Qaybaha halbeegyada Titanium

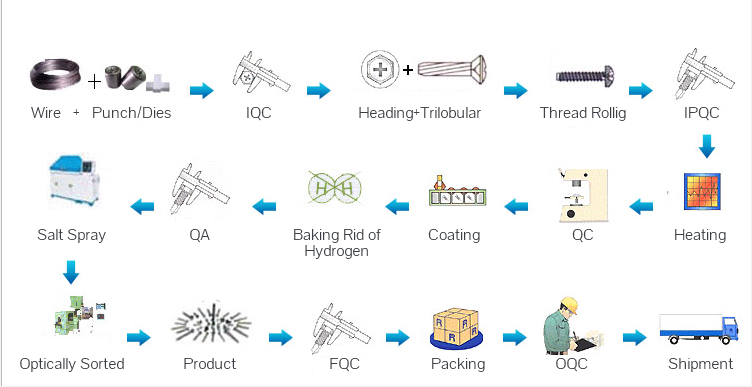

Wax soo saarka DIN, ANSI / AMSE, ISO, JIS iyo heerarka kale iyo kuwa aan caadiga ahayn ee titanium-xoogga sare.Caadi ahaan waxaa ka mid ah boolal, boolal, nuts, dhaqdhaqaajiyaal, giraanta haynta, iyo qaybo gaar ah oo kala duwan.Marka hore, waxaanu samayn doonaa daaweynta kulaylka, tijaabinta ka kooban kiimikada, tijaabinta sifooyinka farsamada ee baararka titanium, taarikada titanium iyo qalabka kale ee aasaasiga ah.Ka dib habka toosinta, sinnaanta iyo nadiifinta, googooyaa cabbirka ku habboon.Ka dibna u gudub leexashada, shaabada kulul, furka isku-buufinta, daawaynta kulaylka, suufka, nadiifinta, kormeerka, iyo habraacyo taxane ah, ugu dambayntii si aad u soo saartid xirmooyinka titanium tayo sare leh.Waxaan haynaa qalabka wax soo saarka ee horumarsan kaas oo hubiyay alaabtayada si aan u gaarno sida ugu fiican ee isku xirka wax soo saarka kasta.

Shirkaddayadu waxay leedahay alaab badan oo titanium-ka xirmooyinka, kaas oo ku qancin kara dalabaadka yar ee caalamiga ah iyo kuwa macaamiisha leh shuruudaha gaarsiinta degdegga ah.Isla mar ahaantaana, waxaan sidoo kale ku siinnaa alaab aan caadi ahayn sida ku cad sawirada ay bixiyaan macaamiisha.

Codsiga

Batroolka, biraha, kiimikaadka, elektiroonigga, dawooyinka, injineernimada badda, qaybaha baabuurta, qaybaha mootooyinka, qaybaha baaskiilka, qalabka doonyaha, agabka badbaadada dibadda, alaabta ciyaaraha iyo qaybaha kale.

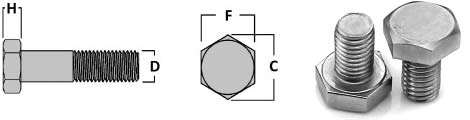

Titanium bool

| Alaabta | Titanium iyo Titanium alloy bolt |

| Cabbirka | Dhexroor: M1.6-M30, Dhererka: 10mm-300mm (0.39″-11.8″) |

| Qalab | Gr.1, Gr.2, Gr.5, Gr.7 iwm |

| Heerka | DIN912, DIN6912, DIN933, DIN931 iwm |

Titanium hex nuts

| Alaabta | Titanium iyo Titanium alloy lowska |

| Cabbirka | M8-M 80 x 6 |

| Qalab | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, iwm |

| Heerka | DIN, ISO, JIS, iwm. |

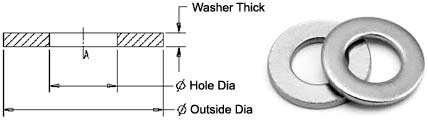

Titanium dhaqe

| Alaabta | Titanium iyo Titanium Alloy washer |

| Cabbirka | OD: 5mm-200mm (0.20″-7.87″), Aqoonsiga: 1mm-100mm (0.04″-3.94″), Dhumucdiisuna: 0.1mm-30mm (0.004″-1.18″) |

| Qalab | Gr.2, Gr.5 iwm |

| Heerka | DIN125 iwm |

Titanium screw

| Alaabta | Titanium iyo Titanium Alloy screw |

| Cabbirka | M1 ilaa M42, Dhererka: 10mm-300mm (0.39″-11.8″) |

| Qalab | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 iwm |

| Heerka | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, iwm. |

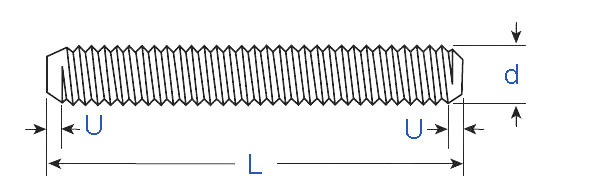

Tiitaaniyam dunta ka samaysan

| Alaabta | Titanium iyo Titanium aluminium ah oo xadhig leh |

| Cabbirka | Dhexroor: M1.6-M30, Dhererka: 10mm-300mm (0.39″-11.8″) |

| Qalab | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 iwm |

| Heerka | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS iwm. |

Titanium Hex Bolts Cabbirrada

| Dhexroor Hex Bolt Culus | D | F | C | H | |||||

| Dhexroorka Jirka | Balaadhka Guryaha Dhan | Balaadhka geesaha geesaha | Dhererka | ||||||

| Max | Aasaaska | Max | Min | Max | Min | Aasaaska | Max | Min | |

| 1/2 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 11/32 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0.876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Cabbirrada Hex Nuts

| ISO Titanium Hex Nut NB | Geesaha Dhan | Dhumucda MAX | Dhumucda MIN | MAX Guud ahaan Guryaha | MIN Guud ahaan Guryaha |

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x 6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Tiitanium Flat Washer Cabbirrada

| Ti Alloy Bolt Size | USS | SAE | ||||

| OD (gud.) | Aqoonsiga (gud.) | Dhumucda | OD (gud.) | Aqoonsiga (gud.) | Dhumucda | |

| 1/8 (#6) | - | - | - | 0.375 | 0.156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0.438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0.562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0.875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

| 3/8 | 1.000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0.562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0.938 | .136/192 | 1.750 | 0.938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/192 | 2.500 | 1.375 | .136/192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249/.327 | - | - | - |

Socket Head Cap Screw Cabbirrada

| Ti Alloy Screw Nom.Xajmiga Dulsaarka Xajmiga | Jirka | Madaxa | Madaxa | Chamfer | Hexagon | Spline | Furaha | Kala-guurka | |||

| Max | Min | Max | Min | Max | Min | Max | Nom. | Nom. | Min | Max | |

| M1.6 × 0.35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0.80 | 2.0 |

| M2 × 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2.5 × 0.45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0.5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1.50 | 3.6 |

| M4 × 0.7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 × 0.8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0.50 | 4.0 | 4.648 | 2.50 | 5.7 |

| M6 × 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 × 1.25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 × 1.5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1.75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2.5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3.5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | … | 15.00 | 33.4 |

| M36 × 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | … | 18.00 | 39.4 |

| M42 × 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | … | 21.00 | 45.6 |

| M48 × 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | … | 24.00 | |

Tiitaaniyam dunta ka samaysan

| ANSI /ASMEB 18.31.2 Xarig-Unit: inch | ||||

| d | garoonka | |||

| UNC | UNF | 8UN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0.3125 | 18 | 24 | / |

| 3/8 | 0.375 | 18 | 24 | / |

| 7/16 | 0.4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0.5625 | 12 | 18 | / |

| 5/8 | 0.625 | 11 | 18 | / |

| 3/4 | 0.75 | 10 | 16 | / |

| 7/8 | 0.875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Cutub: inji | ||||

| d | garoonka | |||

| UNC | UNF | 8UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2<L≤2-1/2 | 2-1/2<L≤4 | 4L≤8 | 8 L≤16 | 16 L |

| Dulqaadka dhererka istaarka ee la adkeeyay | ±0.04 | ±0.08 | ±0.10 | ±0.12 | ±0.18 |

| Heerka | Sharaxaada | Heerka | Sharaxaada |

| DIN 84 | boolal madaxa farmaajo Slotted | DIN 439 | Jam nuts |

| DIN 125 | Mashiinnada fidsan | DIN 963 | Nalalka madaxa fidsan ee go'ay |

| DIN 127 | Qufulka qufulka guga | DIN 965 | Phillips mashiinnada madaxa ee fidsan |

| DIN 912 | furka madaxa godka hex | DIN 985 | Quful nuts (oo leh galinta aan biraha ahayn) |

| DIN913/DIN 914/DIN915/DIN916 | Dhig boolal | DIN 1665/DIN 6921 | Boolal hex ah oo leh flange |

| DIN 931 | Xirmooyinka koofiyadaha madaxa ee hex ( dun qayb ah) | DIN 6912/DIN 7984 | Xirmooyinka koofiyada madaxa khafiifka ah ee hexagon |

| DIN 933 | Xirmooyinka koofiyadaha madaxa hex (dulan buuxa) | DIN 7991 | Koofiyadaha koofiyadaha madaxa oo siman |

| DIN 934 | Hex nuts | DIN 9021 | Makiinada fidsan |

Qalab u dhigma oo loogu talagalay xirayaasha Titanium

| HEERKA | SHAQADA NR. | UNS |

| Titanium Fasalka 2 | 3.7035 | R50400 |

| Titanium Fasalka 5 | 3.7165 | R56400 |

Astaamaha Farsamada ee Xidhiyaasha Titanium

| Darajo | Xoogga Jilitaanka (daqiiqo) | Xoogga Wax-soo-saarka 0.2% Deminta | Kordhinta 2 inch ama 50mm % (daqadda) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20 - 45 | 138 - 310 | 24 |

| Gr.2 | 50 | 345 | 40 - 65 | 275 - 450 | 20 |

| Gr.3 | 65 | 450 | 55 - 80 | 380 - 550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| Curiyaha | Cufnaanta | Meesha dhalaalaysa | Xoogga Jilicsan | Xoogga Wax-soo-saarka (0.2% ka-baxsan) | Dheeraynta |

| Titanium Gr.2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900, MPa – 275 | 20% |

| Titanium Gr.5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14% |

Qalab Kiimikada ah ee Xidhayaasha Titanium

| Darajo | Fe% | C% | N% | H% | O% | Al% | V% | Mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | - | - | - | - | - | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | - | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | - | - | - | - | - | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0.015 | 0.40 | - | - | - | - | - | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0.015 | 0.02 | 5.5 - 6.75 | 3.5 - 4.5 | - | - | - | BAL |

| Gr7 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | 0.12 - 0.25 | BAL. |

| Gr9 | 0.25 | 0.08 | 0.03 | 0.015 | 0.15 | 2.5 - 3.3 | 2.0 - 3.0 | - | - | - | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | 0.2 - 0.4 | 0.6 - 0.9 | - | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0.015 | 0.13 | 5.5 - 6.75 | - | - | - | - | B |