Channel

A36 Ferro Channel calido convolvitur, mitis chalybeis figura C fabricatur cum radiis intus angulis quae est apta omnibus structuris applicationibus, fabricandis, fabricandis et reparationibus generalibus.Ferro Channel late usus est in sustentatione industriae, instrumentis agriculturae, apparatu translationis, stratis salsurae, massarum, etc. Forma C-figura seu figuratio U-forma specimen est ad vim et rigiditatem super angulum ferreum additae, cum onus consilii tui verticalis vel horizontalis est.Figura haec chalybea facile est pactionem, incisam, formam et machinam cum propriis instrumentis et scientia.Metalla Depot nervum centeni magnitudinum canalis ferrei ad pretium Lupum in paratis ad navem precut et molendini longitudinum vel iubere id quod exigis consuetudini incidere ad Magnitudinem in parva vel magna quantitate iubere potes.A-36 Ferro Channel etiam praesto est in galvanized metam ad diuturnam corrosionis tutelam obductis.

| Ferrum calidum advolvit channel | |||

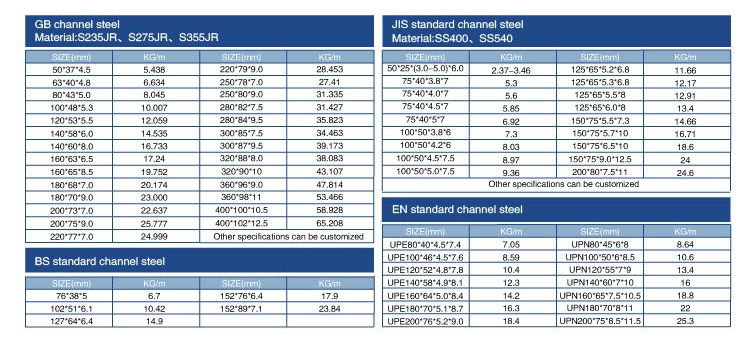

| Executive Standard | GB/T 707-1988 | JIS G 3192-2006 | DIN 1026-1:2000 |

| Steel Gradus | Q235B | SS400 | S235JR |

| General Size | 5# 50* 37* 4.5mm - 40B 400* 102* 12.5mm | 5# 50*25*3mm - 200*80*7.5mm | UPN140- UPN200 |

| Longitudo | 6m,10m,12m, vel petitionem emptoris sequi potest ut 5.5m,5.8m ad onerandas in vase. | ||

| commoda | 1. princeps qualitas2.summus dimensional accuracy3.sumptus peculi | ||

| Applicationem | Aedificium structuram, velum murum ipsum, machinamenta mechanica et vehiculum fabricandum, etc | ||

| Packaging | Professional export packaging vel secundum elit elit. | ||

| Frigus inflexio canalis chalybe | |||

| General Size | latitudo: 10-400mm, grossitudo:1-16mm | ||

| Longitudo | 6m,9m,12m, vel petitionem emptoris sequi potest ut 5.5m,5.8m ad onerandas in vase. | ||

| commoda | Constitue pro specificationibus quae ferrum canalem calidum revolvit, produci non potest.Specificatio et crassitudo discursum est secundum magnitudinem nativus | ||

ASTM A53/ASTM A573/ASTM A283 Gr.D/BS1387-1985/GB/T3091-2001,

GB/T13793-92, ISO630/E235B/JIS G3131/JIS G3106

| Gradus | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7.5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 – 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 – 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0.22 | 0. 24 -0 .26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

| A36 FERRUM FERRUM tolerances(+/-) | ||||||

| Channel Size | Profundum Channel | Latitudo Flange | Recta per X pedes | Longitudine +/- | Ex Quadratus | |

| Custom Cut | Standard | |||||

| 1/2 ad 1-1/2 | 1/32 | 1/32 | 1/4 | 1/16 | 1/4 | 1/32 |

| 1-1/2 ad 3 | 1/16 | 1/16 | 1/4 | 1/16 | 1/4 | 1/32 |

| 3 ad 7 | 3/32 | 1/8 | 1/4 | 1/8 | 1/4 | 1/32 |

| 7 ad 14 | 1/8 | 1/8 | 1/4 | 1/8 | 1/4 | 1/32 |

| super 14 | 3/16 | 1/8 | 1/4 | 1/8 | 1/2 | 1/32 |

| Valores tolerantiae hoc modo provisae sunt ad proposita tantum informatica et non praestanda. | ||||||