TUV/SGS/LR/BV |

| Suuqa Weyn | Aasiya, Bariga Dhexe, Yurub, Ameerika, Afrika, Australia, iwm |

Halabuurka Kiimikada(%):

| Darajo | Magacaabidda UNS | Halabuurka,% | |||||||

| Kaarboon | Manganese | Fosfooraska, | Baaruud | Silikoon | Chromium | Molybdenum | Kuwo kale | ||

| max | max | ||||||||

| P1 | K11522 | 0.10-0.20 | 0.30-0.80 | 0.025 | 0.025 | 0.10-0.50 | - | 0.44–0.65 | - |

| P2 | K11547 | 0.10-0.20 | 0.30-0.61 | 0.025 | 0.025 | 0.10-0.30 | 0.50-0.81 | 0.44–0.65 | - |

| P5 | K41545 | 0.15 max | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 4.00-6.00 | 0.45–0.65 | - |

| P9 | S50400 | 0.15 max | 0.30-0.60 | 0.025 | 0.025 | 0.25-1.00 | 8.00-10.00 | 0.90-1.10 | - |

| P11 | K11597 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50-1.00 | 1.00-1.50 | 0.44–0.65 | - |

| P12 | K11562 | 0.05-0.15 | 0.30-0.61 | 0.025 | 0.025 | 0.50 max | 0.80-1.25 | 0.44–0.65 | - |

| P15 | K11578 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.15–1.65 | - | 0.44–0.65 | - |

| P21 | K31545 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 2.65–3.35 | 0.80–1.06 | - |

| P22 | K21590 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 1.90-2.60 | 0.87–1.13 | - |

| P23 | K41650 | 0.04–0.10 | 0.10-0.60 | 0.03 | 0.01 | 0.50 max | 1.90-2.60 | 0.05-0.30 | V 0.20-0.30 |

| Cb 0.02–0.08 | |||||||||

| B 0.0005-0.006 | |||||||||

| N 0.030 max | |||||||||

| Al 0.030 max | |||||||||

| W 1.45–1.75 | |||||||||

| P91 | K91560 | 0.08-0.12 | 0.30-0.60 | 0.02 | 0.01 | 0.20-0.50 | 8.00-9.50 | 0.85–1.05 | V 0.18-0.25 |

| N 0.030-0.070 | |||||||||

| Ni 0.40 max | |||||||||

| Al 0.04 max | |||||||||

| Cb 0.06–0.10 | |||||||||

| P92 | K92460 | 0.07-0.13 | 0.30-0.60 | 0.02 | 0.01 | 0.50 max | 8.50-9.50 | 0.30-0.60 | V 0.15-0.25 |

| N 0.03–0.07 | |||||||||

| Ni 0.40 max | |||||||||

| Al 0.04 max | |||||||||

| Cb 0.04–0.09 | |||||||||

| W 1.5-2.00 | |||||||||

| B 0.001-0.006 | |||||||||

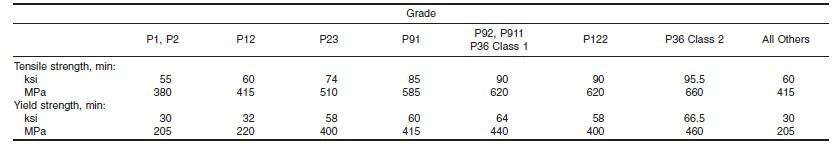

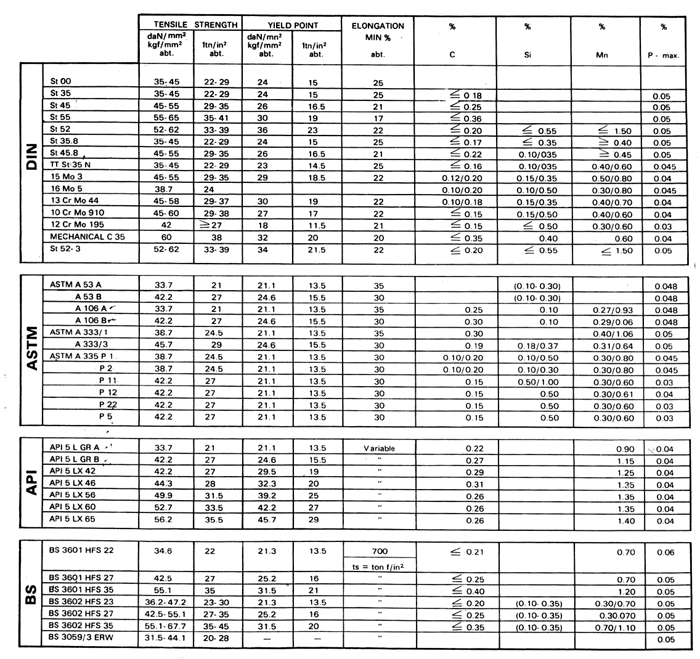

Guryaha Makaanikada:

Daahan madow, saliid / varnish, FBE, 2PE, 3PE, galvanized iwm Faahfaahin baakad: Xirmooyinka xirmooyinka ama shuruudaha macmiilka