Titanium signa partes

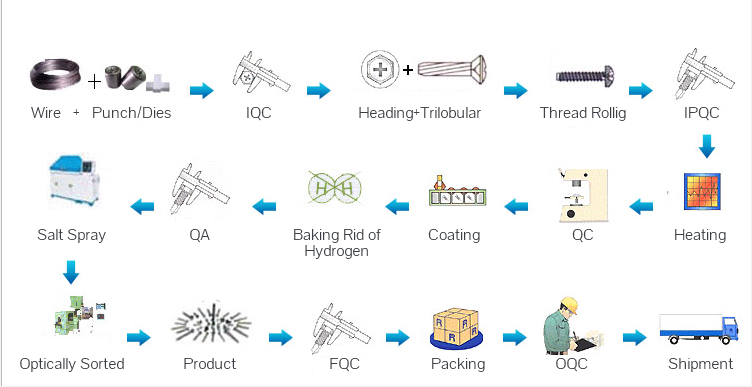

Productio DIN, ANSI/AMSE, ISO, JIS et aliis signis et non-vexillaribus maximis viribus titanii figentium.Solet includere seras, cochleas, nuces, washers, anulum retinens, et varias partes speciales informes.Primo faciemus tractationem caloris, compositionem chemicam probationem, proprietates mechanicas tentantes titanium vectes, laminas titanium et alias materias fundamentales.Post processum directio, aequandi et expolitio, convenienter inciditur in magnitudine.Et deinde ad conversionem, calcationem calidam, cochleae compressionem, curationem caloris, expolitio, purgatio, inspectio, et series procedendi, tandem ad producendum fastigium optimum titanium.Provectio instrumenti productionis habemus quae nostros fructus efficere curavimus ut optimus quisque nexus productionis efficiatur.

Societas nostra multum habet inventarium clavicularium titanium, quod potest implere parvam quantitatem ordinum globalis et clientium cum urgente traditione postulationem.Eodem tempore, etiam producta non-vexilla providemus secundum delineatas a clientibus.

Applicationem

Petroleum, metallurgia, chemica, electronica, pharmaceutica, machinae marinae, partes autocinetae, partes motorcycle, partes birotae, accessiones celetae, commeatus superstitiales velit, bona ludentes et alia arva.

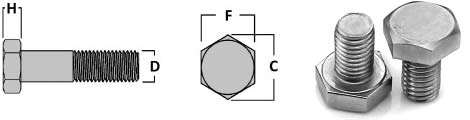

Titanium bolt

| Productum | Titanium et Titanium offensionis fulmen |

| Magnitudo | Diameter: M1.6-M30, Longitudo: 10mm-300mm (0.39″-11.8″) |

| Materia | Gr.1, Gr.2, Gr.5, Gr.7 etc |

| Standard | DIN912, DIN6912, DIN933, DIN931 etc |

Titanium hex nut

| Productum | Titanium et Titanium mixturae nucis |

| Magnitudo | M8-M 80 x 6 |

| Materia | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, etc |

| Standard | DIN, ISO, JIS, etc. |

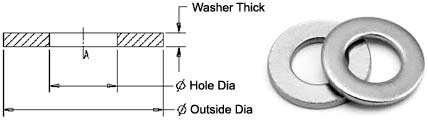

Titanium washer

| Productum | Titanium et Titanium stannum washer |

| Magnitudo | OD: 5mm-200mm (0.20″-7.87″), ID: 1mm-100mm (0.04″-3.94″), Crassitudo: 0.1mm-30mm (0.004″-1.18″) |

| Materia | Gr.2, Gr |

| Standard | DIN125 etc |

Titanium cochlea

| Productum | Titanium et Titanium mixturae cochleae |

| Magnitudo | M1 ad M42, Longitudo: 10mm-300mm (0.39″-11.8″) |

| Materia | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 etc |

| Standard | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, etc. |

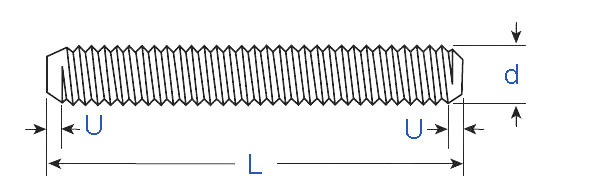

Titanium staminea bulla

| Productum | Titanium et Titanium mixtura staminea |

| Magnitudo | Diameter: M1.6-M30, Longitudo: 10mm-300mm (0.39″-11.8″) |

| Materia | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 etc |

| Standard | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS etc. |

Titanium Hex Bolts Dimensiones

| Gravis Hex Bolt Diameter | D | F | C | H | |||||

| Corpus Diameter | Latitudo per blandit | Latitudo per angulos | Altitudo | ||||||

| Max | Basic | Max | Min | Max | Min | Basic | Max | Min | |

| 1/2 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 11/32 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.759 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.602 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.093 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0.876 | 0.124 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Hex Nuces Dimensiones

| ISO Titanium Hex Nut NB | Per corners | MAX Crassitudo | MIN Crassitudo | MAX Per blandit | MIN Per blandit |

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x 6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Titanium Flat elementum Dimensiones

| Ti Alloy Bolt Size | USS | SAE | ||||

| OD (in.) | ID (in.) | Crassitudo | OD (in.) | ID (in.) | Crassitudo | |

| 1/8 (#6) | - | - | - | 0.375 | 0.149 | .036/.065 |

| 5/32 (#8); | - | - | - | 0.438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0.562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0.875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

| 3/8 | 1.000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0.562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0.938 | .136/.192 | 1.750 | 0.938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249/.327 | - | - | - |

Pentium Caput Cap Screw Dimensiones

| Ti Alloy Screw Nom.Magnitudo Thread Pix | Corpus | Caput | Caput | Chamfer | Hexagon | Spline | Clavis | Transitus | |||

| Max | Min | Max | Min | Max | Min | Max | Nom. | Nom. | Min | Max | |

| M1.6 0.35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0.80 | 2.0 |

| M2 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2.5 0.45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 0.5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1.50 | 3.6 |

| M4 0.7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 0.8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0.50 | 4.0 | 4.648 | 2.50 | 5.7 |

| M6 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 1.25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 1.5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | ... | 5.00 | 11.2 |

| M12 1.75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | ... | 6.00 | 14.2 |

| M14 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | ... | 7.00 | 16.2 |

| M16 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | ... | 8.00 | 18.2 |

| M20 2.5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | ... | 10.00 | 22.4 |

| M24 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | ... | 12.00 | 26.4 |

| M30 3.5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | ... | 15.00 | 33.4 |

| M36 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | ... | 18.00 | 39.4 |

| M42 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | ... | 21.00 | 45.6 |

| M48 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | ... | 24.00 | |

Titanium staminea bulla

| ANSI /ASMEB 18.31.2 Threaded Rods-Unit:inch | ||||

| d | picis | |||

| UNC | UNF | 8UN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0.3125 | 18 | 24 | / |

| 3/8 | 0.375 | 18 | 24 | / |

| 7/16 | 0.4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0.5625 | 12 | 18 | / |

| 5/8 | 0.625 | 11 | 18 | / |

| 3/4 | 0.75 | 10 | 16 | / |

| 7/8 | 0.875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Unitas: inch | ||||

| d | picis | |||

| UNC | UNF | 8UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2<L≤2-1/2 | 2-1/2<L≤4 | 4<L≤8 | 8<L≤16 | 16<L |

| Longitudo claui patientiae affixa | ±0.04 | ±0.08 | ±0.10 | ±0.12 | ±0.18 |

| Standard | Descriptio | Standard | Descriptio |

| DIN 84 | Slotted caseus caput ANISOCYCLUM | DIN 439 | Jam nuces |

| DIN 125 | plana washers | DIN 963 | Slotted countersunk plana caput ANISOCYCLUM |

| DIN 127 | Ver cincinno washers | DIN 965 | Phillips machina plana caput ANISOCYCLUM |

| DIN 912 | Hex ostium tabernaculi cap cochleis | DIN 985 | Cincinno nuces (cum non-metallicis inserta) |

| DIN913/DIN 914/DIN915/DIN916 | Set ANISOCYCLUM | DIN 1665/DIN 6921 | Hex fulmina cum LABIUM |

| DIN 931 | Hex caput cap cochleis (pars filum) | DIN 6912/DIN 7984 | Hexagon nervum tenue caput ANISOCYCLUM |

| DIN 933 | Hex caput cap ANISOCYCLUM (plena stamina) | DIN 7991 | Plana caput countersunk nervum cap cochleis |

| DIN 934 | Hex nuces | DIN 9021 | plana washer |

Material Equivalent Grades For Titanium Fasteners

| VEXILLUM | WERKSTOFF NR. | UNS |

| Titanium Grade2 | 3.7035 | R50400 |

| Titanium Grade5 | 3.7165 | R56400 |

Mechanica Characteres Titanium Fasteners

| Gradus | Distrahens fortitudo (min) | Fortitudo 0.2% cede cinguli | Prolongatio in 2 inch vel 50mm% (min) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20 - 45 | 138 – 310 | 24 |

| Gr.2 | 50 | 345 | 40 – 65 | 275 – 450 | 20 |

| Gr.3 | 65 | 450 | 55 – 80 | 380 – 550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| Elementum | Density | Liquescens punctum | Distrahentes fortitudo | Cedant fortitudo (0.2% Offset) | Prolongatio |

| Titanium Gr.2 | 4.5 g/cm3 | 1665 °F (3030 °F) | Psi - 49900 , MPa - 344 | Psi - 39900 , MPa - 275 | 20 % |

| Titanium Gr.5 | 4.43 g/cm3 | 1632 °F (2970 °F) | Psi - 138000 , MPa - 950 | Psi - 128000 , MPa - 880 | 14 % |

Titanium Fasteners

| Gradus | Fe% | C% | N% | H% | O% | Al% | V% | Mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0.014 | 0.18 | - | - | - | - | - | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0.014 | 0.25 | - | - | - | - | - | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0.014 | 0.35 | - | - | - | - | - | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0.014 | 0.40 | - | - | - | - | - | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0.014 | 0.02 | 5.5 - 6.75 | 3.5 - 4.5 | - | - | - | BAL |

| Gr7 | 0.3 | 0.08 | 0.03 | 0.014 | 0.25 | - | - | - | - | 0.12 - 0.25 | BAL. |

| Gr9 | 0.25 | 0.08 | 0.03 | 0.014 | 0.15 | 2.5 – 3.3 | 2.0 - 3.0 | - | - | - | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0.014 | 0.25 | - | - | 0.2 - 0.4 | 0.6 - 0.9 | - | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0.014 | 0.13 | 5.5 - 6.75 | - | - | - | - | B |