Paip Keluli ASTM A335

| Nama Produk | Paip Keluli Aloi |

| bahan | Besi aloi |

| Panjang Paip | Panjang Rawak Tunggal dan Panjang Rawak berganda.SRL:3M-5.8M DRL:10-11.8M atau Panjang yang diminta pelanggan |

| Saiz | Saiz 1/4”ke 24”Diameter Luar 13.7 mm hingga 609.6 mm |

| ketebalan dinding | SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100 SCH120, SCH160, XS, XXS |

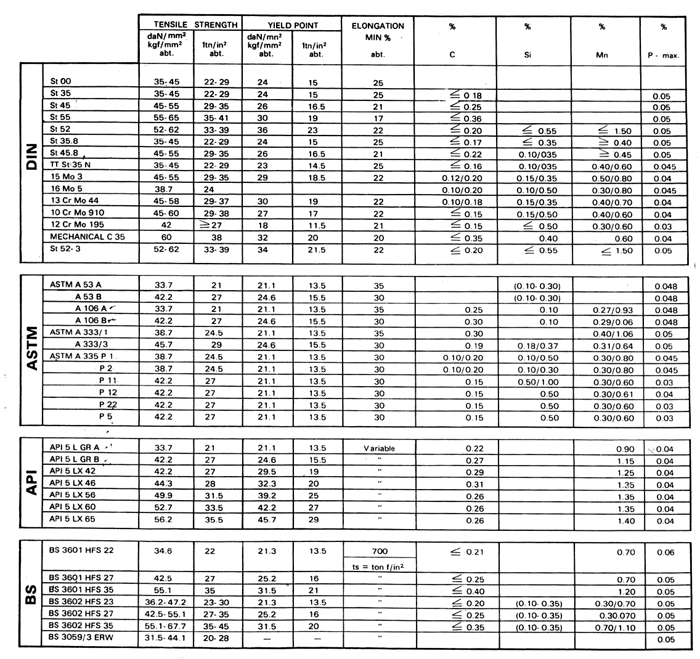

| Standard | ASTM A 335 Gred P1, P2, P5, P9, P9A, P11, P22.ASTM A213 T1B, T1, T2, T5, T9, T9A, T11, T12, T22.A199 T5, T9, T11, T22.BS 3604 Gred 621, 622, 625, 629-470, 629-590, 660, 762.DIN 17175 15 Mo 3, 13 Cr Mo 44, 10 Cr Mo 910, 14 Mo V 63, X 20 Cr MoBS 309 , 620-460, 622-490, 629-470, 629-590, 762. JISG3458/G3462/3467 dan DIN17175-79. |

| Aplikasi | 1.Paip cecair 2. Loji janakuasa 3. Paip struktur 4. Tiub Dandang tekanan tinggi dan rendah 5. Tiub keluli lancar untuk keretakan petroleum 6. Paip konduit 7. Perancah paip farmaseutikal dan pembinaan kapal dll |

| Sijil | ISO/PED/TUV/SGS/LR/BV |

| Pasaran Utama | Asia, Timur Tengah, Eropah, Amerika, Afrika, Australia, dll |

Komposisi kimia(%):

| Gred | Jawatan UNS | Komposisi, % | |||||||

| Karbon | Mangan | fosforus, | Sulfur | silikon | Chromium | Molibdenum | Lain-lain | ||

| maks | maks | ||||||||

| P1 | K11522 | 0.10–0.20 | 0.30–0.80 | 0.025 | 0.025 | 0.10–0.50 | — | 0.44–0.65 | — |

| P2 | K11547 | 0.10–0.20 | 0.30–0.61 | 0.025 | 0.025 | 0.10–0.30 | 0.50–0.81 | 0.44–0.65 | — |

| P5 | K41545 | 0.15 maks | 0.30–0.60 | 0.025 | 0.025 | 0.50 maks | 4.00–6.00 | 0.45–0.65 | — |

| P9 | S50400 | 0.15 maks | 0.30–0.60 | 0.025 | 0.025 | 0.25–1.00 | 8.00–10.00 | 0.90–1.10 | — |

| P11 | K11597 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50–1.00 | 1.00–1.50 | 0.44–0.65 | — |

| P12 | K11562 | 0.05–0.15 | 0.30–0.61 | 0.025 | 0.025 | 0.50 maks | 0.80–1.25 | 0.44–0.65 | — |

| P15 | K11578 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 1.15–1.65 | — | 0.44–0.65 | — |

| P21 | K31545 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50 maks | 2.65–3.35 | 0.80–1.06 | — |

| P22 | K21590 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50 maks | 1.90–2.60 | 0.87–1.13 | — |

| P23 | K41650 | 0.04–0.10 | 0.10–0.60 | 0.03 | 0.01 | 0.50 maks | 1.90–2.60 | 0.05–0.30 | V 0.20–0.30 |

| Cb 0.02–0.08 | |||||||||

| B 0.0005–0.006 | |||||||||

| N 0.030 maks | |||||||||

| Al 0.030 maks | |||||||||

| W 1.45–1.75 | |||||||||

| P91 | K91560 | 0.08–0.12 | 0.30–0.60 | 0.02 | 0.01 | 0.20–0.50 | 8.00–9.50 | 0.85–1.05 | V 0.18–0.25 |

| N 0.030–0.070 | |||||||||

| Ni 0.40 maks | |||||||||

| Al 0.04 maks | |||||||||

| Cb 0.06–0.10 | |||||||||

| P92 | K92460 | 0.07–0.13 | 0.30–0.60 | 0.02 | 0.01 | 0.50 maks | 8.50–9.50 | 0.30–0.60 | V 0.15–0.25 |

| N 0.03–0.07 | |||||||||

| Ni 0.40 maks | |||||||||

| Al 0.04 maks | |||||||||

| Cb 0.04–0.09 | |||||||||

| W 1.5–2.00 | |||||||||

| B 0.001–0.006 | |||||||||

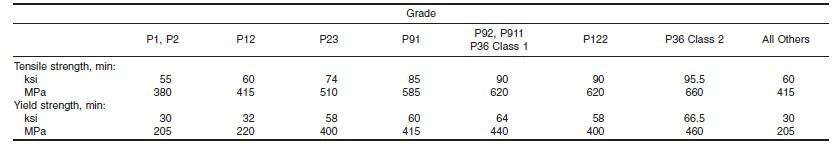

Sifat Mekanikal:

Salutan hitam, minyak/varnis, FBE, 2PE, 3PE, tergalvani dan lain-lain Butiran Pembungkusan: Pembungkusan dalam berkas atau untuk keperluan pelanggan