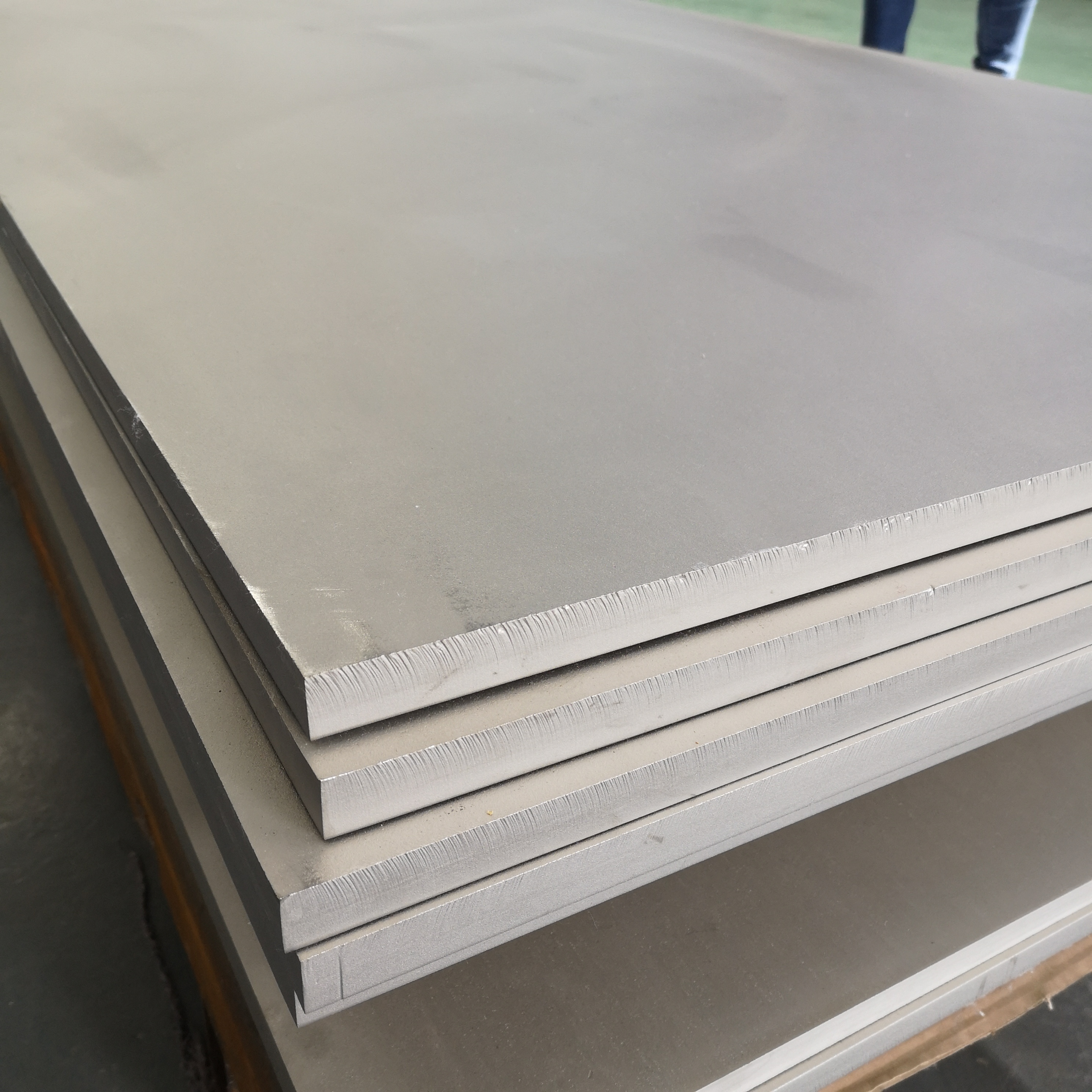

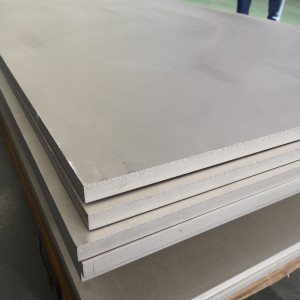

Titanium Sheet / saxan

Fasallada Guud

Titanium Fasalka 1waa sheyga titanium xoog yar oo aan alloyed, oo ka kooban ogsijiin yar oo awood qaab sare leh;darajadan titanium-ka waxa loo isticmaalaa xayndaabyada hawada, kulaylka lays dhaafsado iyo unugyada nadiifinta.

Titanium Fasalka 2waa wax soo saarka titanium xoog dhexdhexaad ah oo aan daahin.Darajada titanium-ka waxaa loo isticmaalaa xirmooyinka hawada, matoorada diyaaradaha iyo qaybaha badda;kartida alxanka wanaagsan iyo iska caabinta daxalka ayaa ah sifooyinka lagu garto.

Titanium Fasalka 3waa mid aan alloyed, xoog sare, alaabta titanium oo bixisa iska caabin daxalka wanaagsan iyo awoodda alxanka wanaagsan.Darajada titanium-ka waxa ugu horrayn loo adeegsadaa qaabka hawada iyo qaybaha mishiinnada diyaaradaha.

Titanium Fasalka 4waa xoogga ugu sarreeya ee saafiga ah alaabta titanium aan daawaynta lahayn.Darajada titanium-kan waxa si gaar ah loogu isticmaalaa qaabka hawada, qaybaha mishiinnada diyaaradaha, badda, qalliinka qalliinka, tuubooyinka hawo-qaadista.Awood qaab wanaagsan iyo iska caabbinta daxalka ayaa ah astaanteeda.

Titanium Fasalka 5 (6AL-4V)waa alaab titanium alloyed ka kooban 6% Aluminium iyo 4% Vanadium;waa badeecad xoog dhexdhexaad ah.Darajada titanium-ka waxaa inta badan loo isticmaalaa qalabka hawada iyo qaybaha matoorada marawaxadaha;iyo in loogu isticmaalo beer-qabashada qalliinka.Macluumaadka Farsamada Titanium 6AL-4V ELI waa alaab titanium alloyed ka kooban 6% Aluminium iyo 4% Vanadium, ELI (Extra Low Interstitial).

6AL-2Sn-4Zr-2Mo (6-2-4-2)waa alaab titanium alloyed ka kooban 6% Aluminium, 2% Tin, 4% Zirconium, 2% Molybdenum.

6AL-6V-2Sn (6-6-2)waa alaab titanium alloyed ka kooban 6% Aluminium, 6% Vanadium, 2% Tin.

5AL-2.5Sn & ELI (5-2.5)waa alaab titanium alloyed ka kooban 5% Aluminium iyo 2.5% Tin.Sidoo kale ELI (Extra Low Interstitial).

8AL-1V-1 Bisha (8-1-1)waa alaab titanium alloyed ka kooban 8% aluminium, 1% molybdenum iyo 1% Vanadium.

15V-3Cr-4AL-3Sn (15-3-4-3)waa alaab titanium alloyed ka kooban 15% Vanadium, 3% Chromium, 4% Aluminium, 3% Tin.

| Darajo | Xaalada | Tilmaamid | ||

| Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 | Kulul Duub (R) Qabow duuban Daaweynta Xalka (ST) | Dhumucda (mm) | Ballaca (mm) | Dhererka (mm) |

| 0.3 ilaa 60 | ≥400 | ≤ 6000 | ||

| Xaashida Titanium | |||

| Dhumucda | Darajooyinka | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Fiiro gaar ah: Cabiryo dheeri ah ayaa la heli karaa, ma aha dhammaan cabbirrada la muujiyay in laga heli karo kaydka.Fadlan nala soo xidhiidh si aad u hubiso helitaanka

| AMS:AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1E:EN 10204.3, EN 1-204:2005 3.1 NACE:NACE MR0175 ASME:ASME SB265 |

| Darajo | Tilmaamaha AMS/MIL | Noocyada ASTM |

| Fasalka 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 | ASTM B265 Gr1 xaashida/saaradda ASTM B337 Gr1 tuubo ASTM B338 Gr1 tube ASTM B348 Gr1 ASTM F67 Gr1 Qalliinka Maqaarka |

| Fasalka 2 | Fasalka 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 AMS 4941 AMS 4942 AMS 4951 silig alxanka | ASTM B265 Gr2 xaashida/saancadda ASTM B337 Gr2 tuubo ASTM B338 Gr2 tube ASTM B348 Gr2 ASTM F67 Gr2 Qalliinka Maqaarka |

| Fasalka 3 | AMS-T-9046B CP2 AMS 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 xaashida / saxan ASTM B337 Gr3 tuubo ASTM B338 Gr3 tube ASTM B348 Gr3 bar ASTM F67 Gr3 Qalliinka Maqaarka |

| Fasalka 4 | AMS-T-9046B CP1 AMS-T-9047A CP70 AMS4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 | ASTM B265 Gr4 xaashida / saxan Tuubbada ASTM B337 Gr4 ASTM B338 Gr4 tube ASTM B348 Gr4 ASTM F67 Gr4 Qalitaanka Qalliinka |

| Fasalka 7 | ASTM B265 Gr7 xaashida/saaradda ASTM B337 Gr7 tuubo ASTM B338 Gr7 tube ASTM B348 Gr7 |

| Darajo | Noocyada US | Noocyada ASTM |

| Fasalka 5 6 Al-4V | AMS 4907 ELI AMS 4911 AMS 4928 AMS 4930 ELI AMS 4931 ELI Duplex ann AMS 4963 AMS 4965 AMS 4967 AMS 4985 AMS 4991 AMS 6931 AMS 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Nooca 3 Comp C MIL-T-9046H Nooca 3 Comp D AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 xaashi/saanrad ASTM B348 Gr5 ASTM F136 Gr5 Fasalka Maqaarka |

| Fasalka 9 3 Al-2.5V | AMS 4943 AMS 4944 AMS 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 xaashida/saanadda ASTM B348 Gr6 |

| Fasalka 23 6 Al-4V ELI | AMS4907 AMS 4930 AMS 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 xaashi / saxan / xadhig ASTM B348 Gr23 bar/billet ASTM F136 Gr23 Implant Gra |

Halabuurka kiimikada

| Darajo | Halabuurka kiimikada, boqolkiiba miisaanka (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Qaybaha Kale Max.mid walba | Qaybaha Kale Max.wadarta guud | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12~0.25 | - | 0.12~0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12~0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04~0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | - | - | - | - | 0.1 | 0.1 |

Tilmaamaha jirka

| Darajo | Tilmaamaha jirka | ||||||

| Xoog xajin Min | Xoog soo saar (0.2%, la dhimay) | Kordhinta 50mm Ugu yaraan (%) | |||||

| ksi | MPa | Min | Max | ||||

| ksi | MPa | ksi | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | - | - | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | - | - | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | - | - | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | - | - | 10 |

Dulqaadka (mm)

| Dhumucda | Dulqaad ballaaran | ||

| 400 ~ 1000 | 1000-2000 | >2000 | |

| 5.0-6.0 | ±0.35 | ±0.40 | ±0.60 |

| 6.0 ilaa 8.0 | ±0.40 | ±0.60 | ±0.80 |

| 8.0-10.0 | ±0.50 | ±0.60 | ±0.80 |

| 10.0-15.0 | ±0.70 | ±0.80 | ±1.00 |

| 15.0-20.0 | ±0.70 | ±0.90 | ±1.10 |

| 20.0-30.0 | ±0.90 | ±1.00 | ±1.20 |

| 30.0 ~ 40.0 | ±1.10 | ±1.20 | ±1.50 |

| 40.0-50.0 | ±1.20 | ±1.50 | ± 2.00 |

| 50.0 ~ 60.0 | ± 1.60 | ± 2.00 | ± 2.50 |