Dhuumaha qamadiga ah

Tuubooyinka daasadaha ah ee loo isticmaalo sahaminta saliidda waxay ka hortagi karaan 99% ciidda, hoos u dhigi karaan 80% saliidda si fiican dayactirka culus, iyo sidoo kale kordhinta xoogga ceelka saliidda, isdhexgalka iyo xasilloonida ka ilaalinta ciidda.Dhanka kale, farsamada jeexida laysarka ayaa ka dhigi karta booska mid siman oo sax ah.Qaab dhismeedka tuubbada dacas ee daloolku waa muunad, laakiin si heersare ah ayey u shaqeysaa.

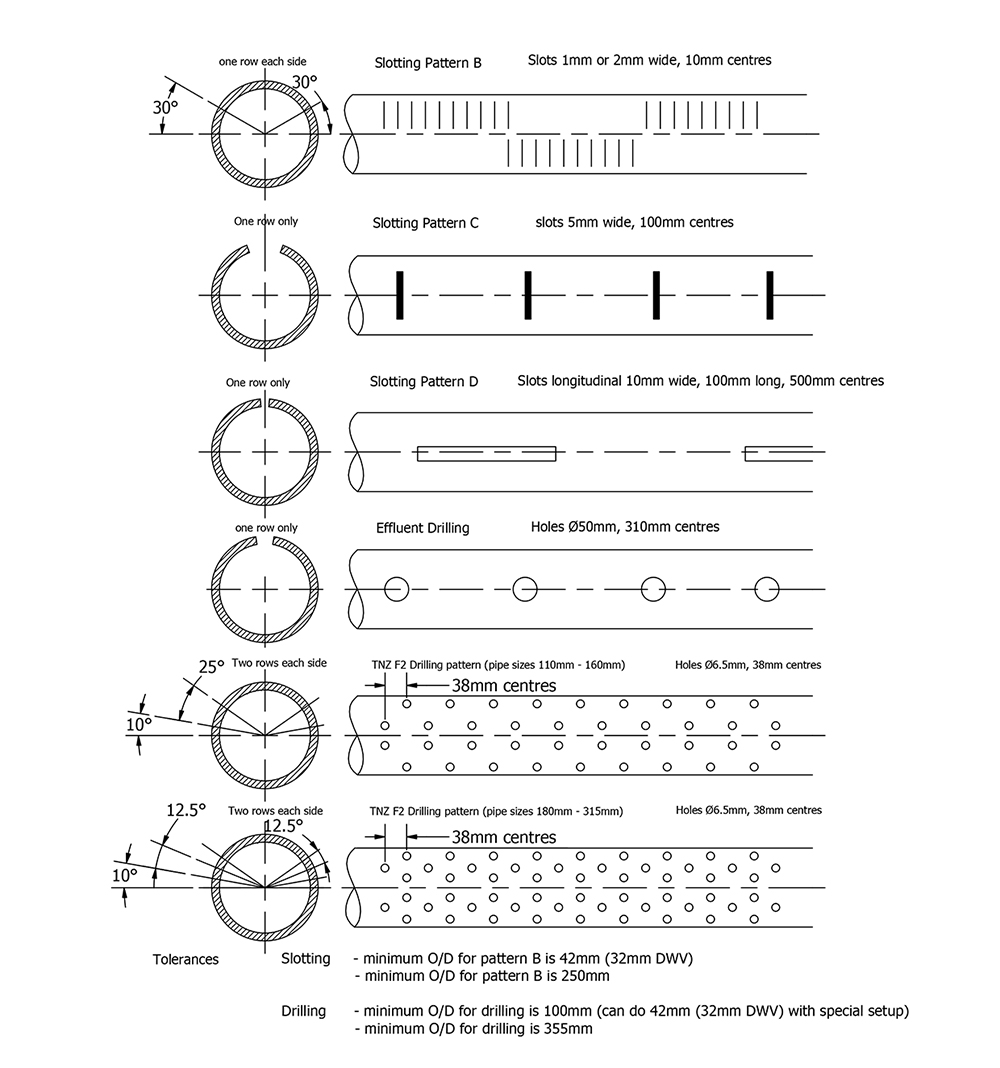

Processing tube Slotted waa on jidhka bir xoog sare leh habab shaqo qabow ama kulul, jarida baxay boqolaal kun oo dildilaaca dhaadheer, dildilaaca sida caadiga ah loo isticmaalo qeexida: tollayn width 0.15 3 mm, xataa dheeraad ah oo ballaaran, dhererka farqiga 50-200 mm.Cross qaybta noocyada waa: leydi, sallaan qaabeeya, gaar ah oo kala duwan, sidoo kale waxa uu leeyahay shaashadda jeexdin wareeg ah, dhexroorka daloolka caddaymaha kala duwan 5-20 mm in mitir. qaybta qaabaynta darajada hagaagsan, oo ku taal cidhifka daloolka jilicsanaanta iyo heerka caabbinta daxalka ee tolitaanka daloolka.

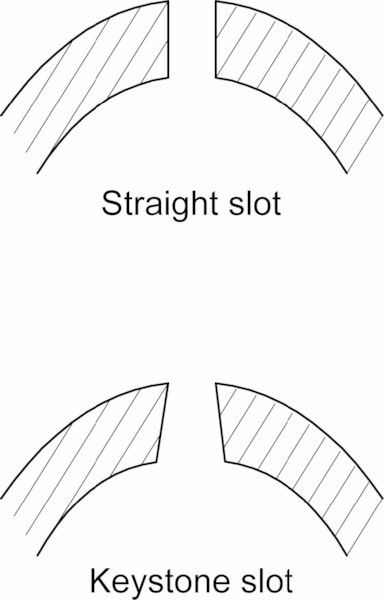

Afyare toosan-Boodhadhka waxaa lagu gooyaa ballac siman iyadoo loo sii marayo gidaarka tuubada ID iyo OD labadaba.Lagu cayimay halka isku xidhka hadhuudhka ciidda ee booska aanu ahayn muhiimad weyn, boosaska toosan ayaa aad uga adkaysi badan marka loo eego godadka furaha ee la tolay waana kharash yar in la soo saaro.Codsiyada caadiga ah ee boosaska goynta Toosan waxaa loogu talagalay Soosaarka Qabow iyo ceelasha jiifka ee CBM marka lagu daro ceelasha injector ee SAGD.

Naadi Keystone Seamed--waa lagu shiiday si ka sii ballaadhan tuubada gudaha oo ay is-dajiyaan si ay uga hortagaan in la xidho.Cidhiidhi ah oogada xayndaabka iyo korodhka ballaca gudaha, waxay u oggolaadaan ciidda soo gasha inay si fudud u dhex marto meelaha bannaan iyada oo aan la xidhin.

| API Casing pipe | ID | Dhererka | Dhererka Slot | Afyare No. | Ballaca Slot | Slot | Shaandhee sax ah | Max. | ||

| Spec mm | Dhumucda | Halkii Miisaanka | ||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

| 88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

| 101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

| 127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

| 139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

| 9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

| 168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

| 177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

| 9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

| Cabbirka dhuumaha shaashadda (gudaha) | OD (mm) | Dhumucda gidaarka (mm) | Aqoonsiga (mm) | Tirada tolmada goobabada kasta | Ballaca godka (mm) | Dhererka booska (mm) | Dhererka (mm) |

| 2-3/8" | 60.3 | 4.83 | 50.64 | 12 ~ 18 | 0.2 ~ 0.8 | 45-100 | 1000-12000 |

| 2-7/8" | 73 | 5.51 | 61.98 | 20 ~ 24 | 45-100 | ||

| 3-1/2 " | 88.9 | 6.45 | 76 | 24 ~ 28 | 45-100 | ||

| 4 " | 101.6 | 6.65 | 88.29 | 24 ~ 30 | 45-100 | ||

| 4-1/2 " | 114.3 | 5.69 | 102.92 | 24 ~ 30 | 45-100 | ||

| 6.35 | 101.6 | 45-100 | |||||

| 7.37 | 99.57 | 45-100 | |||||

| 8.56 | 97.18 | 45-100 | |||||

| 5 " | 127 | 5.59 | 115.82 | 28 ~ 36 | 0.25 ~ 0.8 | 45-100 | |

| 6.43 | 114.15 | 45-100 | |||||

| 7.52 | 111.96 | 45-100 | |||||

| 9.19 | 108.61 | 45-100 | |||||

| 5-1/2 " | 139.7 | 6.2 | 127.3 | 30 ~ 38 | 45-100 | ||

| 6.99 | 125.73 | 45-100 | |||||

| 7.72 | 124.26 | 45-100 | |||||

| 9.17 | 121.36 | 45-100 | |||||

| 10.54 | 118.62 | 45-100 | |||||

| 7 " | 177.8 | 6.91 | 163.98 | 36 ~ 50 | 45-100 | ||

| 8.05 | 161.7 | 45-100 | |||||

| 9.19 | 159.41 | 45-100 | |||||

| 10.36 | 157.07 | 45-100 |

1. Dhuumahayaga daloolsan waxay isticmaalaan daasadaha J55/K55/N80 iyo tuubooyinka heerka API, oo leh xoog guud oo sarreeya, ma fududa in la qalloociyaa.

2. Cidhifka boosku waa toosan, siman, oo aan lahayn burs, booskuna waa isku mid.

3. Dhuumaha daloolku waxay ku habboon yihiin ceel cammuud ah, kaas oo dhexroorka ciidda ka weyn yahay 0.3mm.

4. Boosku wuxuu noqon karaa mid dheer oo leexleexan, qaybta boosku waxay noqon kartaa mid isku mid ah iyo noocyo trapezoidal ah, oo leh aag ballaaran oo furan.

5. Dhuumaha shaashadda ee la go'ay waxay leedahay dhexroor weyn oo gudaha ah.

API Spec 5CT-Tilmaamaha 5CT/ISO 11960, Caddadka Sideedaad, Warshadaha Batroolka iyo Gaaska Dabiiciga ah-Tubbooyinka birta ah ee loo isticmaalo daasadaha ama tuubooyinka ceelasha

| Heerka | Darajo | Halabuurka kiimikaad () | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34 ilaa 0.39 | 0.20 ilaa 0.35 | 1.25 ilaa 1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34 ilaa 0.38 | 0.20 ilaa 0.35 | 1.45 ilaa 1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11 ilaa 0.16 | |

| L80 | 0.15 ilaa 0.22 | ≤1.00 | 0.25 ilaa 1.00 | ≤0.020 | ≤0.010 | 12.0-14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26 ilaa 0.395 | 0.17 ilaa 0.37 | 0.40 ilaa 0.70 | ≤0.020 | ≤0.010 | 0.80 ilaa 1.10 | ≤0.20 | ≤0.20 | 0.15 ilaa 0.25 | ≤0.08 | |

Guryaha Makaanikada

| Darajo | Nooca | Wadarta dhererka culeyska saaran (%) | Xoog wax-soo-saar (min) | Awood wax-soo-saar (ugu badnaan) | Xoog xamaasada min Mpa | Hardness Max (HRC) | Hardness Max(HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | Dhammaan | 0.65 | 862 | 1034 | 931 | - | - |

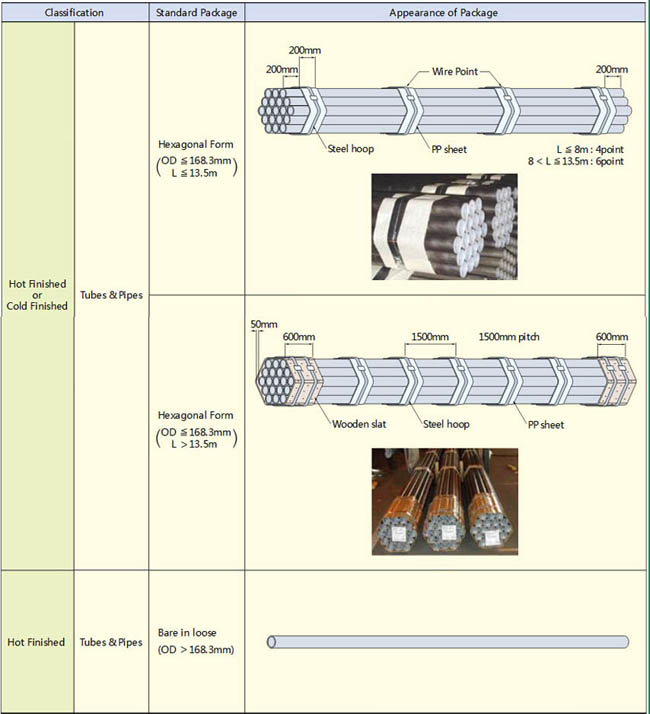

Keli leh bac xumbo ah ka dibna kiis alwaax ah (shahaadada fumigation).Kiis kasta si cad ayaa loogu calaamadeeyay:

1. Magaca & calaamada aqoonsiga saaraha-HuaDong Brand

2. Nambarka Dufcada

3. Taariikhda soo saaraha

4. Qalabka

5. kululaynta badbaadada & heerkulka codsiga