Admisce Inconsutilem Pipe

OD:6-720MM

WT:0.5-120MM

Longitudo: 3-16M

Application:Petroleum, Chemical Engineering, Electricity, Boiler

Standard:ASTM A335/A335M, ASTM A213/213M, DIN17175-79, JIS3467-88, GB5310-95

Material: P5, T5, P11, P12, STFA22, P22, T91, T9, WB36

Tibia mixtura est quaedam fistulae ferreae inconsutilis, effectus eius multo altior quam generalis fistulae ferreae inconsutilis, quia hoc genus fistulae ferreae plus Cr, eius caliditas resistentia, caloris humilis resistentia, corrosio resistentia multo melior quam alia. Fistula ferri, ergo fistula stannum late in petroleo, aerospace, chemica, electrica potestate, boiler, militari et aliis industriis adhibetur.

| Productum | SEAMLESS / ERW / VIDERE ADMISSUS FERRUM PIPIS |

| Dimension | 6 mm - 1080 mm |

| Crassitudo | 1mm - 135 mm |

| Longitudo | 3 m - 12 m vel secundum exigentias clientium |

| Standard | ASTM GB DIN |

| Gradus ferro | A106/53/79/214/192/210 A/B/CST37.2/35.4/35.8/52/52.3/52.4/42/4510# 20# 45# P2, P12, P11, P22, P5, P9, P91T2 , T11, T5, T9, T22, 4140, 12CrMo, 15CrMo, 12Cr2Mo, 1Cr5Mo, 2CrMo4, 1Cr9Mo, 10CrMo910, etc. |

| Commercia verba | MAL/CIF/CFR |

| Pensio conditio | T/T, L/C |

| Partus portum | Tianjin, China |

| Tempus adferendi | X vel secundum realem quantitatem fistularum |

| Superficiem treatment | Nigra paintingVarnish painting3PEHot galvanizedor alia membrana secundum adinventionem tuam tubo |

| Finis fistularum | Beveled, plana, fila, pilei plastici |

| inspicienda | Examen ultrasonic, barathrum inspectio, hydrosttica probatio etc. |

| sarcina | Fasciculi solve vel secundum requisita tua |

| Testimonium | API 5L/5CT, ISO, PED etc. |

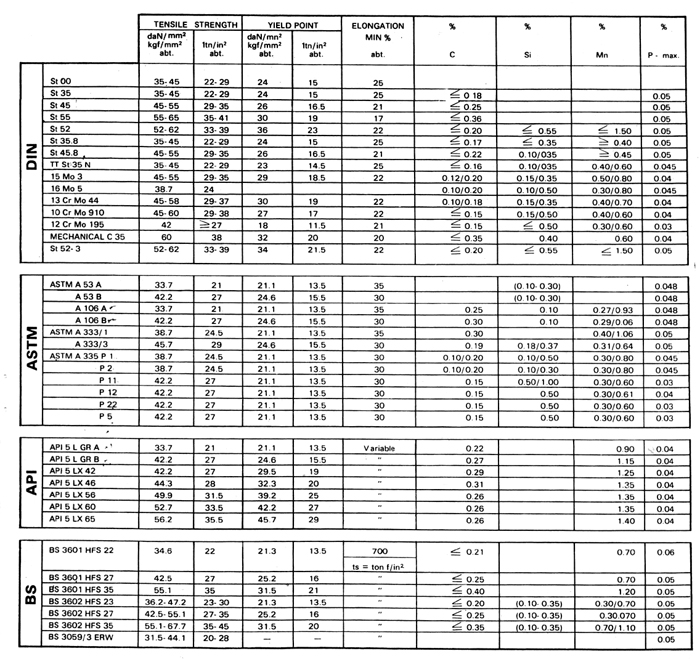

Compositio chemica

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.05-0.15 | 0.30-0.60 | 0.018 max | 0.018 max | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

Mechanica Properties

| Distrahens fortitudo, MPa | cede virtus, MPa | Prolongatio, % |

| 415 min | 205 min | 30 min |

Extra Diameter & Tolerantia

| ASTM A450 | calidum advolvit | Extra diametrum, mm | Tolerantia, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| Frigus Drawn | Extra diametrum, mm | Tolerantia, mm | |

| OD<25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1<OD<50.8 | ±0.20 | ||

| 50.8≤OD<63.5 | ±0.25 | ||

| 63.5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190.5 | +0.38/-0.64 | ||

| 190.5<OD≤228.6 | +0.38/-1.14 | ||

| ASTM A530 & ASTM A335 | NPS | Extra Diameter, inch | Tolerantia, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

Muri crassitudine & tolerantia

| ASTM A450 | calidum advolvit | Extra diametrum, mm | Tolerantia, % |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| Frigus Drawn | Extra diametrum, mm | Tolerantia, % | |

| OD≤38.1 | +20/-0 | ||

| OD>38.1 | +22/-0 | ||

| ASTM A530 | NPS | Extra Diameter, inch | Tolerantia, % |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

ASTM A335-nam Seamless Ferritic Alloy-Steel Pipe ad summus Temperature Service

ASTM A519-nam Seamless Carbon et Admisce Ferro Mechanica Tubing

ASTM A213-pro Seamless Ferritic et Austenitic Alloy-Steel Boiler, Super calefacientis, et Caloris Commutatio Tubuli

ASTM ASME (S)A-335/(S)A-335M Gradus et Chemical Compositio

| Gradus | UNS | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | - | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 4.00~6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 4.00~6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | - | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.018 | 0.011 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.018 | 0.011 | 0.50 | 8.50~9.50 | 0.30~0.60 |

Nota: (S)A335 P91 aliae compositionis chemicae sunt: V 0.18~0.25;N 0.030~0.070;Ni≤0.40;Al≤0.04 ;Nb 0.06~0.10

(S)A335 P92 alia compositio chemica sunt: V 0.15~0.25;N 0.030~0.070;Ni≤0.40;Al≤0.04 ;Nb 0.04~0.09;W 1.5~2.00 ;B 0.001~0.006

Nigra tunica , oleum / illitus , FBE, 2PE,3PE, galvanized etc. Packaging Detail: stipare in fasciculos vel ad huius postulationem