Paip aloi nikel

| bahan | Monel/Inconel/Hastelloy/Keluli Dupleks/Keluli PH/Alloy Nikel |

| bentuk | Bulat, Penempaan, Cincin, Gegelung, Bebibir, Cakera, Kerajang, Sfera, Reben, Petak, Bar, Paip, Lembaran |

| Gred | N02200, N02201, N04400, N06600, N06601, N06625, N06690, N08810, N08825, N08020, N11,0280, N180280 665、N06022、N06030、GH3030、GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel 1NS311430 NS3 NS112,Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4 Monel K500,N05500 |

| Spesifikasi | Lain-lain: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 dll |

| Aloi :aloi 625, Aloi 20/28/31 | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001, Hastelloy B-2 / UNS N10665 / DIN W. Nr.2.4617, Hastelloy C, Hastelloy C-4 / UNS N06455 / DIN W. Nr.2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr.2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr.2.4819,Hastelloy X / UNS N06002 / DIN W. Nr.2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Siri Inconel:Inconel 600/601/602CA/617/625/690/713/718/738/X-750, Tukang Kayu 20; | |

| Inconel 718 / UNS N07718 /N04400/N06600/N08825/DIN W. No.2.4668,Inconel 601 / UNS N06601 / DIN W. Nr.2.4851, Inconel 625 / UNS N06625 / DIN W. Nr.2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669,Inconel 600 / UNS N06600 / DIN W. Nr.2.4816 | |

| Incoloy:Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel:Monel 400/K500/R405 | |

| Nitronik: Nitronik 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Kawat: 0.01-10mm Jalur: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Panjang 2000-5000mm Paip: φ6-273mm;δ1-30mm;Panjang 1000-8000mm Helaian: δ 0.8-36mm;Lebar 650-2000mm;Panjang 800-4500mm | |

| produk Ciri-ciri | 1. Mengikut proses penyediaan boleh dibahagikan kepada superaloi ubah bentuk, aloi super tuangan dan aloi super metalurgi serbuk. 2. Mengikut mod pengukuhan, terdapat jenis pengukuhan penyelesaian pepejal, pemendakan jenis pengukuhan, jenis pengukuhan penyebaran oksida dan jenis pengukuhan gentian, dsb. |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS dll |

| Pemeriksaan | ISO, SGS, BV, dan sebagainya. |

| Permohonan | Komponen suhu tinggi seperti bilah turbin, baling pemandu, cakera turbin, tekanan tinggi cakera pemampat, pembuatan mesin dan kebuk pembakaran yang digunakan dalam pembuatan turbin gas penerbangan, laut dan industri |

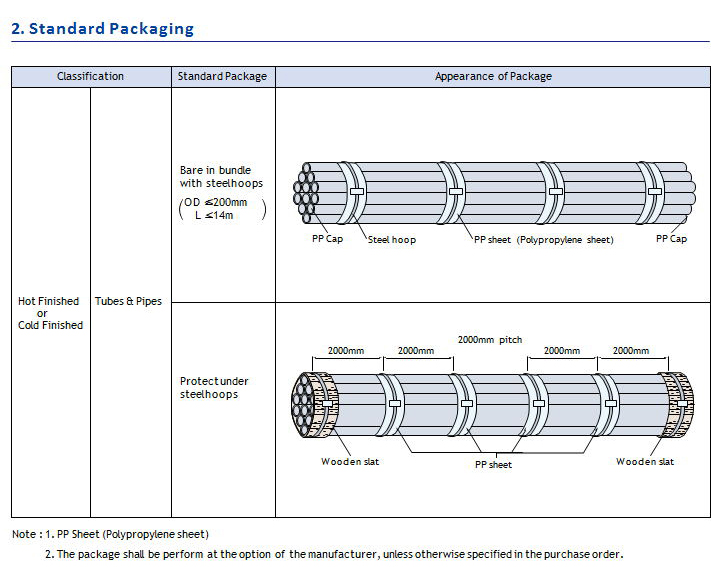

| Pembungkusan | 1. kes dibungkus dalam kes kayu 2. pembungkusan kertas 3. pembungkusan plastik 4. pembungkusan buih Pembungkusan mengikut keperluan pelanggan atau produk |

| Penghantaran | 7-25days atau mengikut produk |

| Bayaran | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Mengikut pembayaran keperluan pelanggan untuk pesanan luar talian. |

| SAIZ STOK | |||||||||||||

| SAIZ | NIKEL | ALOI | ALOI | ALOI | ALOI | ALOI | ALOI | ALOI | ALOI | ALOI | ALOI | SAIZ | |

| 1/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 1.65mm | |

| 0.010 | X | X | .25mm | ||||||||||

| 0.020 | X | .51mm | |||||||||||

| 1/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 3.18mm | |

| 0.010 | X | 0.25 | |||||||||||

| 0.012 | X | 3.05mm | |||||||||||

| 0.016 | X | .31mm | |||||||||||

| 0.020 | X | X | X | .51mm | |||||||||

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | .89mm | ||||||||

| 3/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 4.76mm | |

| 0.010 | X | .25mm | |||||||||||

| 0.016 | X | X | .31mm | ||||||||||

| 0.020 | X | .51mm | |||||||||||

| 0.028 | X | X | X | .71mm | |||||||||

| 0.035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | 1.24mm | |||||||||

| 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 6.35mm | |

| 0.016 | X | .31mm | |||||||||||

| 0.020 | X | X | X | .51mm | |||||||||

| 0.028 | X | X | X | X | X | .71mm | |||||||

| 0.035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | X | 1.24mm | ||||

| 0.065 | X | X | X | X | X | X | X | 1.65mm | |||||

| 0.083 | X | 2.11mm | |||||||||||

| 5/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 7.94mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1.24mm | |||||||||||

| 0.065 | X | X | X | 1.65mm | |||||||||

| 3/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 9.53mm | |

| 0.020 | X | .51mm | |||||||||||

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | X | 1.65mm | |||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 7/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 11.1mm | |

| 0.035 | X | .89mm | |||||||||||

| 0.065 | X | 1.65mm | |||||||||||

| 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 12.7mm | |

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | X | .89mm | |||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.058 | X | X | 1.47mm | ||||||||||

| 0.065 | X | X | X | X | X | X | X | X | 1.65mm | ||||

| 0.083 | X | X | X | 2.11mm | |||||||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | 2.77mm | |||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 9/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 14.3mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | X | 1.24mm | ||||||||

| 0.065 | X | X | X | 1.65mm | |||||||||

| 0.083 | X | 2.11mm | |||||||||||

| 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 15.9mm | |

| 0.035 | X | X | X | X | X | .89mm | |||||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | 1.65mm | ||||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 3/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 19.1mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | X | X | X | X | .89mm | |||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | X | X | X | X | 1.65mm | ||

| 0.083 | X | X | X | X | X | X | X | 2.11mm | |||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | X | X | X | 2.77mm | ||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 22.2mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | 1.24mm | |||||||||

| 0.065 | X | X | X | X | 1.65mm | ||||||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 1″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 25.4mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | X | X | 1.65mm | ||||

| 0.083 | X | X | X | X | X | X | X | 2.11mm | |||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | X | X | X | 2.77mm | ||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.134 | X | X | |||||||||||

| 1 1/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 28.6mm | |

| 0.049 | X | ||||||||||||

| 1 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 31.8mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1.24mm | |||||||||||

| 0.065 | X | X | X | X | X | X | 1.65mm | ||||||

| 0.083 | X | X | X | X | 2.11mm | ||||||||

| 0.095 | X | 2.41mm | |||||||||||

| 0.109 | X | 2.77mm | |||||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 38.1mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | X | 1.24mm | |||||||||

| 0.065 | X | X | X | X | X | X | 1.65mm | ||||||

| 0.083 | X | X | X | 2.11mm | |||||||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | X | X | 2.77mm | |||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 41.3mm | |

| 0.065 | X | 1.65mm | |||||||||||

| 0.083 | X | 2.11mm | |||||||||||

| 1 3/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 44.5mm | |

| 0.065 | X | X | X | 1.65mm | |||||||||

| 1 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 47.6mm | |

| 0.083 | X | 2.11mm | |||||||||||

| 2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 50.8mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | 1.24mm | ||||||||||

| 0.065 | X | X | X | X | X | 1.65mm | |||||||

| 0.083 | X | X | X | X | 2.11mm | ||||||||

| 0.095 | X | 2.41mm | |||||||||||

| 0.109 | X | X | 2.77mm | ||||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 2 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 57.2mm | |

| 0.035 | X | .89mm | |||||||||||

| 0.049 | X | 1.24mm | |||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 2 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 63.5mm | |

| 0.065 | X | X | X | X | 1.65mm | ||||||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 0.109 | X | 2.77mm | |||||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 3″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 76.2mm | |

| 0.065 | X | X | X | X | 1.65mm | ||||||||

| 0.083 | X | X | X | 2.11mm | |||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.250 | X | 6.35 | |||||||||||

| 3 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 82.6mm | |

| 0.125 | X | 3.18 | |||||||||||

| 3 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 88.9mm | |

| 0.375 | 9.53mm | ||||||||||||

| Standard | – ASTM A270,ASTM A249,ASTM A511,ASTM A778 ,ASTM A312,ASTM A358,ASTM A409,ASTM A213,ASTM A790,ASTM A268,ASTM A269,ASTM A554,ASTM B333,ASTM767,ASTM77 B675, ASTM B676, ASTM B690, ASTM A928, ASME B36.19, ASME B36.10– EN10216-5, EN10217-7, DIN 17456, DIN 17458 – JIS G3463,JIS G3119,JIS G3446,JIS G3218,JIS G3258,JIS G3448,JIS H4631– DEP 31,DEP 40,DEP 20,DEP 32,DNV-OS-F101 |

| Julat Saiz | OD:NPS 1/8 -80, BN 6 – 2000, 10.3 – 2030 , Alao kapilariWT:Sch5s-Sch160s, SchXXH, STD,XS,XXSPanjang:Penyesuaian |

| Gred | S32750, 00Cr25Ni7Mo4N, 022Cr25Ni7Mo4N, 1.441, 1.4307/1.4301/304L/3, S30408/S30403, 0Cr18Ni9DQ, 1.4948/3048 4948, 06Cr23Ni13, S30908, SUS309S, SUS310S, 1.4845, S31008, S31008S, 06Cr25Ni20, 0Cr25Ni20, 1.4401/1.4404/316/31, S31635, SUS316Ti, 1.4571, 1.4571/316Ti, S31703, 022Cr19Ni13Mo3, 00Cr17Ni12Mo2, S31703, S31703, S31703, SUS. 410S, 1.4, 06Cr13, S11306, 0Cr13, S42000, SUS420J1, 1.4021, SUS420J2, 1.4028, S43020, 430F, SUS430F, 1.4104, , 301, 302, 303, 305, 309, 310, 316, 317, 321, 347, 403, 41 62, 403, 41 62,45 07, 304/304L, 304DQ . 0, 630, XM19, C4, S30815 , S31254, 174PH, F51, F60, F53, S32760, 253MA, HC2000, 800H, 926, GH2132, GH4169, GH3030, GH3039, GH4151, N0434, NCMo, N0434 08810 |

| ASTM B111 / ASME SB111 | Spesifikasi Standard untuk Tiub Pemeluwap Lancar Kuprum dan Aloi Kuprum dan Stok Ferrule | |

| ASTM B161 / ASME SB161 | Spesifikasi Standard untuk Paip Nikel Lancar dan Tiub | |

| ASTM B163 / ASME SB163 | Spesifikasi Standard untuk Kondenser Aloi Nikel dan Nikel Lancar dan Tiub Penukar Haba | |

| ASTM B165 / ASME SB165 | Spesifikasi Standard untuk Aloi Nikel-Tembaga (UNS N04400)* Paip dan Tiub Lancar | |

| ASTM B167 / ASME SB167 | Spesifikasi Standard untuk Aloi Nikel-Kromium-Besi, Nikel-Kromium-Kobalt-Molibdenum Aloi (UNS N06617), dan Nikel-Besi-Kromium-Tungsten Aloi (UNS N06674) Paip Lancar dan Tiub | |

| ASTM B395 / ASME SB395 | Spesifikasi Standard untuk U-Bend Seamless Copper and Copper Alloy Heat Exchanger and Condenser Tiub | |

| ASTM B407 | Spesifikasi Standard untuk Paip dan Tiub Lancar Aloi Nikel-Besi-Kromium | |

| ASTM B423 / ASME SB423 | Spesifikasi Standard untuk Aloi Nikel-Kromium-Molibdenum-Kolumbium (UNS N06625 dan UNS N06852) dan Aloi Nikel-Kromium-Molibdenum-Silikon (UNS N06219) Paip dan Tiub | |

| ASTM B444 / ASME SB444 | Spesifikasi Standard untuk Aloi Nikel-Kromium-Molibdenum-Kolumbium (UNS N06625 dan UNS N06852) dan Aloi Nikel-Kromium-Molibdenum-Silikon (UNS N06219) Paip dan Tiub | |

| ASTM B622 / ASME SB622 | Spesifikasi Standard untuk Paip dan Tiub Aloi Nikel dan Nikel-Kobalt Lancar | |

| ASTM B668 / ASME SB668 | Spesifikasi Standard untuk UNS N08028 dan N08029 Paip dan Tiub Lancar | |

| ASTM B677 / ASME SB677 | Spesifikasi Standard untuk UNS N08925, UNS N08354 dan UNS N08926 Paip dan Tiub Lancar | |

| ASME SB690 / ASME SB690 | Spesifikasi Standard untuk Aloi Besi-Nikel-Kromium-Molibdenum (UNS N08366 dan UNS N08367) Paip dan Tiub Lancar | |

| ASTM B705 / ASME SB705 | Spesifikasi Standard untuk Paip Dikimpal Nikel-Alloy (UNS N06625, N06219 dan N08825) | |

| ASTM B729 / ASME SB729 | Spesifikasi Standard untuk paip dan Tiub aloi nikel UNS N08020, UNS N08026 dan UNS N08024 yang lancar | |

| ASTM B829 / ASME SB829 | Spesifikasi Standard untuk Keperluan Am untuk Paip dan Tiub Lancar Nikel dan Aloi Nikel |

Komposisi kimia:

| Gred | Komposisi kimia | ||||||||

| C | Si max | Mn maks | P | S | Ni | Cr | Mo | Ti | |

| 200 | 0.15 | 0.35 | 0.35 | 0.010 | 99 min | ||||

| 201 | 0.02 | 0.35 | 0.35 | 0.010 | 99 min | ||||

| 400 | 0.30 | 0.50 | 2.00 | 0.024 | 63 min | ||||

| 600 | 0.15 | 0.50 | 1.00 | 0.015 | 72 min | 14 – 17 | |||

| 601 | 0.10 | 0.50 | 1.00 | 0.015 | 58 – 63 | 21 – 25 | |||

| 625 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 58 min | 20 – 23 | 8 – 10 | 0.40 maks |

| 800 | 0.10 | 1.00 | 1.50 | 0.03 | 0.015 | 30 – 35 | 19 – 23 | 0.15 0.60 | |

| 800H | 0.05 0.10 | 1.00 | 1.50 | 0.015 | 30 – 35 | 19 – 23 | 0.15 0.60 | ||

| 825 | 0.05 | 0.50 | 1.00 | 0.03 | 38 – 46 | 19.5 23.5 | 2.5 3.5 | 0.6 1.2 | |

| 904L | 0.02 | 1.00 | 2.00 | 0.030 | 0.015 | 24 – 26 | 19 23 | 4 5 | |

Sifat Fizikal Aloi Nikel

| ALOI | KEPADATAN ALOI NICKEL | KEKONDUKSIAN TERMA | LINEAR TERMA , KOEF PENGEMBANGAN., (20-95 °C) | RINTANGAN ELEKTRIK , PADA 20°C |

| G/CM³ | W/MK | 10-6/K | ΜΩ-CM | |

| NI 200/201 | 8.89 | 70.20 | 13.3 | 9 |

| NI 205/205 LC | 8.89 | 75.00 | 13.3 | 8.9 |